Sludge dehydrating agent and dehydrating method thereof

A kind of sludge dehydrating agent and sludge technology, applied in the direction of dehydration/drying/concentrated sludge treatment, etc., can solve the problems of increasing desalination, decolorization, equipment corrosion, etc., achieve enhanced flocculation performance, good reduction effect, and reduce follow-up The effect of the treatment process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

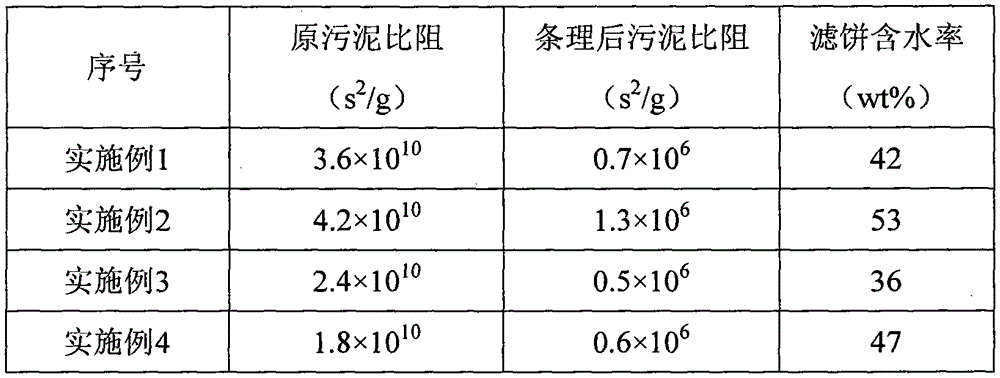

Examples

Embodiment 1

[0019] Sludge dehydrating agent, including Group A substance and Group B substance, said Group A substance is composed of the following raw materials in parts by weight, 10 parts of methacrylamide, 7 parts of acryloyloxyethyltrimethylammonium chloride , 25 parts of 2-acrylamide-2-methylpropanesulfonic acid, 16 parts of dimethylformamide, 3.5 parts of initiator;

[0020] The Group B substances are composed of the following raw materials in parts by weight: 7 parts of plant ash, 75 parts of quicklime, 15 parts of fly ash, and 2.5 parts of zinc oxide.

[0021] The initiator comprises the following materials in parts by weight, 1 part of diisopropyl peroxydicarbonate and 7 parts of potassium persulfate.

[0022] The preparation method of Group A substance is: use distilled water as solvent, methacrylamide, acryloyloxyethyltrimethylammonium chloride, 2-acrylamide-2-methylpropanesulfonic acid, dimethylformamide, initiator The solvent was dissolved and stirred, nitrogen was used as ...

Embodiment 2

[0031] Sludge dehydrating agent, including Group A substance and Group B substance, said Group A substance is composed of the following raw materials in parts by weight, 13 parts of methacrylamide, 5 parts of acryloyloxyethyltrimethylammonium chloride , 27 parts of 2-acrylamide-2-methylpropanesulfonic acid, 13 parts of dimethylformamide, 5 parts of initiator;

[0032] Said group B substances are composed of the following raw materials in parts by weight: 8 parts of plant ash, 70 parts of quicklime, 25 parts of fly ash, and 3 parts of zinc oxide.

[0033] The initiator comprises the following materials in parts by weight, 2 parts of diisopropyl peroxydicarbonate and 8 parts of potassium persulfate.

[0034] The preparation method of Group A substance is: use distilled water as solvent, methacrylamide, acryloyloxyethyltrimethylammonium chloride, 2-acrylamide-2-methylpropanesulfonic acid, dimethylformamide, initiator The solvent was dissolved and stirred, nitrogen was used as a ...

Embodiment 3

[0043] Sludge dehydrating agent includes Group A substances and Group B substances. The Group A substances are composed of the following raw materials in parts by weight, 11 parts of methacrylamide, and 8 parts of acryloyloxyethyltrimethylammonium chloride , 20 parts of 2-acrylamide-2-methylpropanesulfonic acid, 15 parts of dimethylformamide, 4 parts of initiator;

[0044] The Group B substances are composed of the following raw materials in parts by weight: 5 parts of plant ash, 80 parts of quicklime, 20 parts of fly ash, and 2.3 parts of zinc oxide.

[0045] The initiator comprises the following materials in parts by weight, 3 parts of diisopropyl peroxydicarbonate and 5 parts of potassium persulfate.

[0046] The preparation method of Group A substance is: use distilled water as solvent, methacrylamide, acryloyloxyethyltrimethylammonium chloride, 2-acrylamide-2-methylpropanesulfonic acid, dimethylformamide, initiator The solvent was dissolved and stirred, nitrogen was used...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com