Curve contour error compensation adjustment control system and error compensation method

A Contour Error, Adjustment Control Technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

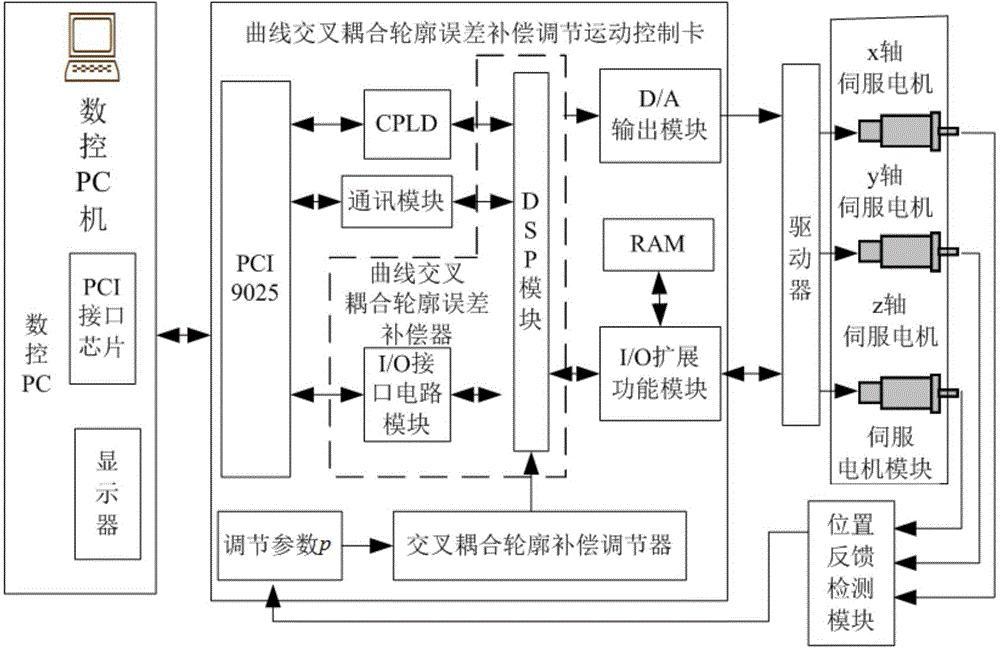

[0093] This embodiment provides an adjustment control system for curve cross-coupling contour error compensation, such as figure 1 As shown, it includes CNC PC, curve cross-coupling contour error compensation adjustment motion control card, driver, servo motor module and position feedback detection module. The numerically controlled PC includes a numerically controlled PC, a display and a PCI interface chip; one end is connected to the display to realize man-machine dialogue, and the other end is connected to the curve cross-coupling contour error compensation and adjustment motion control card through the PCI interface chip to realize the curve cross-coupling contour error compensation.

[0094] The described curve cross-coupling contour error compensation adjustment motion control card includes: the curve cross-coupling contour error compensation adjustment motion control card, PCI9025 chip, CPLD, communication module, I / O interface circuit module and curve cross-coupling c...

Embodiment 2

[0163] The experimental effect that the present invention carries out:

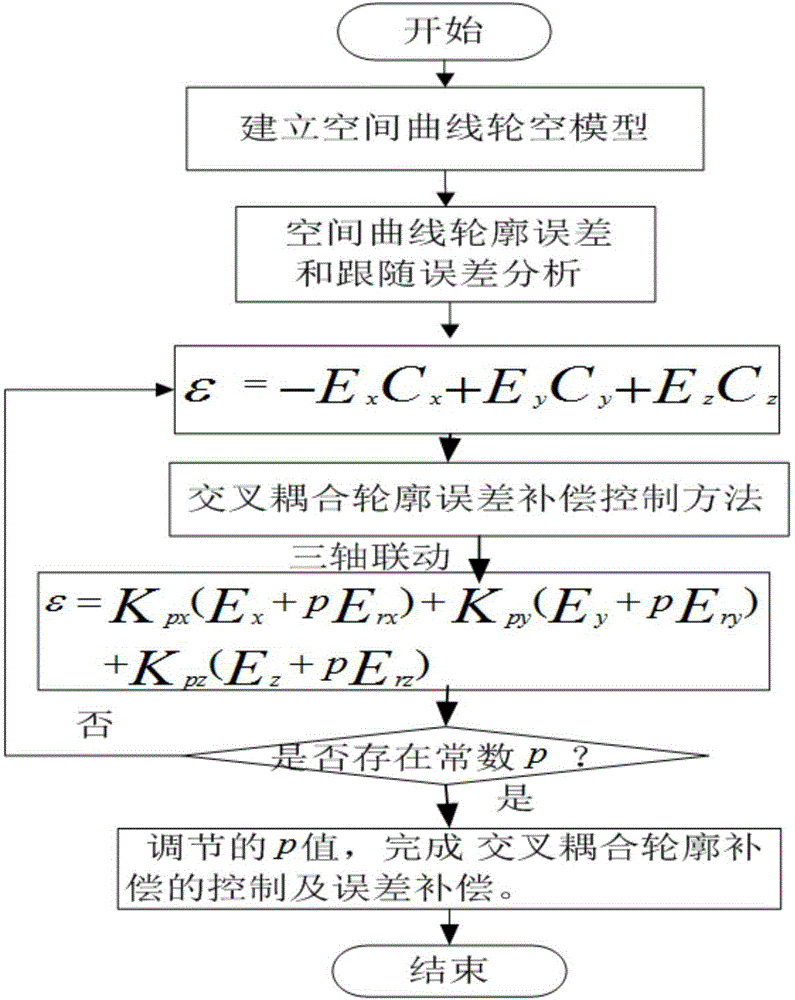

[0164] In order to verify the correctness and feasibility of the cross-coupling error compensation algorithm of CNC multi-axis linkage machine tools, a high-end three-axis linkage CNC machine tool is built to analyze error compensation. The experimental platform adopts an open CNC system, which can establish error models and real-time online error compensation, the experimental process such as Figure 8 As shown, the specific steps are:

[0165] Step1: Determine the following error of the curve according to the contour error of the curve;

[0166] ε=-E x C x +E y C y +E z C z ;

[0167] Step2: Determine the scheme of curve cross-coupling error compensation;

[0168] That is, the algorithm of curve cross-coupling error compensation;

[0169] ε=K px (E x +pE rx )+K py (E y +pE ry )+K pz (E z +pE rz );

[0170] Step3: The method of decoupling;

[0171] (1), x / y axis decoupling;

[0172]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com