MOM capacitor and capacitance adjusting method

An adjustment method and capacitor technology, applied in the field of capacitors, can solve problems such as inability to achieve adjustment, and achieve the effect of saving adjustment costs and accurate analog circuits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

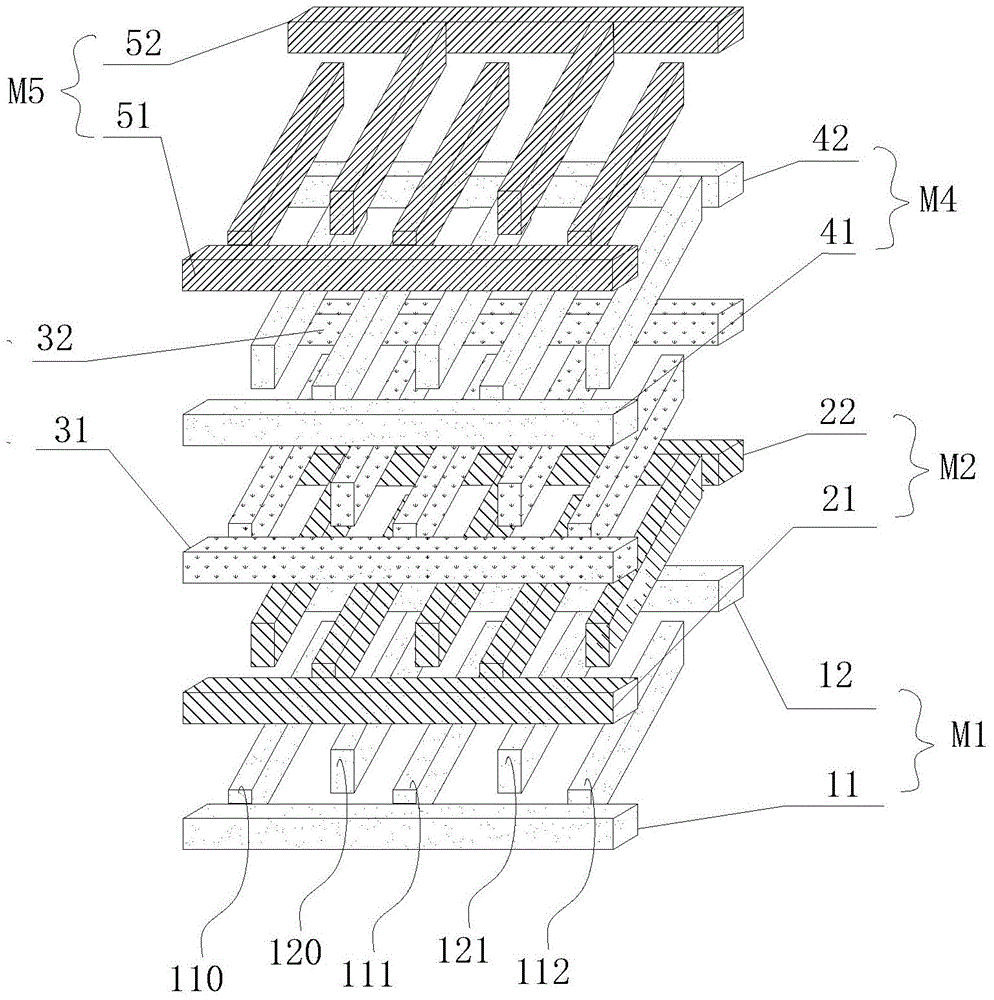

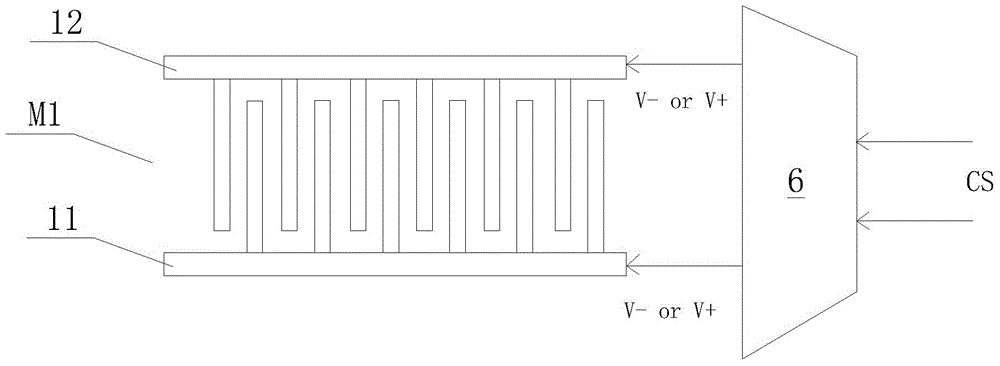

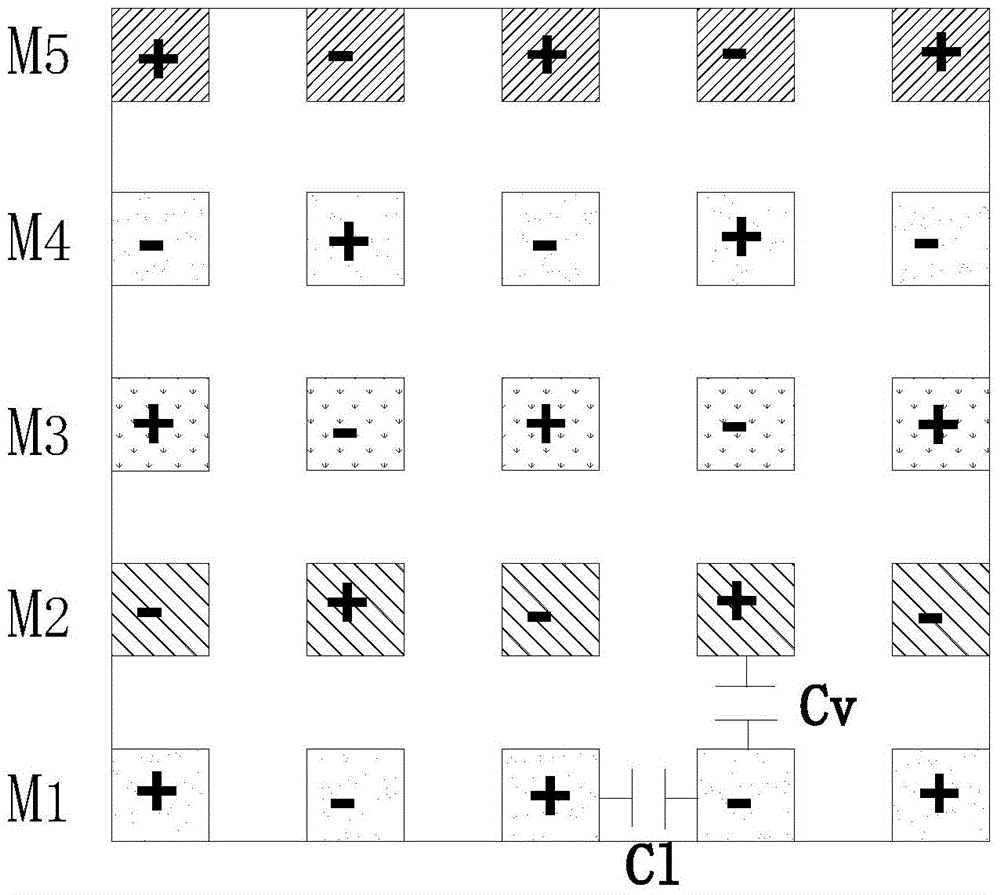

[0038] Such as image 3As shown, the first electrode 11 applied to the first metal layer M1 has a positive voltage, and the second electrode 12 has a negative voltage, so that the positive and negative polarities of each electrode finger of the first metal layer M1 are shown from left to right in the figure. Positive, negative, positive, negative, positive. A negative voltage is applied to the first electrode 21 of the second metal layer M2, and a positive voltage is applied to the second electrode 22, so that the positive and negative polarities of each electrode finger of the second metal layer M2 are shown as negative and positive from left to right in the figure. , negative, positive, negative. A positive voltage is applied to the first electrode 31 of the third metal layer M3, and a negative voltage is applied to the second electrode 32, so that the positive and negative polarities of each electrode finger of the third metal layer M3 are shown as positive and negative fr...

Embodiment 2

[0041] Such as Figure 4 As shown, the first electrode 11 applied to the first metal layer M1 has a positive voltage, and the second electrode 12 has a negative voltage, so that the positive and negative polarities of each electrode finger of the first metal layer M1 are shown from left to right