Hollow large-diameter excavated foundation and manufacturing method thereof

A manufacturing method and large-diameter technology, which can be used in basic structural engineering, construction, etc., can solve the problems of weakening economy and environmental protection, and increasing the diameter and burial depth of undisturbed soil excavation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments, but these embodiments should not be construed as limiting the present invention.

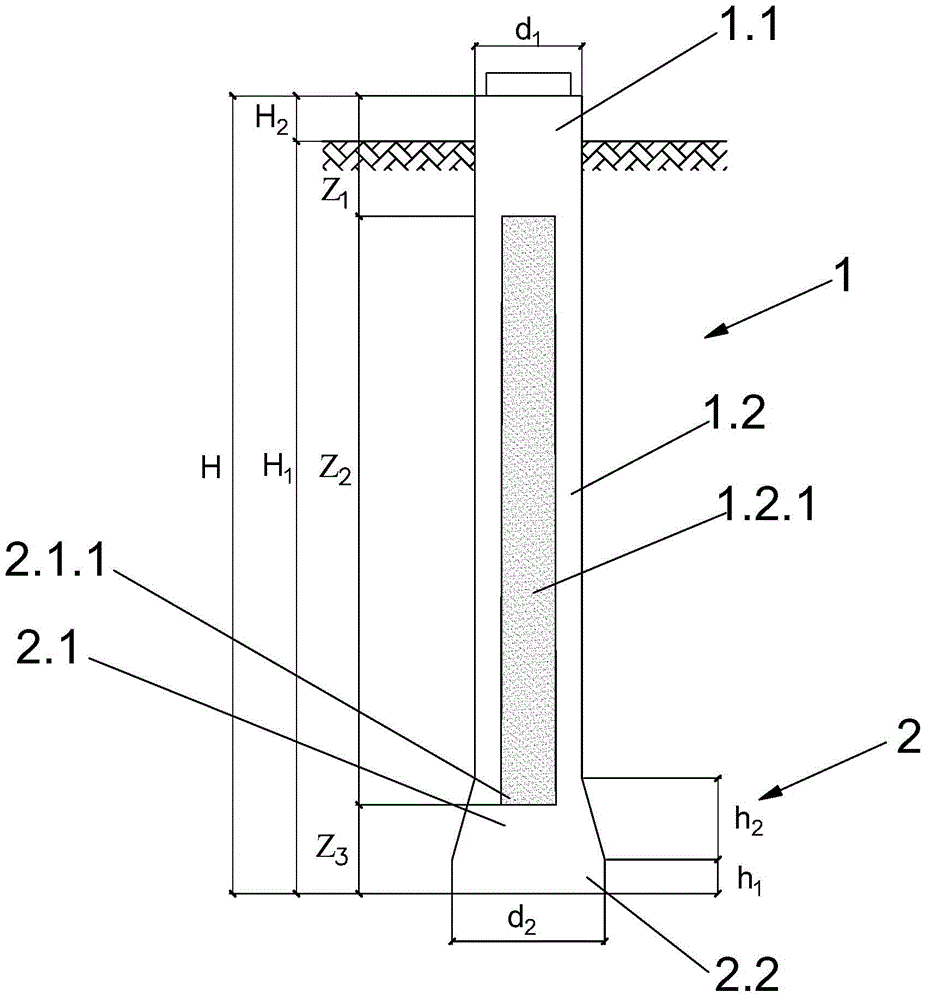

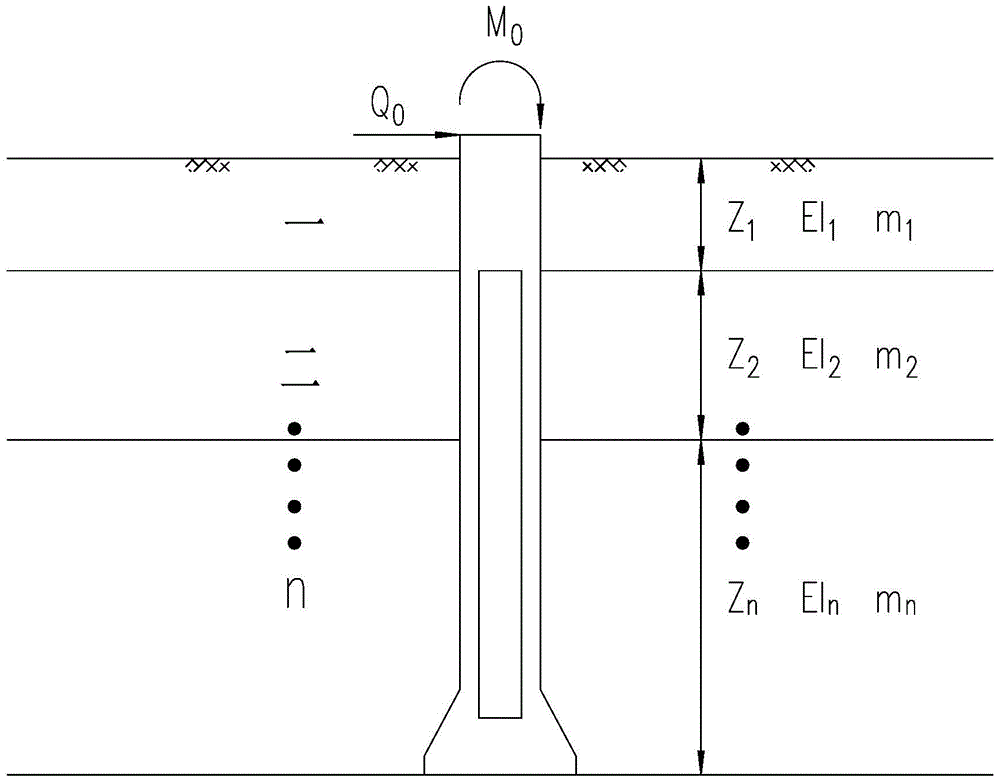

[0023] see figure 1 , the hollow large-diameter excavated foundation of the present invention includes a foundation main column 1 and a foundation wide bottom 2 sequentially connected from top to bottom; the foundation main column 1 includes a foundation outcrop 1.1 and a foundation buried depth section 1.2, and the foundation outcrop 1.1 Connected with the upper transmission tower steel truss (not shown in the figure), the foundation buried depth section 1.2 is provided with a main column cavity 1.2.1; The bottom cylinder 2.2 at the bottom of the round table 2.1, the top diameter of the round table 2.1 is equal to the bottom diameter of the foundation main column 1, the bottom diameter of the round table 2.1 is equal to the diameter of the end face of the bottom ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com