A Control System of Flue Gas Denitrification Based on Mathematical Model

A mathematical model and control system technology, applied in general control systems, control/regulation systems, adaptive control, etc., can solve the problem that denitration control cannot be predicted in advance and accurately control the amount of ammonia injection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

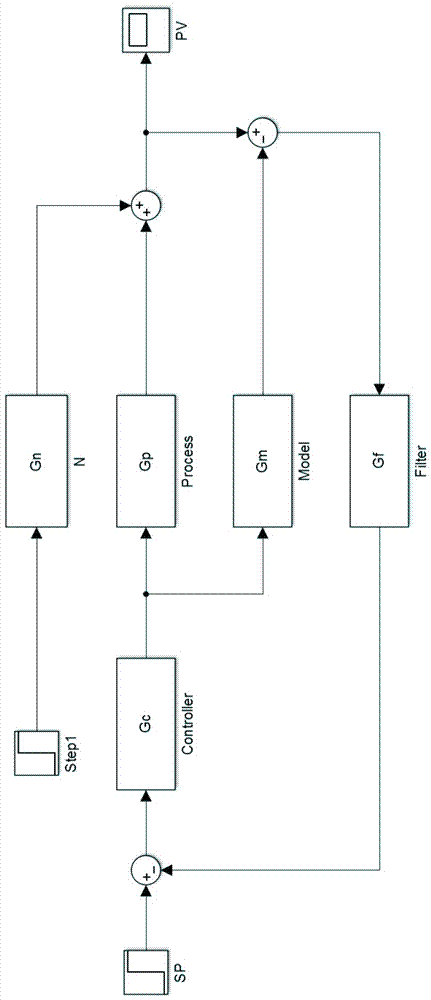

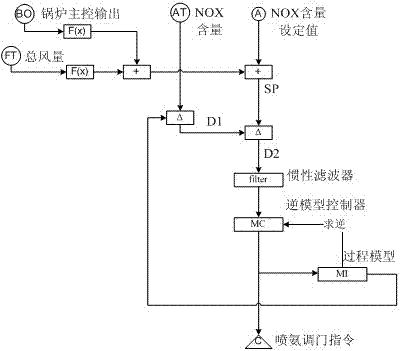

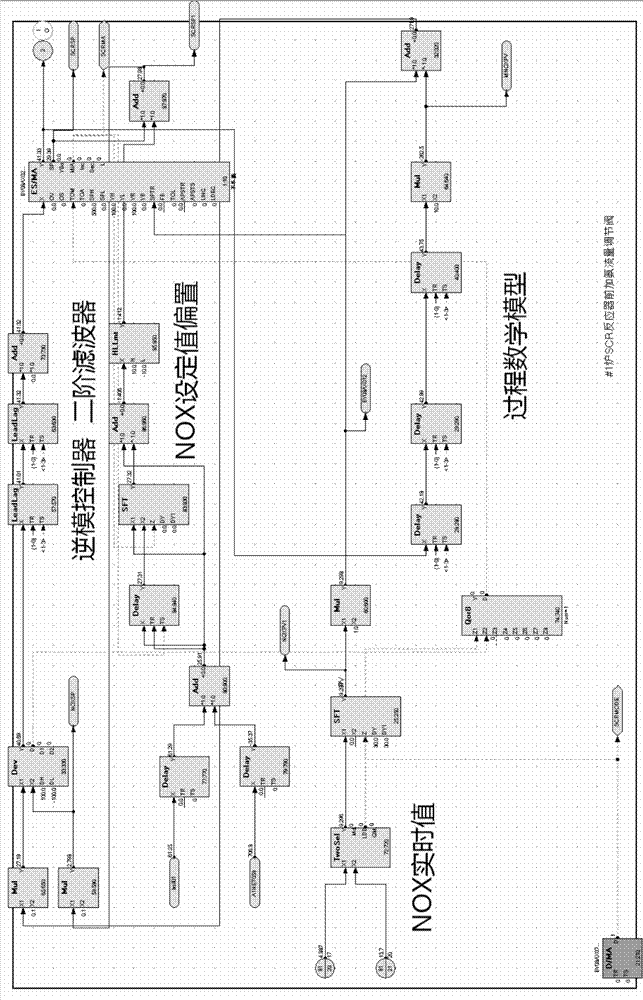

[0024] Below, refer to the attached figure 1 , attached figure 2 And attached image 3 , describe in detail as follows in conjunction with embodiment:

[0025] figure 1 , its closed-loop transfer function is: , where y pv (s) is the system output state, r sp (s) is the system setting, n(s) is the system disturbance, when the filter G f =1, it is assumed that the process link G p , G m and G c are stable, even if G p ≠G m , as long as the controller gain G c (0) and the model gain G m (0) are reciprocals of each other, then control deviation: , , indicating that no matter there is any deviation or disturbance, the system can still eliminate the static deviation after responding to the input deviation and disturbance, and realize the tracking of PV to SP. Therefore, the process mathematical model can be approximated to the on-site control law. Its control process is as follows:

[0026] 1. The SP is input by the operator according to the demand;

[0027] 2....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com