Moment or rolling bearing arrangement having sensor system

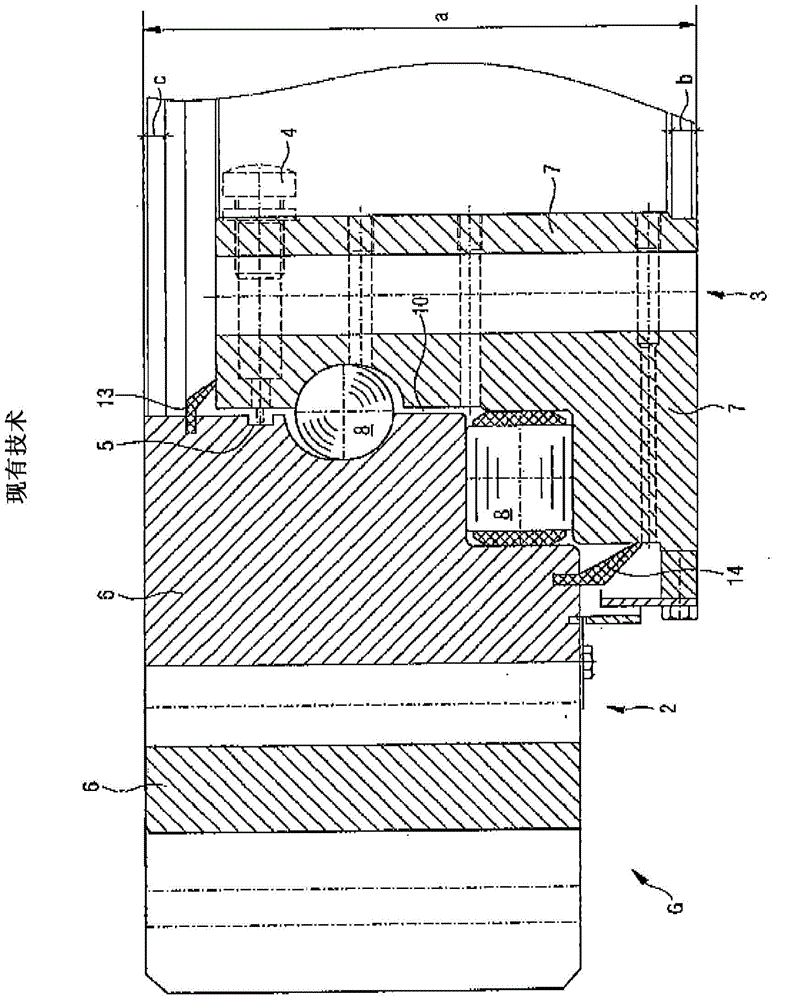

A technology of bearing devices and rolling bearings, which is applied in the direction of measuring devices, electrical devices, instruments, etc., and can solve the problems of unreliable sensing of axial offsets, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The individual stated features, details, advantages and effects of the present invention emerge from the following description of preferred embodiments of the present invention in conjunction with the following drawings.

