Automatic replacement control system and method for line drop switch based on laser technology

A drop switch and control method technology, applied in overhead lines/cable equipment, manufacturing tools, manipulators, etc., can solve problems such as loss of texture information, difficulty in accurately controlling the penetration of bolts into bolt apertures, and the inability of control systems to achieve target tracking, etc. Achieve the effect of reducing difficulty and facilitating positioning and tracking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0053] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

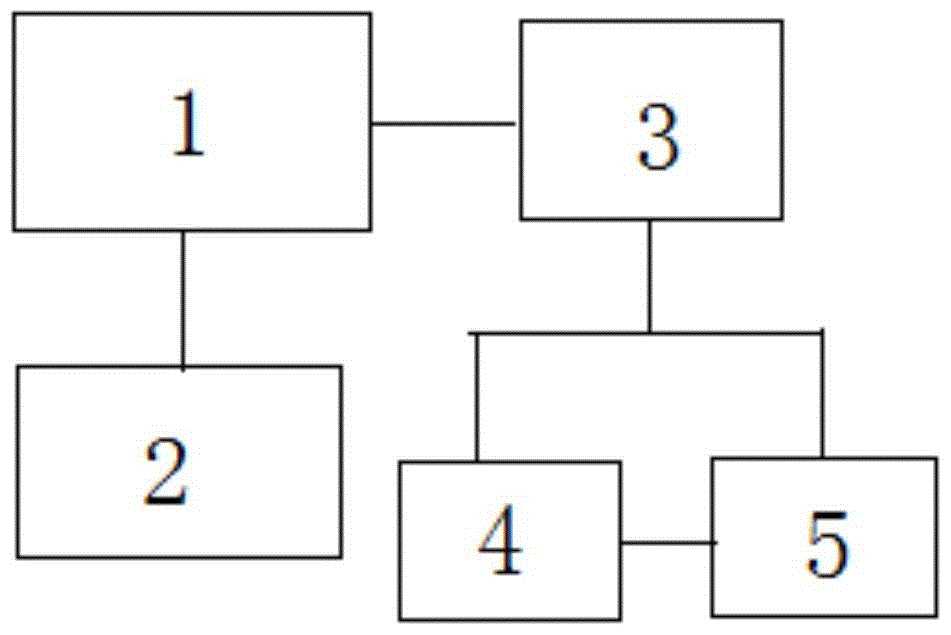

[0054] Such as Figure 1-2As shown, the line drop switch automatic replacement control system based on laser technology is characterized in that it includes:

[0055] Robot control unit 1: used to receive data from the data processing center and send control commands to the robotic arm control unit;

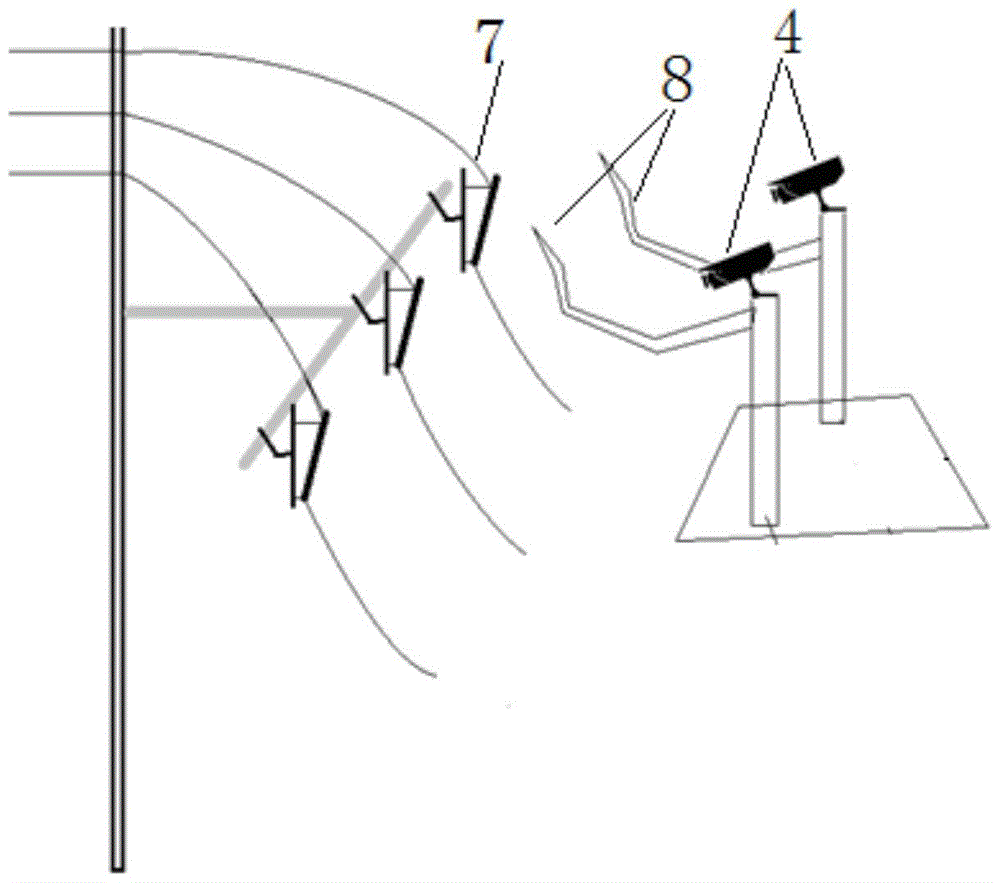

[0056] Manipulator control unit 2: used to control the manipulator 8 of the robot to replace the drop switch 7 by tightening or unscrewing the bolt 9 with identification information;

[0057] Laser positioning module 4: used to obtain the three-dimensional point cloud information of the front end of the mechanical arm 8 and transmit the information to the data processing center;

[0058] Target tracking module 5: Use the 3D point cloud information collected by the laser positioning module to calculate the movement of the current target of interest in rea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com