Inserting and clamping type carton full-automatic folding machine

A fully automatic, plug-in technology, applied to paper/cardboard containers, container manufacturing machinery, containers, etc., can solve the problems of reduced strength of the packaging box, inconvenient opening of the box, slow speed of manual opening, etc., and achieve stable folding box quality , Folding fast, labor-saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

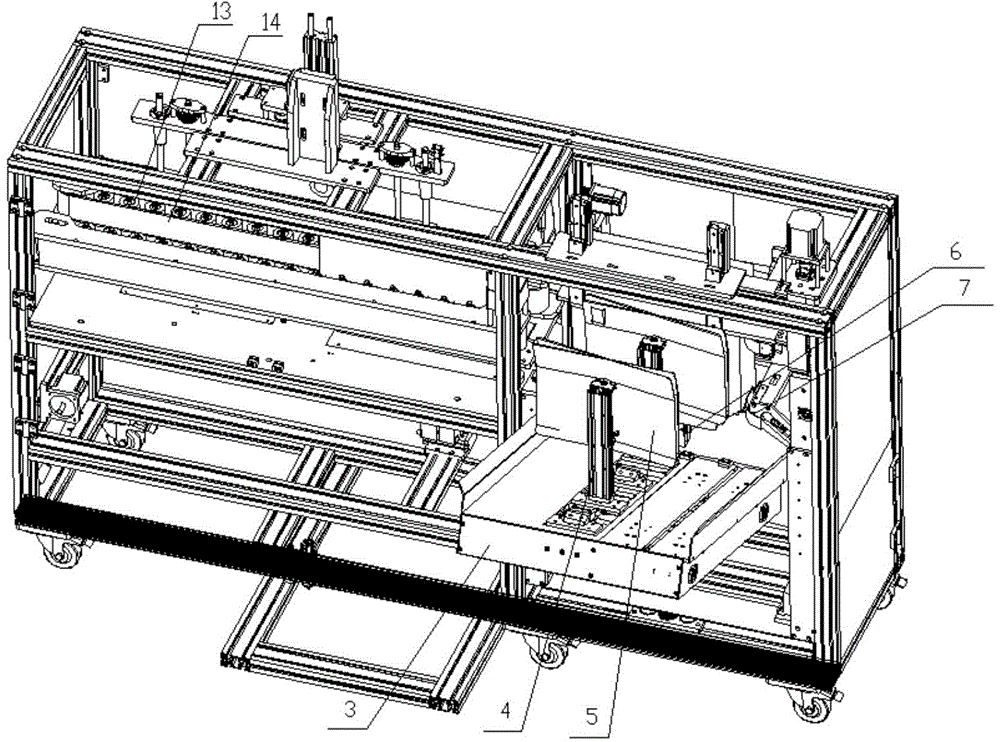

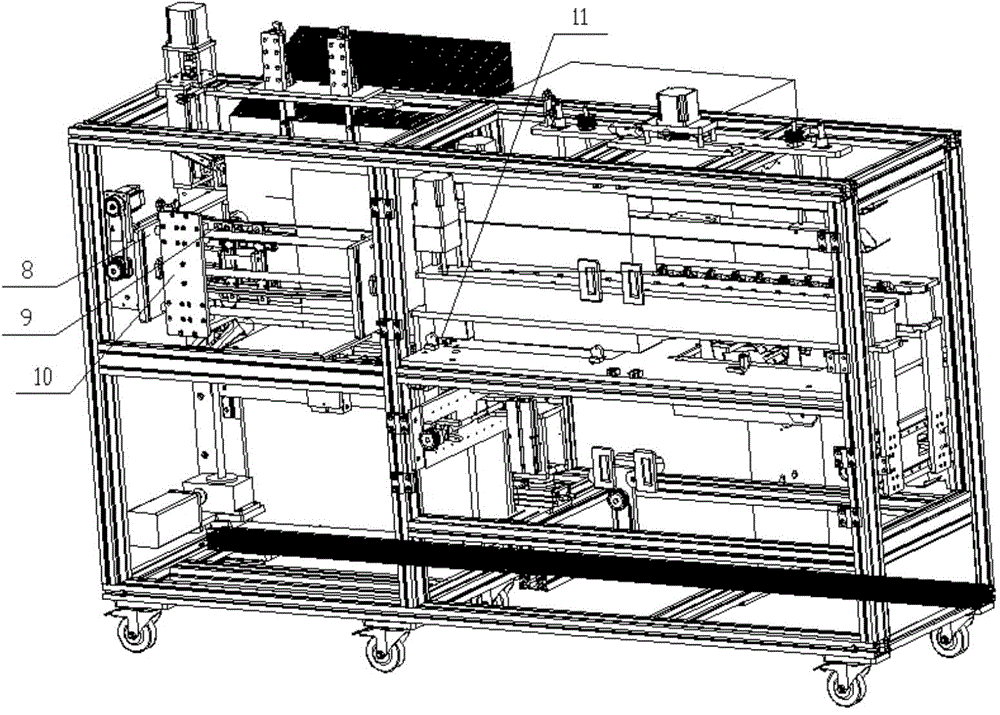

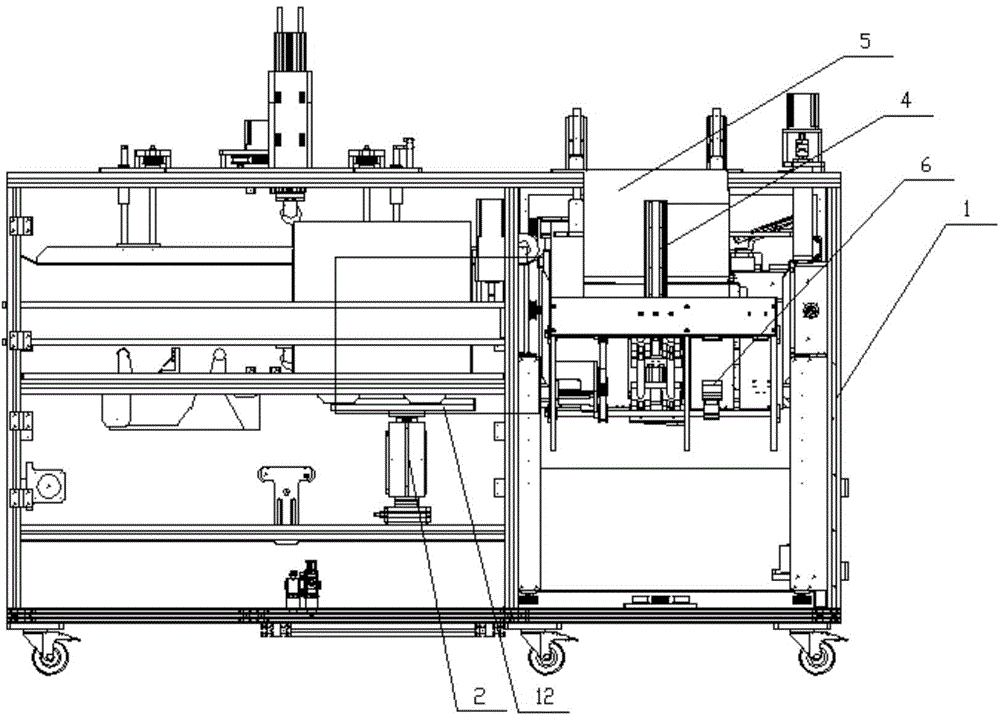

[0021] Embodiment: a plug-in type carton automatic folding machine, including a frame 1, a controller, a carton grabbing mechanism, a carton conveying mechanism, a first, second, third, and fourth edge folding mechanism and a pushing mechanism 2, wherein:

[0022] A carton feeding channel 3 is formed on the frame 1, and the cartons can enter the inside of the frame 1 along the carton feeding channel 3, and the carton grabbing mechanism can grab the cartons into the inside of the frame 1 and drive the cartons along the vertical feeding direction. Moving towards the other end of the carton to the carton conveying mechanism, the first folding mechanism can open the carton on the carton grabbing mechanism, and bend the carton along the first long side in front of the moving direction of the carton entering the inside of the frame 1, the second The second folding mechanism can bend the first short side of one end of the carton perpendicular to the first long side, the carton conveyi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com