Drop type switch replacing control system and method based on high-voltage live working robot

A technology of operating robots and drop switches, which is applied in manipulators, manufacturing tools, metal processing, etc., can solve the problems of losing texture information, the control system is not suitable for target tracking, and it is difficult to accurately control the bolts extending into the bolt hole, etc., so as to reduce the difficulty Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0067] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

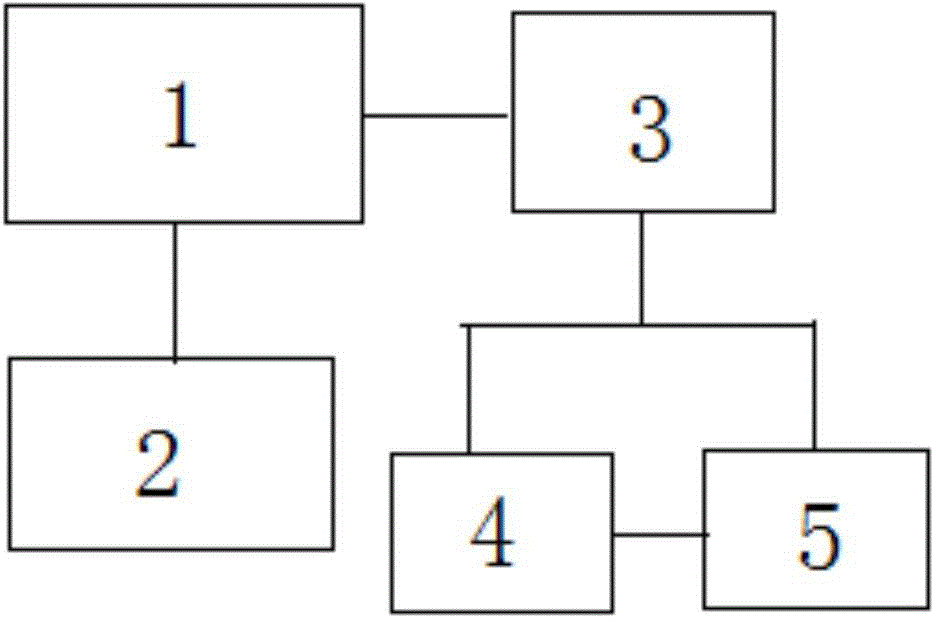

[0068] Such as Figure 1-2 As shown, a drop switch automatic replacement control system based on a high-voltage live working robot is characterized in that it includes:

[0069] High-voltage live working robot control unit 1: used to receive data from the image data processing center and send control commands to the robotic arm control unit;

[0070] Manipulator control unit 2: used to control the manipulator 8 of the robot to replace the drop switch 7 by tightening or unscrewing the bolt 9 with identification information;

[0071] Vision module 4: used to obtain the image of the front end of the mechanical arm 8 and transmit the image to the image data processing center; the cross binocular camera 6 is used to obtain the image of the front end of the mechanical arm 8 to simulate the binocular vision function of the human eye, and the cross binocular ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com