A kind of high-strength low-temperature resistant steel and its heat treatment process

A low-temperature-resistant, high-strength technology, applied in the fields of high-strength low-temperature resistant steel and its heat treatment process, high-strength low-Ni series ferritic low-temperature resistant steel and its heat treatment process, can solve the problem of lack of low-temperature strong-toughness composite structural steel, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0072] The formula of high strength and low temperature resistant steel material is as follows: Ni: 6.85-7.05%; C: 0.045-0.060%; Si: 0.05-0.08%; Mn: 0.69-5.00%; Cr: 0.3-0.4%; Mo: 0.05-0.4% ; Cu: 0.02-0.3%; Al: 0.036-0.040%; P: ≤0.009%; S: ≤0.002%; N: 0.004-0.005%; O: 0.0005-0.002%; For Fe.

[0073] The elemental components in the above formula are mixed according to the ratio and then smelted, and then the slab is continuously cast into an ingot, which is air-cooled after multi-step hot rolling, and the thickness of the ingot is 240mm. Among them, the multi-step hot rolling conditions are: continuous temperature of 1050, 980, 850, 830, 810, 780, 770, and 750°C respectively, and the reduction rates are 29.17%, 29.41%, 25%, 22.22%, and 21.43%. , 20%, 20%, 21.88%, the holding time is 170, 120, 90, 70, 50, 40, 32, 25 minutes respectively. The specific data of multi-step hot rolling is shown in Table 1, and the specific steps are shown in figure 1 . The hot-rolled ingot was ins...

Embodiment 2

[0076] The formula of high strength and low temperature resistant steel material is as follows: Ni: 2.0-5.75%; C: 0.02-0.1%; Si: 0.02%-0.1%; Mn: 4.75-8.00%; Cr: 0.3-0.4%; Mo: 0.15-0.60 %; Cu: 0.02-0.3%; Al: 0.044-0.048%; P: ≤0.009%; S: ≤0.002%; N: 0.004-0.005%; The amount is Fe.

[0077] The elemental components in the above formula are mixed according to the ratio and then smelted, and then the slab is continuously cast into an ingot, which is air-cooled after multi-step hot rolling, and the thickness of the ingot is 240mm. Among them, the multi-step hot rolling conditions are: continuous temperature of 1050, 980, 850, 830, 810, 780, 770, and 750°C respectively, and the reduction rates are 29.17%, 29.41%, 25%, 22.22%, and 21.43%. , 20%, 20%, 21.88%, the holding time is 170, 120, 90, 70, 50, 40, 32, 25 minutes respectively. The specific data of multi-step hot rolling is shown in Table 1, and the specific steps are shown in figure 1 . The hot-rolled ingot was inspected unde...

Embodiment 3

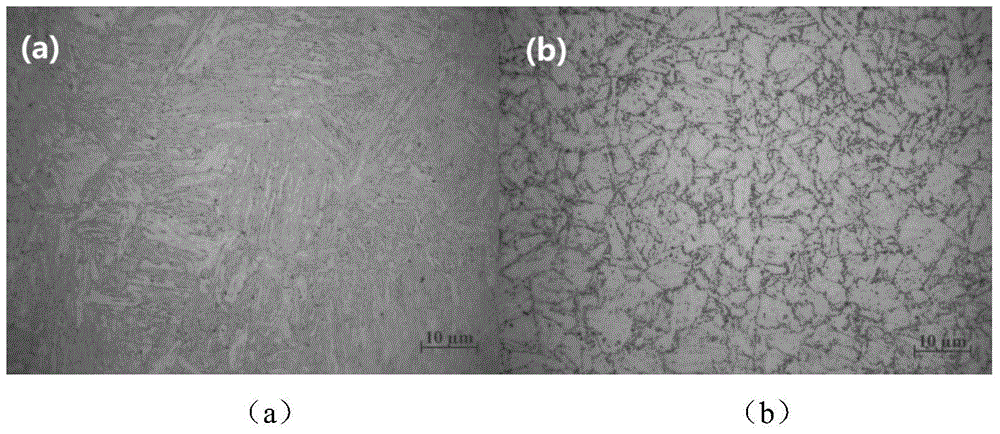

[0082] The high-strength and low-temperature-resistant steel material samples 1-2# in Example 1-2 were respectively observed with an optical microscope for structure and retained austenite. For specific results, see figure 2 a, 2b, 3a, 3b.

[0083] Depend on figure 2 a, 2b, 3a, and 3b, it can be seen that the structure of the sample in the hot-rolled state is relatively disordered, the deformation is severe, and there are many dislocations and defects. The toughness of this structure is bound to be poor, but after QLT treatment, the structure All are tempered martensite + acicular ferrite + a small amount of austenite, the deformation caused by hot rolling is eliminated by heat treatment, and the structure is also refined.

[0084] At the same time, the retained austenite content measured by magnetic field is shown in Table 2 for specific data. It can be seen from Table 2 that the austenite content of the steel after QLT heat treatment has increased significantly, thereby ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com