Device and method for physical chemical treatment of reactive dye waste water

A technology for reactive dyes and wastewater, applied in chemical instruments and methods, multi-stage water/sewage treatment, water/sludge/sewage treatment, etc., can solve the problems of difficult removal and poor biodegradability, and achieve low production cost and convenient Popularization and application, good economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

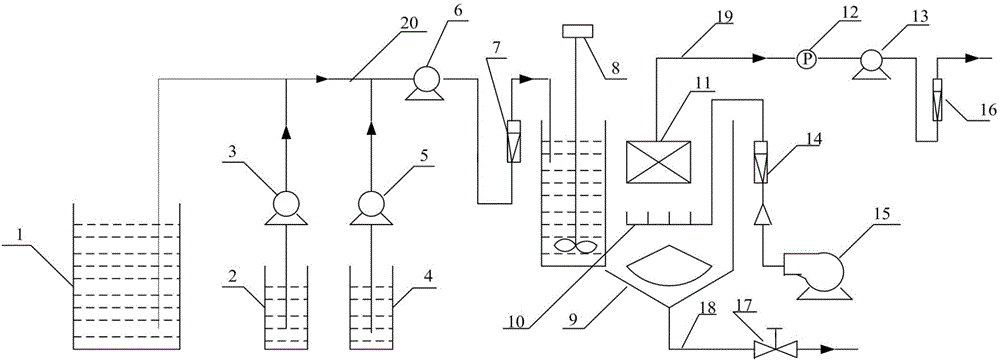

[0011] The main body of the physical and chemical treatment device for reactive dye wastewater described in this embodiment includes a water inlet tank 1, a coagulant dosing box 2, a coagulant dosing pump 3, an oxidant dosing box 4, an oxidant dosing pump 5, and a water inlet pump 6. Inlet flow meter 7, agitator 8, membrane coagulation reactor shell 9, microporous aerator 10, membrane module 11, pressure gauge 12, outlet pump 13, air flow meter 14, air compressor 15, Water outlet flow meter 16, mud discharge valve 17, mud discharge pipe 18, water outlet pipe 19 and water inlet pipe 20; water inlet tank 1 is connected with agitator 8, membrane coagulation reactor shell 9, microporous aeration through water inlet pipe 20 Membrane coagulation reactor composed of device 10, membrane module 11, pressure gauge 12, water outlet pump 13, air flow meter 14, air compressor 15, water outlet flow meter 16, sludge discharge valve 17, sludge discharge pipe 18 and water outlet pipe 19 The pi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com