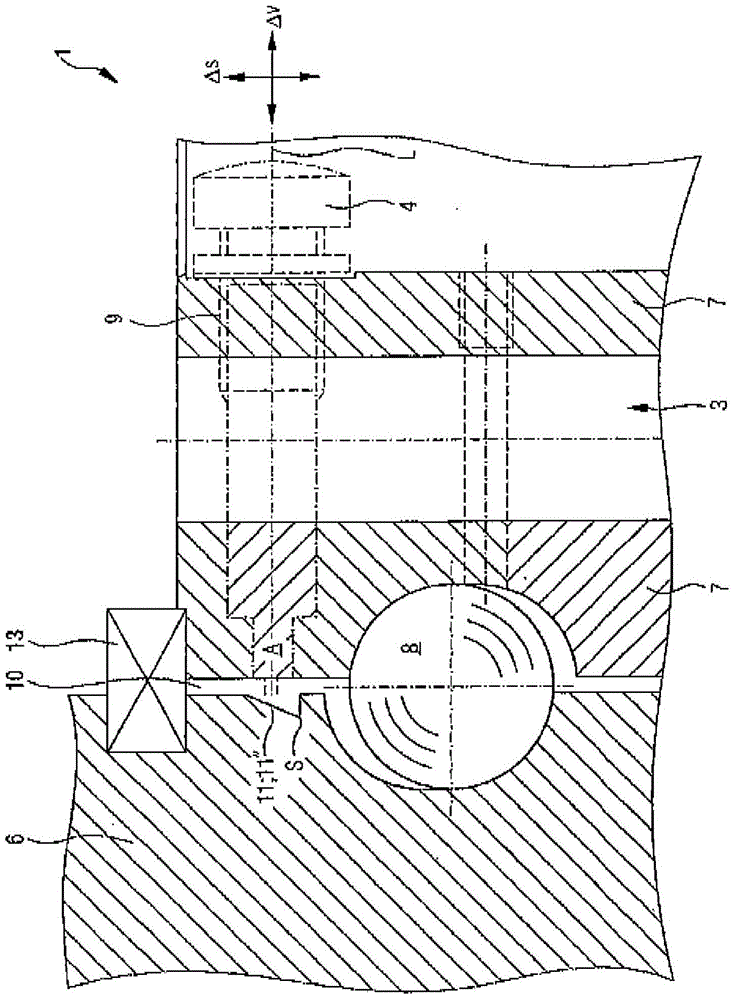

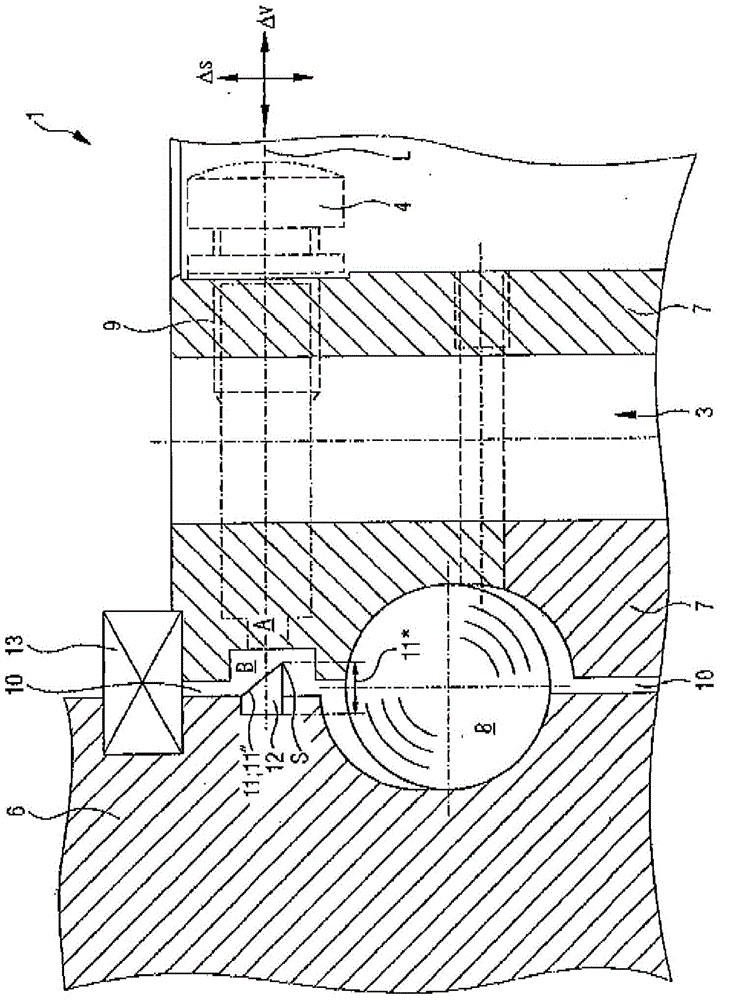

[0031] figure 2 A non-stepped contour or geometry 11 is shown, in particular a v-shaped or ramp-like contour in the bearing ring 6 opposite the distance sensor 4 . In this advantageous first embodiment of the invention, the sensing or detection end of the distance sensor 4 in the bearing ring is connected to the continuously changing contour or geometry in the axial direction in the opposite bearing ring 11" relative to each other.

[0032] figure 2 It also exemplifies the following design methods:

[0033] This non-stepped geometry is in figure 2 different from the prior art (see figure 1 ) in the form of a ramp 11". This has the particular advantage that when one bearing ring is offset in the axial direction relative to the other, the end A ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com