in the figure. Positive, negative, positive, negative, positive. A positive voltage is applied to the first electrode 21 of the second metal layer M2, and a negative voltage is applied to the second electrode 22, so that the positive and negative polarities of each electrode finger of the second metal layer M2 are shown as positive and negative from left to right in the figure. , positive, negative, positive. A positive voltage is applied to the first electrode 31 of the third metal layer M3, and a negative voltage is applied to the second electrode 32, so that the positive and negative polarities of each electrode finger of the third metal layer M3 are shown as positive and negative ...

Embodiment 3

[0044] Such as Figure 5 As shown, the first electrode 11 applied to the first metal layer M1 has a positive voltage, and the second electrode 12 has a negative voltage, so that the positive and negative polarities of each electrode finger of the first metal layer M1 are shown from left to right in the figure. Positive, negative, positive, negative, positive. A negative voltage is applied to the first electrode 21 of the second metal layer M2, and a positive voltage is applied to the second electrode 22, so that the positive and negative polarities of each electrode finger of the second metal layer M2 are shown as negative and positive from left to right in the figure. , negative, positive, negative. A positive voltage is applied to the first electrode 31 of the third metal layer M3, and a negative voltage is applied to the second electrode 32, so that the positive and negative polarities of each electrode finger of the third metal layer M3 are shown as positive and negative ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com