Automatic hot stretching reprocessing method of LLDPE pipe

A technology for reprocessing and pipes, which is applied in the field of automatic hot drawing and reprocessing of LLDPE pipes, can solve the problems of unfavorable mass production, low efficiency, and inconvenient control of product quality, etc., and achieve the benefits of mass production, high efficiency of automatic processing, and easy control of products quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

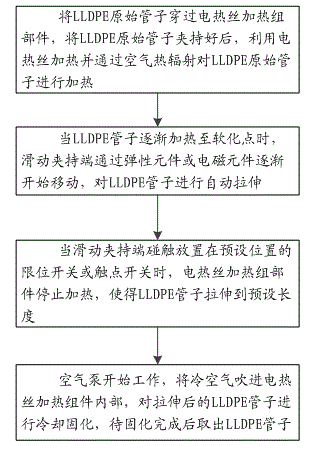

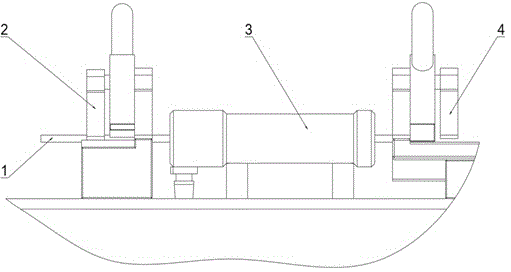

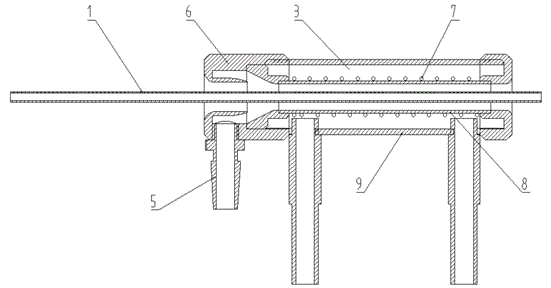

[0032] In Embodiment 1, a method for automatic hot drawing and reprocessing of LLDPE pipes is provided, please refer to Figure 1-Figure 6 , the method includes:

[0033] Pass the original LLDPE pipe through the electric heating wire heating group, and after clamping the original LLDPE pipe, use the electric heating wire to heat and heat the original LLDPE pipe through air heat radiation;

[0034] When the LLDPE pipe is gradually heated to the softening point, the sliding clamping end gradually starts to move through the elastic element or the electromagnetic element, and the LLDPE pipe is automatically stretched;

[0035] When the sliding clamping end touches the limit switch or contact switch placed at the preset position, the heating wire heating group part stops heating, so that the LLDPE pipe is stretched to the preset length;

[0036] The air pump starts to work, blowing cold air into the heating element of the electric heating wire, cooling and solidifying the stretched ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com