Carbon fiber composite material axial flow fan impeller

A composite material, axial flow fan technology, used in liquid fuel engines, mechanical equipment, machines/engines, etc., can solve problems such as different functions, different blade forms and manufacturing processes, and achieve reduced operating energy consumption and corrosion resistance. Improved performance and reduced weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

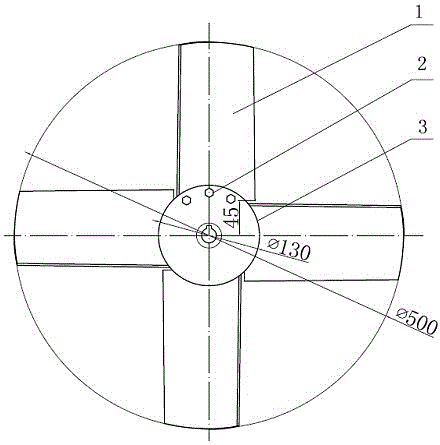

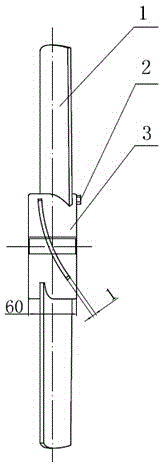

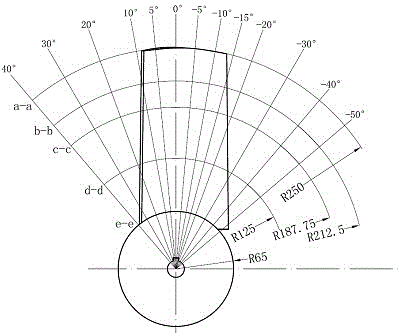

[0027] Such as figure 1 , figure 2 As shown, the carbon fiber composite material impeller structure of the present invention includes an impeller hub 3 , blades 1 and screws 2 . Two or more carbon fiber composite material blades 1 installed on the outer surface of the cylindrical metal impeller hub 3, the connection between the carbon fiber composite material blades and the metal impeller hub 3 can be connected by screws 2, or can be connected by a threaded pressing device and the screws. Combined connection; the cylindrical metal impeller hub 1 is installed on the output shaft of the motor through its central hole, the thickness of the impeller hub is 60 mm, the impeller rotates at a high speed driven by the motor, and pushes the air to enter from one end of the impeller rotating central shaft, and from the impeller The other end of the rotating cen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com