Vehicular brake hydraulic pressure controller

A brake hydraulic pressure and control device technology, applied in the direction of brakes, brake components, vehicle parts, etc., to achieve the effect of saving space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

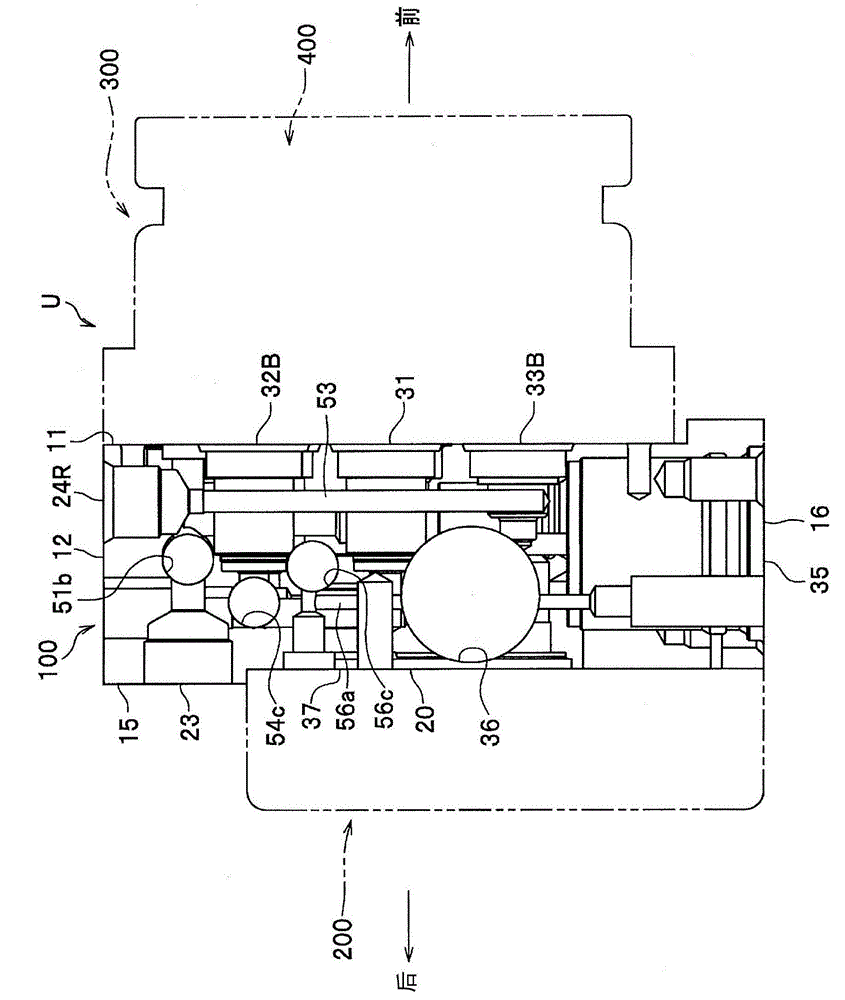

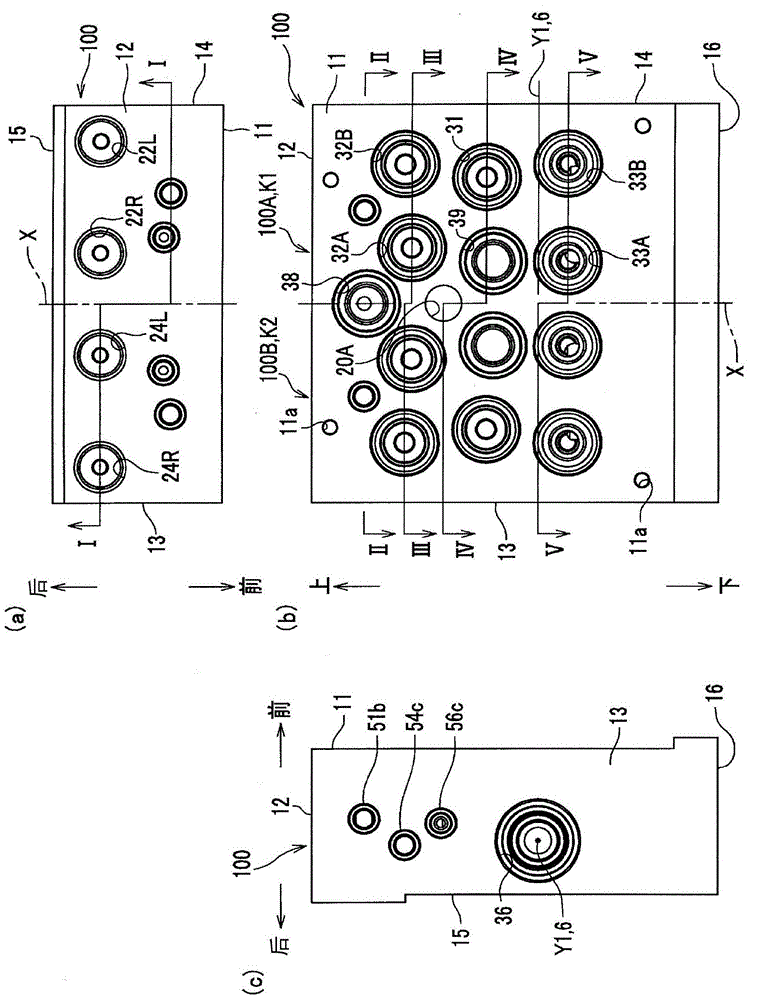

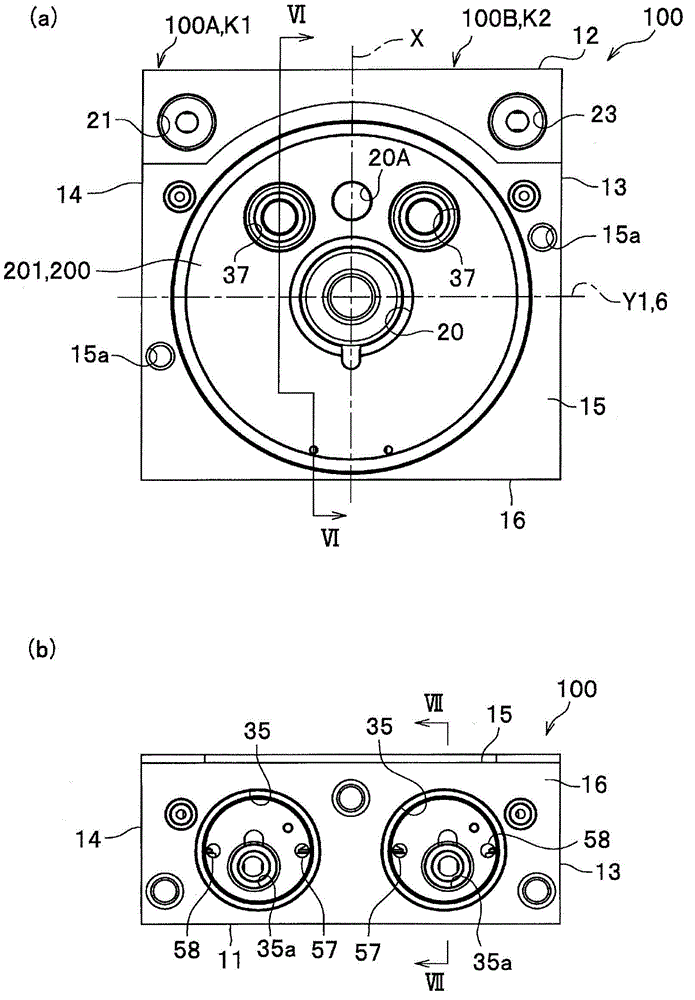

[0048] Hereinafter, modes for implementing the present invention will be described in detail with reference to the drawings. It should be noted that, in the description, the same reference numerals are attached to the same elements, and overlapping descriptions are omitted. In addition, in the following description, the term "up and down" is used with reference to the state where the inlet port 21, the outlet port 22L, etc., which will be described later, of the base body 100 are up and the pair of reservoirs 5 is down, but this is not necessarily the case. Consistent with the actual setting state.

[0049] Such as figure 1 As shown, the vehicle brake fluid pressure control device (hereinafter referred to as "brake fluid pressure control device") U of this embodiment is used in four-wheeled vehicles and the like, and includes: a base 100; The motor 200 (electric motor) on (the other side, the motor installation surface); the controller housing 300 assembled on the front surf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com