PCB test method for CAN bus body controller

A CAN bus, body controller technology, applied in the field of auto parts, can solve the problems of high resource consumption, complex circuit layout, large uncertainty of open-loop control, etc., to achieve strong certainty, simple manufacturing and processing, and enhanced anti-interference. effect of ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

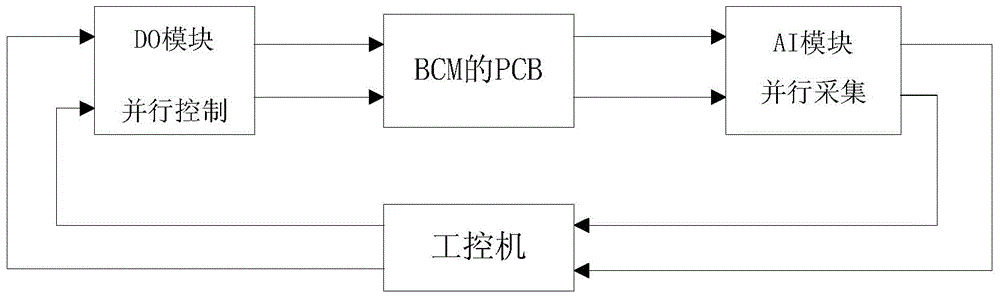

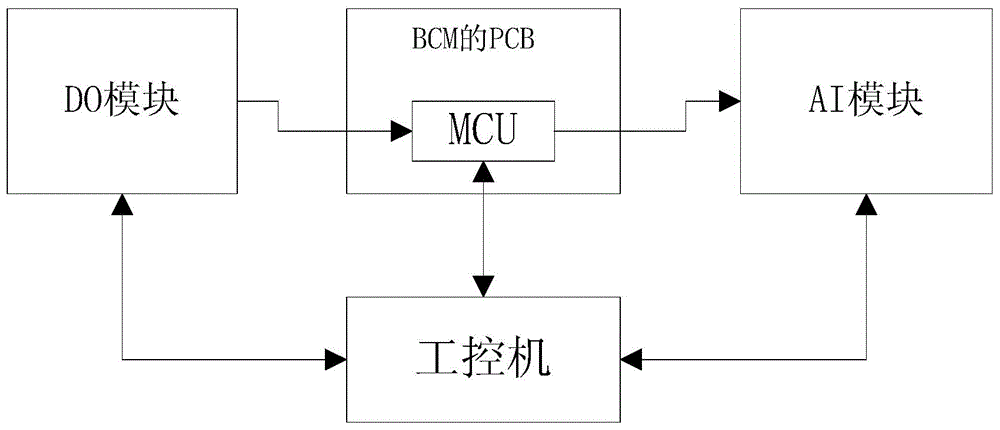

[0028] Such as figure 2 As shown, a test method for the BCM body controller of a car with a CAN bus, pre-burns a set of test programs for the main MCU of the test, adds the main MCU to a specially built CAN control network, and follows a customized communication mechanism. The control network includes

[0029] CAN network terminal name

CAN network interrupt ID

PC upper computer

0X30

control center

0X20

DO module

0X01-0X03

AI module

0X06-0X07

Tested BCM

0X40

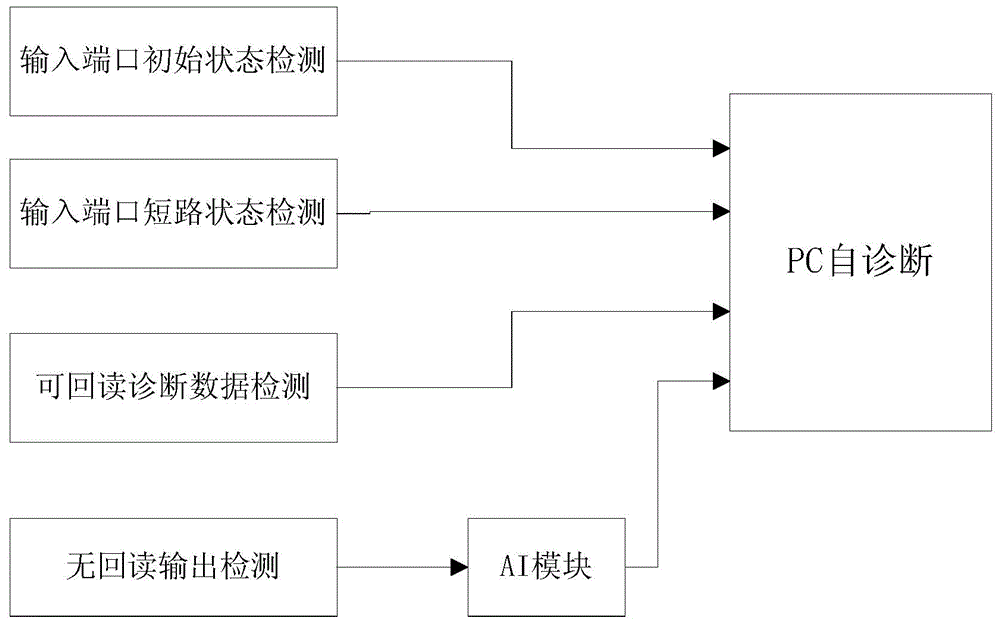

[0030] The upper computer PC performs self-diagnosis and detection through the CAN main control MCU, and the MCU reads all input port information and input port short-circuit status, and the judgment results are sent to the upper computer. Read the diagnostic data port that can be read back and send it to the upper computer for judgment. For the data port without read back, send a synchronization signal through the CAN and AI module, and the AI ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com