Ship inverter system

A technology for inverters and ships, applied in control systems, output power conversion devices, electrical components, etc., can solve the problems of complicated configuration and high proportion of space occupied in the ship, and achieve the optimization of the number of units, space saving, and reduction of Effect of magnetizing inrush current

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

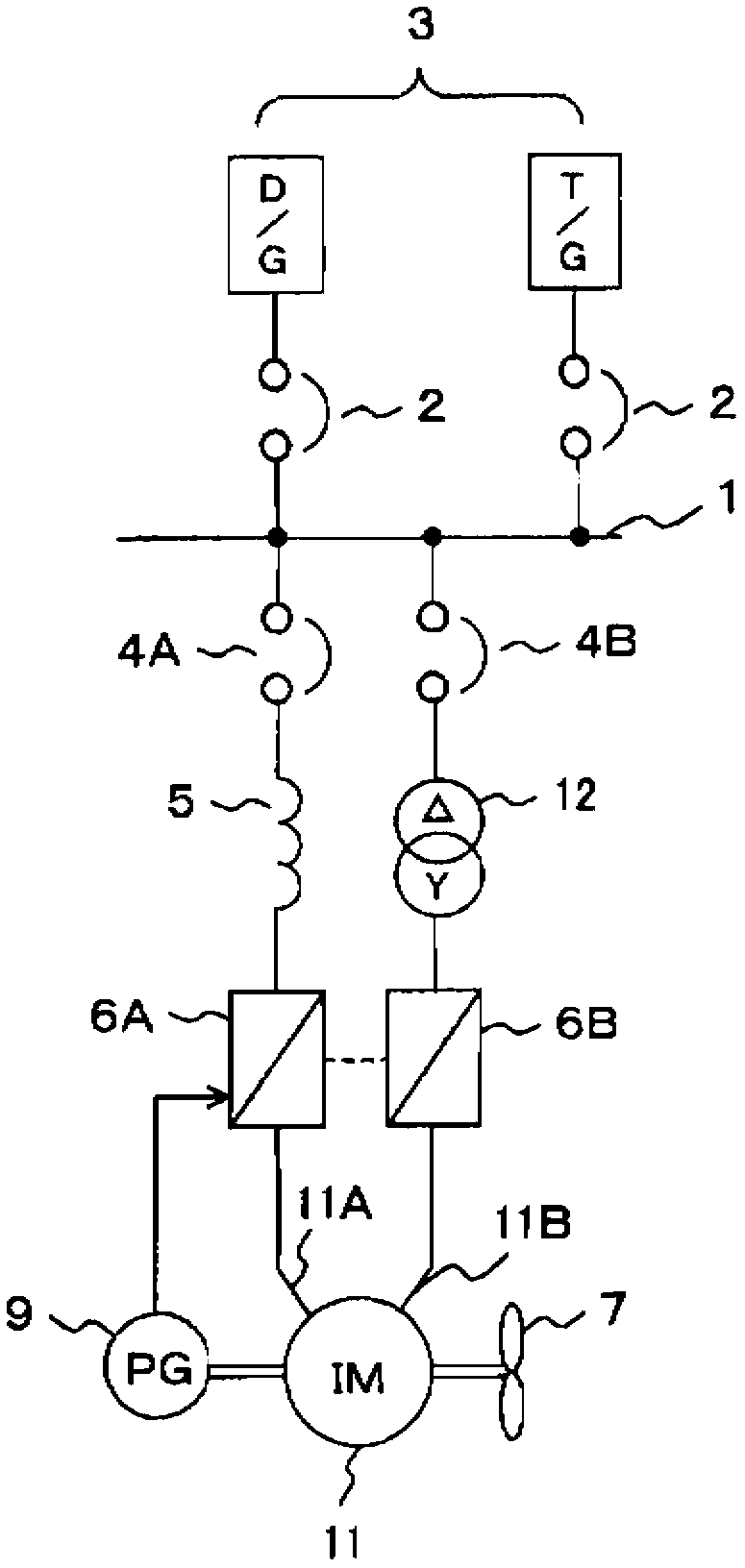

[0027] refer to figure 1 Embodiment 1 of the present invention will be described with reference to the configuration diagram of the marine inverter system shown.

[0028] (structure)

[0029] exist figure 1 In this embodiment 1, the marine inverter system and Figure 5 The difference of the marine inverter system shown in is that instead of the three-phase three-winding transformer 10, an AC reactor 5 and a three-phase single-winding transformer (△-Y type) 12 are used, and the power supply of the AC reactor 5 The side terminal is connected to the inboard bus 1 via the load-side circuit breaker 4A, and the load-side terminal is connected to the power-side terminal of the inverter 6A, thereby constituting the first power supply system; and, the power-side terminal of the three-phase single-winding transformer 12 It is connected to the inboard bus 1 via the load-side circuit breaker 4B, and the load-side terminal is connected to the power-side terminal of the inverter 6B, th...

