A kind of stone-plastic plate and its preparation method and stone-plastic door cover line

A door cover line and stone plastic technology, applied in the field of door cover line, can solve the problems of difficult adjustment, high construction cost, long construction period, etc., and achieve the effect of saving physical or material resources, easy installation process, and strong adhesion durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] A stone-plastic plate made of the following raw materials in parts by weight:

[0031] 100 parts of polyvinyl chloride, 110 parts of calcium carbonate, 6.8 parts of chlorinated polyethylene, 4 parts of polyethylene wax, 1 part of stearic acid, 2 parts of lead salt composite stabilizer, wherein the content of lead in the lead salt stabilizer is 60 %.

[0032] The preparation method of above-mentioned stone-plastic plate is as follows:

[0033] (1) Take the raw materials by weight and mix them uniformly;

[0034] (2) Heat the homogeneously mixed material to 120° C., and then stir to cool it down. During the heating process, stir while heating, and the stirring speed is 1200 r / min.

[0035] (3) The cooled material is heated and plasticized by an extruder, and then extruded to obtain a finished stone-plastic plate.

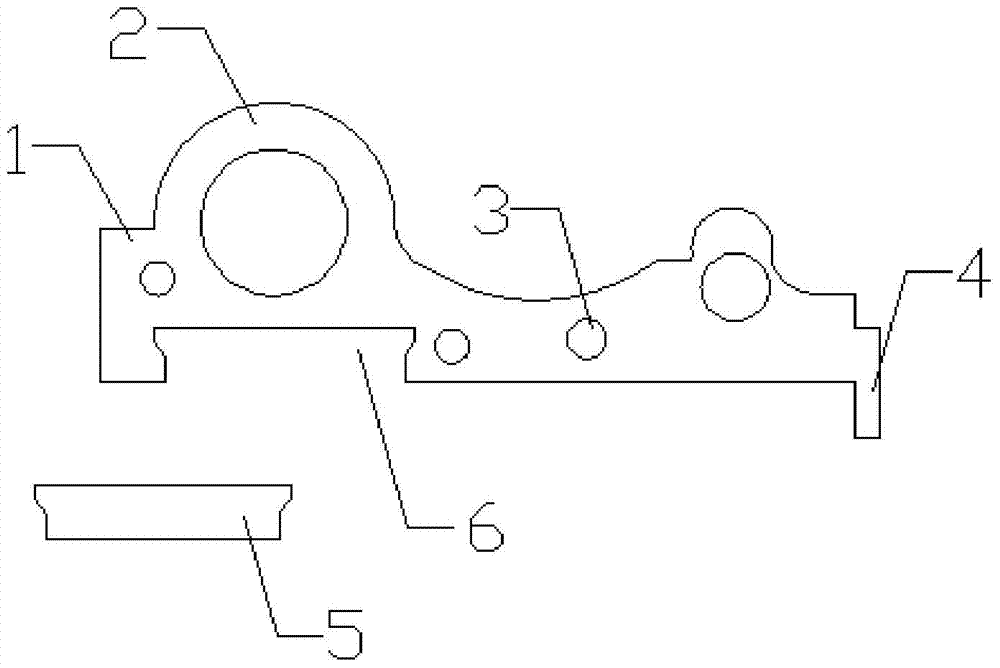

[0036] The above-mentioned stone-plastic plate is a stone-plastic door cover line prepared as a base material, including a door cover line main board 1, and...

Embodiment 2

[0038] A stone-plastic plate made of the following raw materials in parts by weight:

[0039] 50 parts of polyvinyl chloride, 200 parts of calcium carbonate, 6.1 parts of chlorinated polyethylene, 3.4 parts of polyethylene wax, 0.7 parts of stearic acid, 1.6 parts of lead salt composite stabilizer, wherein the content of lead in the lead salt stabilizer is 48 %.

[0040] The preparation method of above-mentioned stone-plastic plate is as follows:

[0041] (1) Take the raw materials by weight and mix them uniformly;

[0042] (2) Heating the homogeneously mixed material to 80° C., and then stirring to cool it down. During the heating process, stir while heating, and the stirring speed is 1400 r / min.

[0043] (3) The cooled material is heated and plasticized by an extruder, and then extruded to obtain a finished stone-plastic plate.

[0044] A stone-plastic door cover wire prepared from the above-mentioned stone-plastic plate as a base material, the structure of which is the s...

Embodiment 3

[0046] A stone-plastic plate made of the following raw materials in parts by weight:

[0047] 85 parts of polyvinyl chloride, 170 parts of calcium carbonate, 7.9 parts of chlorinated polyethylene, 3.1 parts of polyethylene wax, 0.5 parts of stearic acid, 1.1 parts of lead salt composite stabilizer, wherein the content of lead in the lead salt stabilizer is 21 %.

[0048] The preparation method of above-mentioned stone-plastic plate is as follows:

[0049] (1) Take the raw materials by weight and mix them uniformly;

[0050] (2) Heat the homogeneously mixed material to 103° C., and then stir to cool it down. During the heating process, stir while heating, and the stirring speed is 1000 r / min.

[0051] (3) The cooled material is heated and plasticized by an extruder, and then extruded to obtain a finished stone-plastic plate.

[0052] A stone-plastic door cover line prepared from the above-mentioned stone-plastic plate as a base material, the structure of which is the same as...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com