Civilianized vacuum toilet wastewater collector

A technology of vacuum collection and toilet, which is applied in the direction of railway car body parts, toilet accessories, vehicle sanitary equipment, etc., can solve the problems of complex aircraft systems and great differences in vacuum equipment principles, and achieve low cost, simple structure, and low failure rate low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Below in conjunction with accompanying drawing, the present invention is described in detail.

[0016] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, and are not intended to limit the present invention.

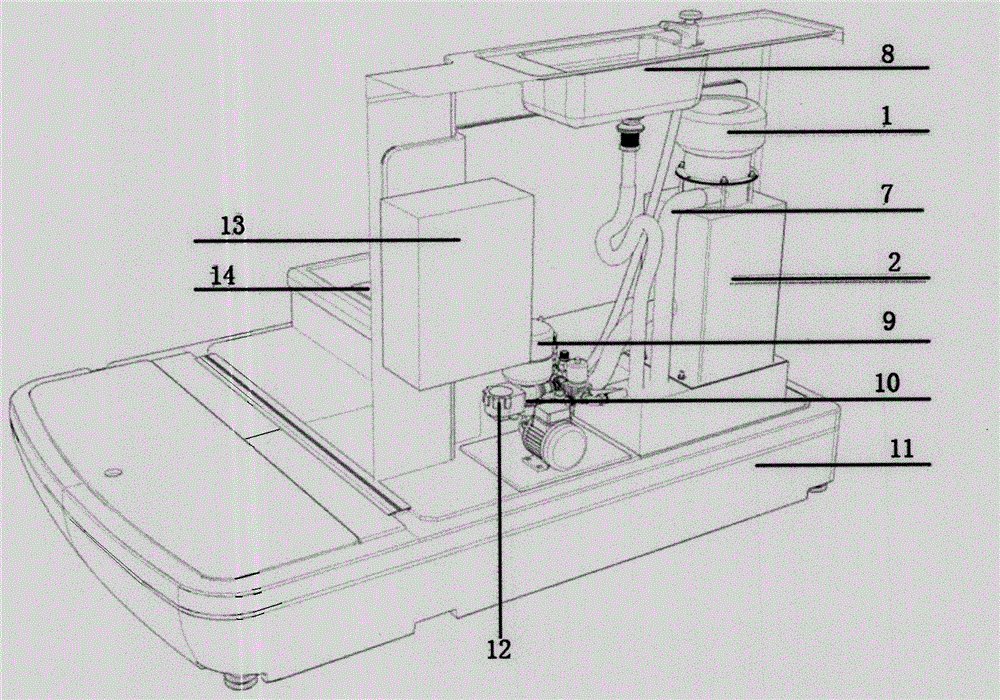

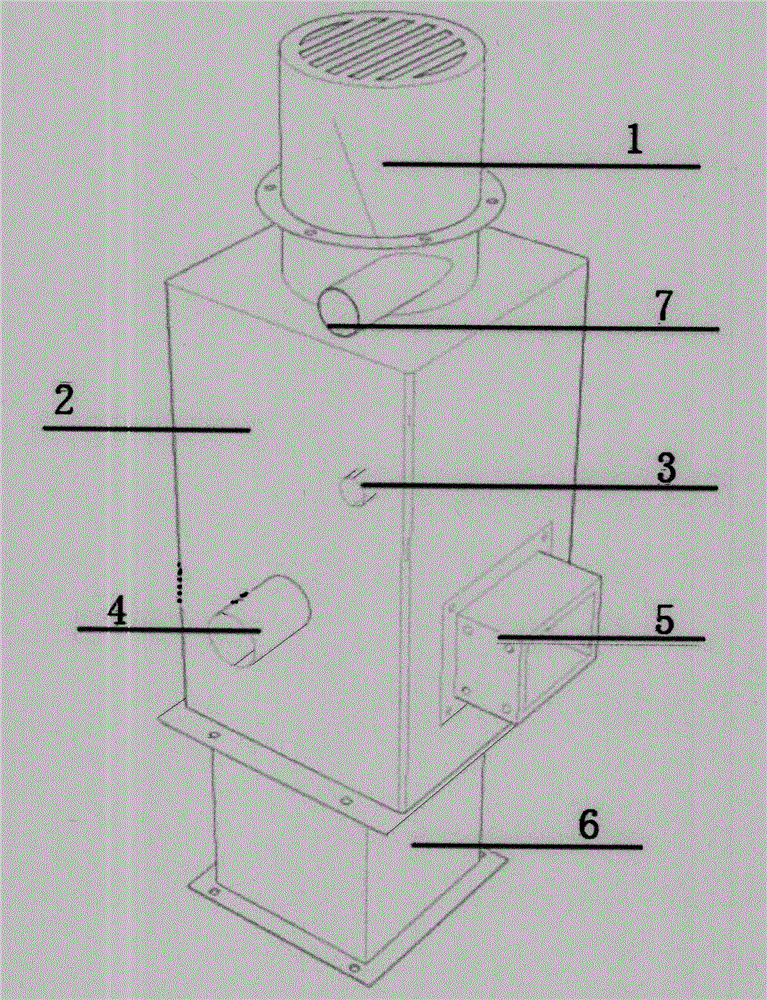

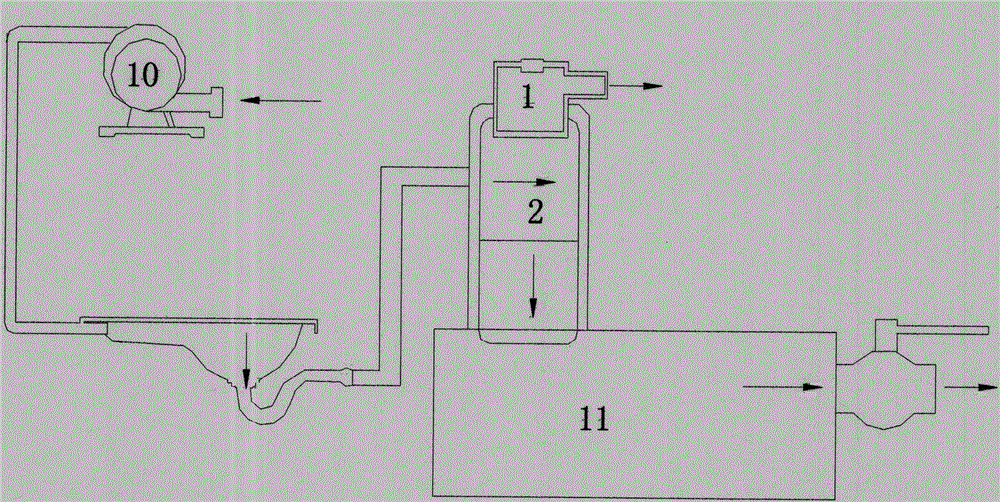

[0017] see Figure 1-Figure 4 , the specific embodiment adopts the following technical scheme: it includes a vacuum motor 1, a pressure vessel 2, a tank body cleaning pipeline 3, a cleaning tank body pipeline 4, a control panel mounting plate 5, a mounting base 6, a feces suction pipe 7, a pool 8, Water pump pressure tank 9, water pump 10, collection excrement box 11, water pump pressure gauge 12, electrical box 13, vacuum squatting pan 14, vacuum squatting pan 14 is ins...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com