Embodiment approach 2

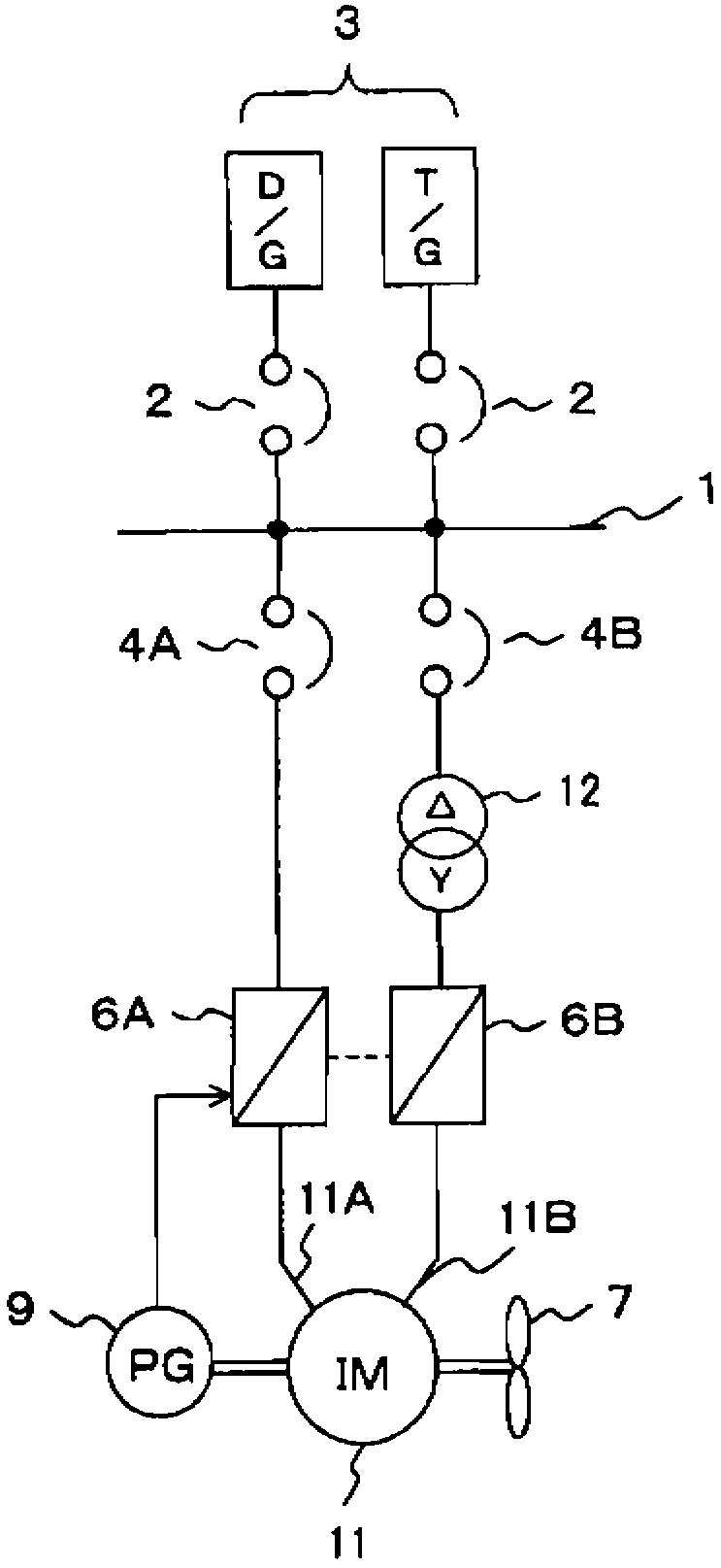

[0036] Next, refer to figure 2 Embodiment 2 of the present invention will be described with reference to the system configuration diagram shown.

[0037] exist figure 2 In this Embodiment 2, the difference from the above-mentioned Embodiment 1 is that, from figure 1 The system shown removes the AC reactor 5 to directly connect the power supply side terminal of the main side inverter 6A to the bus 1 in the ship, and the other structures are the same as figure 1 same.

[0038] In the case of Embodiment 2, although the harmonic suppression effect is slightly inferior to that of Embodiment 1 due to the removal of the AC reactor 5, the reduction effect of the equipment cost and the space saving in the ship due to the removal of the AC reactor 5 The effect of transformation is very high.

