A kind of low surface energy self-polishing type polyurethane marine antifouling coating and preparation method thereof

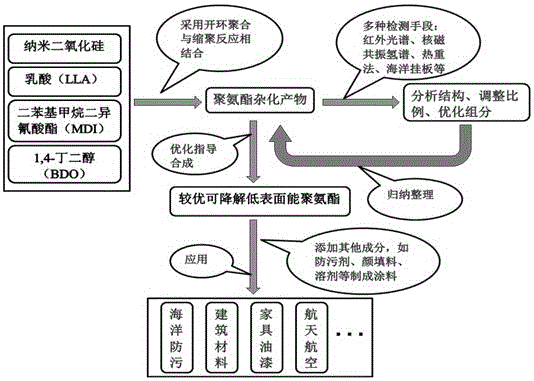

A technology of polyurethane coatings and low surface energy, applied in polyurea/polyurethane coatings, anti-fouling/underwater coatings, coatings, etc., can solve problems such as weak polishing ability, low surface energy, degradability, and unusability, and achieve The price is environmentally friendly, no pollution, good self-polishing ability, and short reaction time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

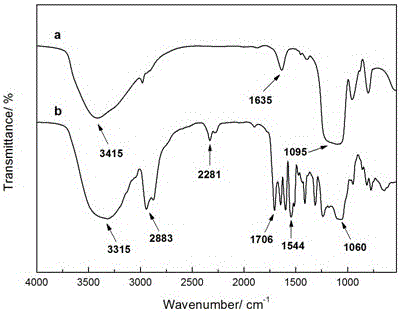

Method used

Image

Examples

Embodiment 1

[0030] A kind of low surface energy self-polishing type polyurethane marine antifouling coating, concrete steps and method are:

[0031] (1) Reagent purification:

[0032] 1) Drying of nano-silica: Take 4 g of nano-silica in a beaker, place it in an oven, and control the temperature at about 70°C-80°C (not exceeding 110°C, which will cause the hydroxyl groups on the surface of nano-silica, etc. group falling off), dry for 12h.

[0033] 2) Dewatering of tetrahydrofuran / n-hexane: measure a certain volume of tetrahydrofuran / n-hexane in a 500 mL round bottom flask, take an appropriate amount of metallic sodium and chop it into sodium particles, add it to tetrahydrofuran / n-hexane, and use a collector type constant temperature heating The magnetic stirrer was condensed and refluxed at about 100 ℃ for 3-7 days, and the indicator (benzophenone) was added in time until the solution turned blue (or purple), and the distillate was collected at about 67 ℃, and the water removal was compl...

Embodiment 2

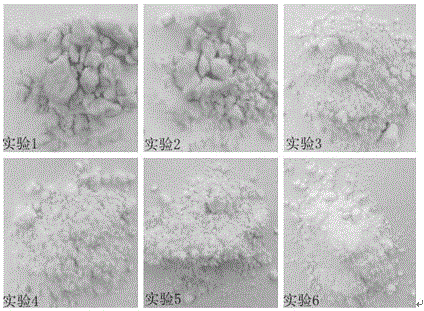

[0038] Embodiment 2: adding SiO 2 The amount of PLA / PLA was 0.3 g, and other steps and methods were the same as in Example 1 to obtain product 2. The experiment found that the product 2 was slightly less agglomerated than in Example 1, the particles became smaller, and the color was taupe.

Embodiment 3

[0039] Embodiment 3: adding SiO 2 The amount of PLA / PLA was 0.5 g, and other steps and methods were the same as in Example 1 to obtain product 3. The experiment found that the product 3 was slightly less agglomerated than in Example 2, the particles became smaller, and the color was gray.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com