Novel road body structure

A new type of road body and new technology, applied to roads, roads, pavement details, etc., can solve problems such as unsatisfactory snow melting and deicing effects, low intelligence, and damage to road performance, so as to reduce costs and construction difficulties, improve efficiency, The effect of reducing requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

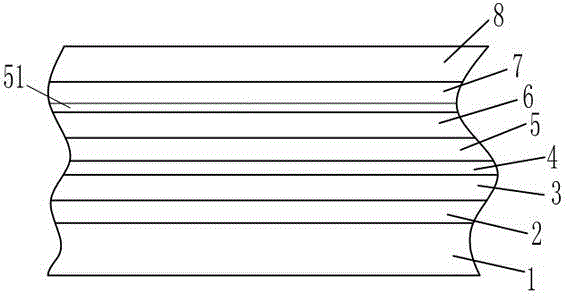

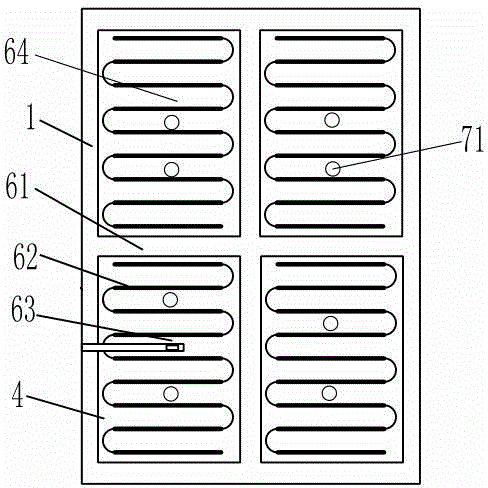

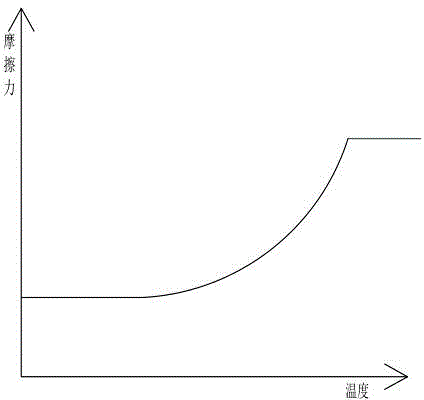

[0042] A new type of road body structure, including a moisture-proof layer 2 laid on the leveled and cleaned road base 1 from bottom to top, a thermal insulation layer 3 to prevent heat from being transmitted and lost downwards, a heating cable layer 6, and fixing and protecting the heating cable Layered pavement cushion 7 and pavement layer 8, the heating cable layer includes a plurality of evenly distributed heating areas, and several heating cables 62 arranged in parallel are connected in parallel on the heating areas, and a uniform heat is formed between adjacent heating cables. There is a friction-increasing gap 64, a reinforced fixed gap 61 is left between adjacent heating areas, and a temperature-sensing probe is arranged between at least one pair of adjacent heating cables in each heating area, and a uniform gap is left between the temperature-sensing probe and the heating cable. Thermal gap 63, a heat dissipation layer 5 for evenly diffusing the heat emitted by the hea...

Embodiment 2

[0048] The difference from the above embodiment is that the heat insulation layer and the reflective layer are glued and fixed, and there is a layer between the heating cable layer and the pavement cushion layer to prevent the heating cable in the heating cable layer from arching or The twisted mesh presses against the layer 51 . The reflective layer 4 is an aluminum foil layer, and the heat dissipation layer 5 is a metal mesh layer or a metal plate layer. The application selects a metal mesh layer, and the reflective layer or reflective layer and heat insulation layer or reflective layer, heat Reinforcement fixing holes 71 are provided for infiltrating into the pavement cushion material to form the reinforcement fixing columns of the anti-staggering layer. The thickness of the pavement cushion layer 7 is 5 cm, and the distance from the edge of the heating cable layer to the edge of the pavement base layer is 12 cm.

[0049] The metal mesh layer is also connected with a groun...

Embodiment 3

[0051] The difference from the above embodiment is that the thickness of the pavement cushion layer 7 is 3 cm, and the distance from the edge of the heating cable layer to the edge of the pavement base layer is 10 cm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com