Embodiment approach 3

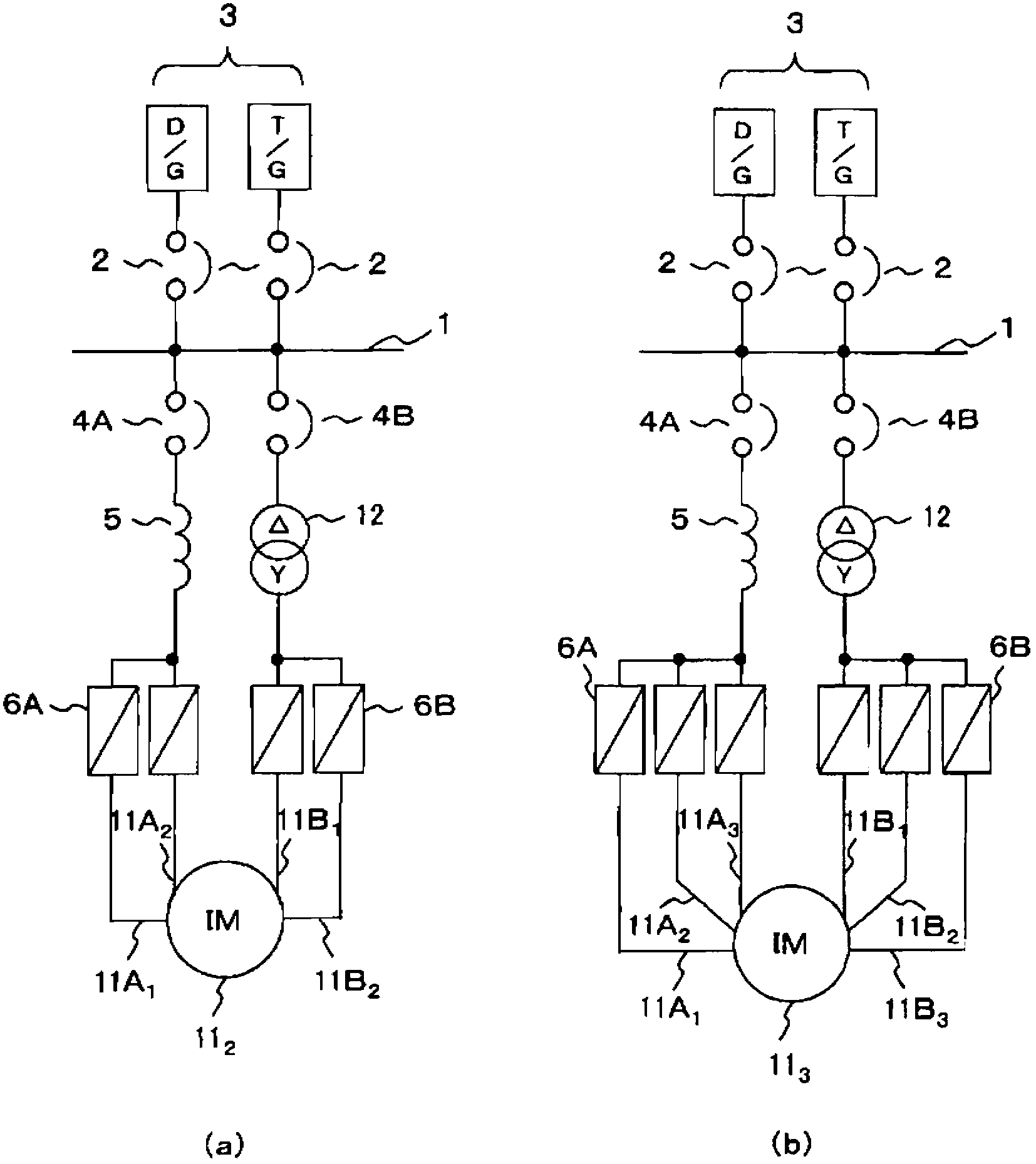

[0040] In the above embodiment 1 ( figure 1 ) and Embodiment 2 ( figure 2 ), a double-winding motor is used as the multi-winding motor 11, but the multi-winding motor is not limited to the double-winding type, and other multi-winding motors may be used.

[0041] image 3 (a) is the application of four-winding motor 11 2 The system structure diagram of the case, image 3 (b) is the application of six-winding type motor 11 3 The system structure diagram of the case. In addition, in image 3 The propeller 7, the speed detector 9, etc. are omitted in . exist image 3 In either of the systems (a) and (b), the stator windings and the inverters of the propulsion motor 11 are divided into two groups, whereby electric power is supplied to the propulsion motor using two systems.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com