Cereal sorting device with drying effect

A sorting device and grain technology, applied in drying, drying machine, solid separation, etc., can solve the problems of no drying effect, time-consuming and laborious, etc., and achieve good sorting effect, convenient use, improved effect and work efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

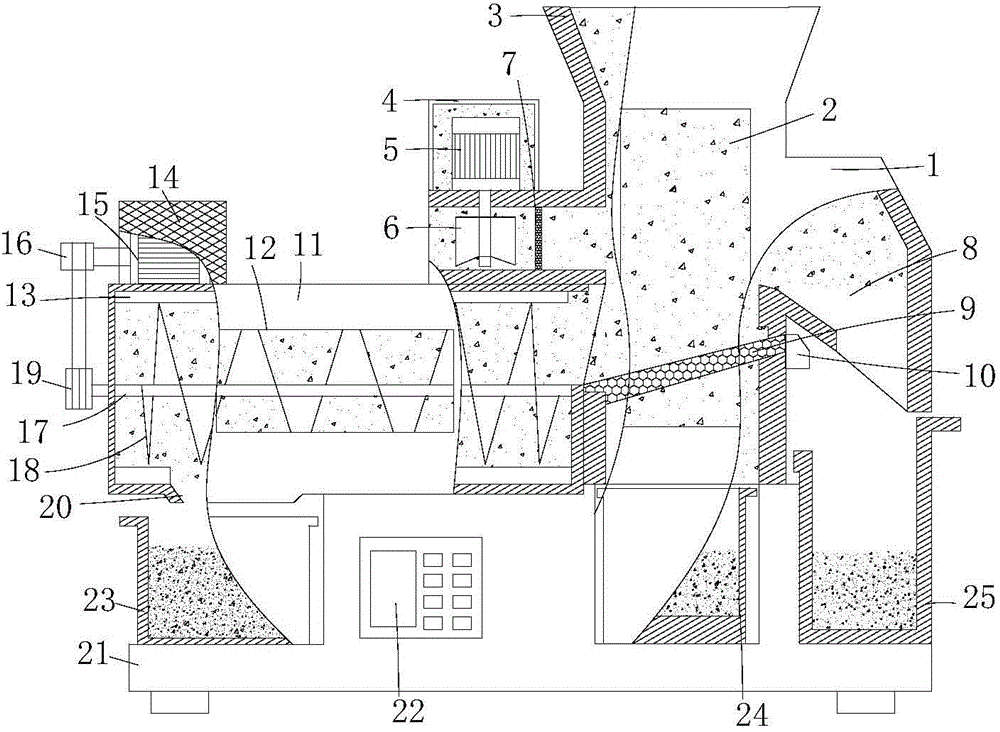

[0012] The present invention will be further described below in conjunction with accompanying drawing:

[0013] like figure 1 As shown, a grain sorting device with a drying effect includes a material cylinder 1 and a drying cylinder body 11. The front of the material cylinder 1 is provided with an observation window 2, and the top of the material cylinder 1 is provided with a feeding table 3. The material cylinder The top left side of 1 is provided with a protective cover 4, the inner cavity of the protective cover 4 is provided with an electric motor 5, and the inner cavity of the material barrel 1 is respectively provided with a fan blade 6 and a heating screen 7 from left to right, and the setting of the fan blade 6 It can generate continuous wind and convert it into hot air through the heating screen 7 to carry out primary sorting and drying treatment on the grain, and quickly and effectively reduce the sundries and moisture in the grain. The right side of the barrel 1 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com