Coordinate type positioning device of shell-and-tube heat exchanger cleaning facility

A technology for tube heat exchangers and cleaning equipment, which is applied in the direction of cleaning heat transfer devices, lighting and heating equipment, etc., can solve the problems of low efficiency, high labor intensity, unsatisfactory cleaning effect, etc., and achieve accurate positioning and low labor intensity. , ideal cleaning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

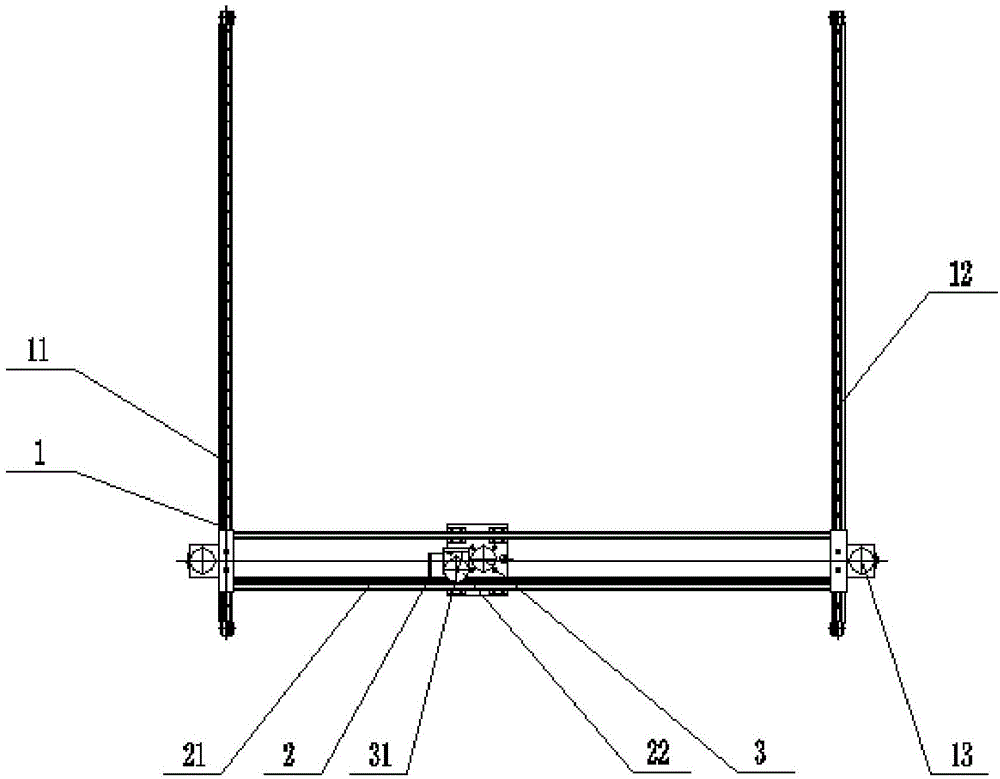

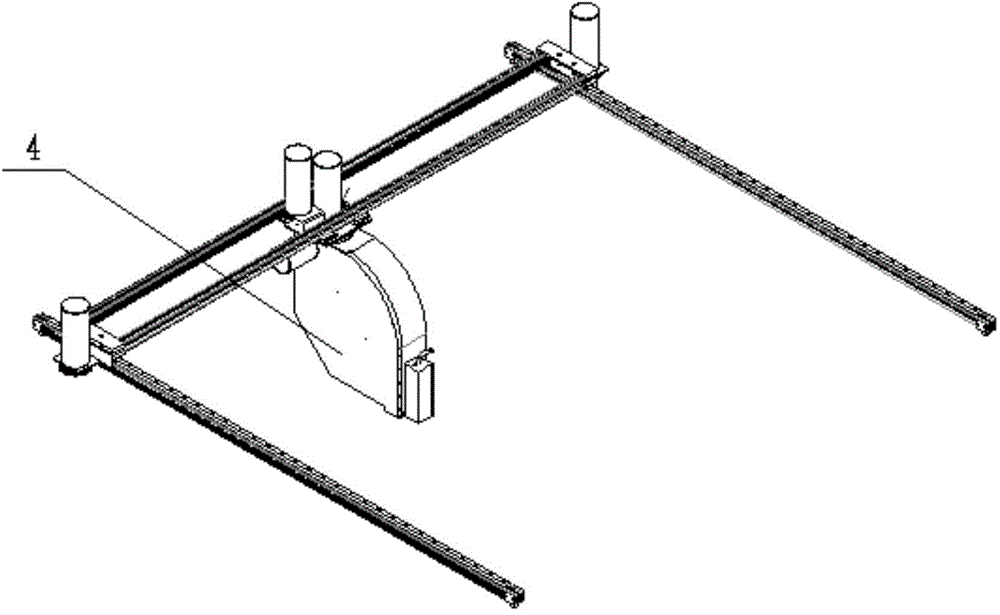

[0016] Such as Figure 1 to Figure 2 As shown, a coordinate positioning device in the tube heat exchanger cleaning equipment of the present invention includes a horizontal moving mechanism 2, a vertical moving mechanism 1 and a self-rotating mechanism 3, and the horizontal moving mechanism 2 includes a horizontal The guide rail 21 is provided with a horizontal movement drive mechanism 22 that is coupled to the horizontal guide rail 21 in the form of a rack and pinion; the horizontal movement drive mechanism 22 is fixedly connected to the self-rotation mechanism 3 through a sliding mounting base 31; Described vertical direction moving mechanism 1 comprises the first vertical guide rail 11 and the second vertical guide rail 12 that are symmetrically arranged on the two ends of horizontal guide rail 21; Mechanisms 2 are arranged perpendicular to each other; the two ends of the horizontal guide rail 21 are fixedly connected with a vertical movement drive mechanism 13; The racks a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com