Thermophotovoltaic power generation device and method during continuous casting process

A technology of thermal photovoltaic cells and castings, applied in the field of thermal photovoltaic power generation devices in the continuous casting process, can solve the problems of large heat exchange temperature difference between castings and cooling water, heat loss, heat depreciation utilization, etc., to achieve low power generation costs, small heat dissipation losses, Good cooling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] 1. Device

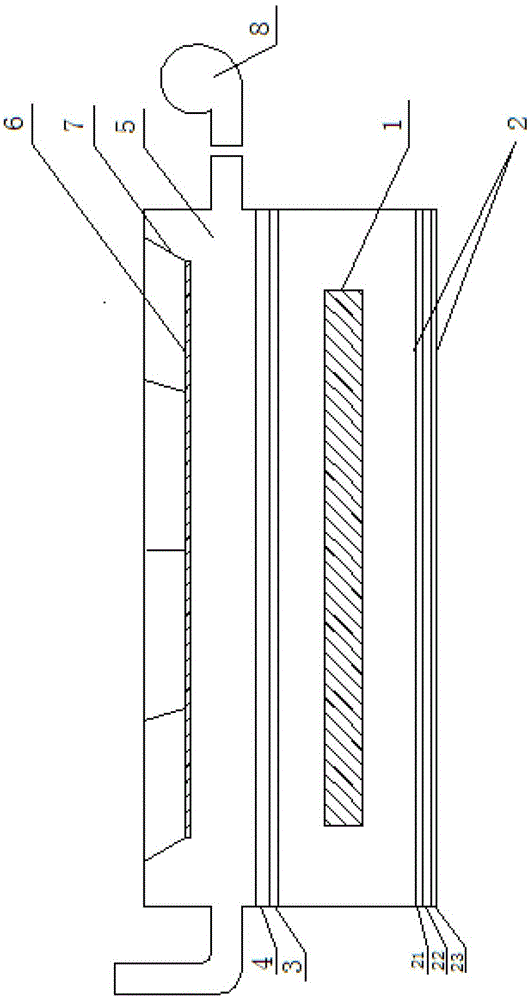

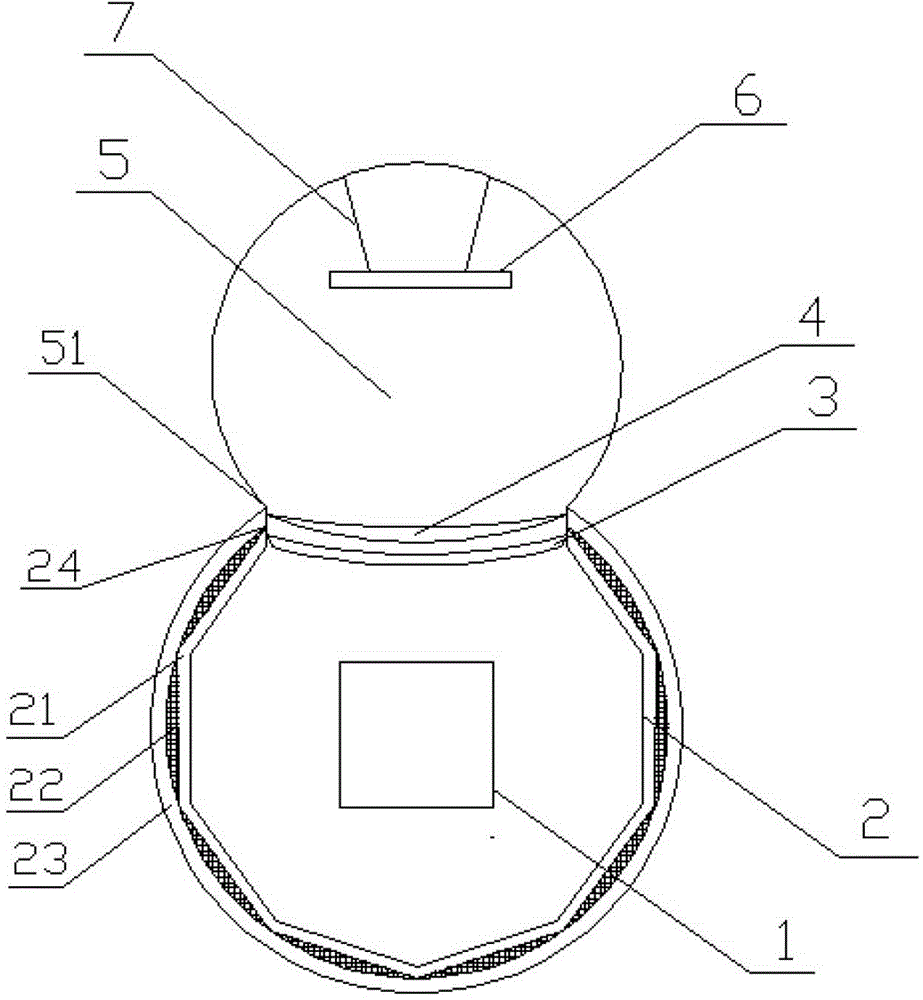

[0023] Such as figure 1 , figure 2 As shown, the present invention is a thermal photovoltaic power generation device for continuous casting process, which includes high temperature casting 1, reflecting wall 2, optical filter assembly 3, linear Fresnel lens assembly 4, cooling air channel 5, liquid immersion thermal photovoltaic Battery panel assembly 6, bracket 7, cooling fan 8.

[0024] The high-temperature casting 1 is a continuously moving casting that is pulled out from the mold during the continuous casting process until it is cut; the reflecting wall 2 is a bendable cylindrical cavity structure, and the reflecting wall 2 surrounds the high-temperature casting 1 in it Inner cavity, and the central axis of the reflective wall 2 is consistent with the central axis of the high-temperature casting 1. The reflective wall 2 has a three-layer structure, the innermost layer is a transmission material 21 made of high-purity quartz glass, and the middle layer is ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com