A non-contact glass micro-nano structure processing method

A processing method, non-contact technology, applied in the field of preparing micro-nano structures, can solve the problems of harsh etching line width, expensive patterning, etc., and achieve the effect of simplifying the process cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

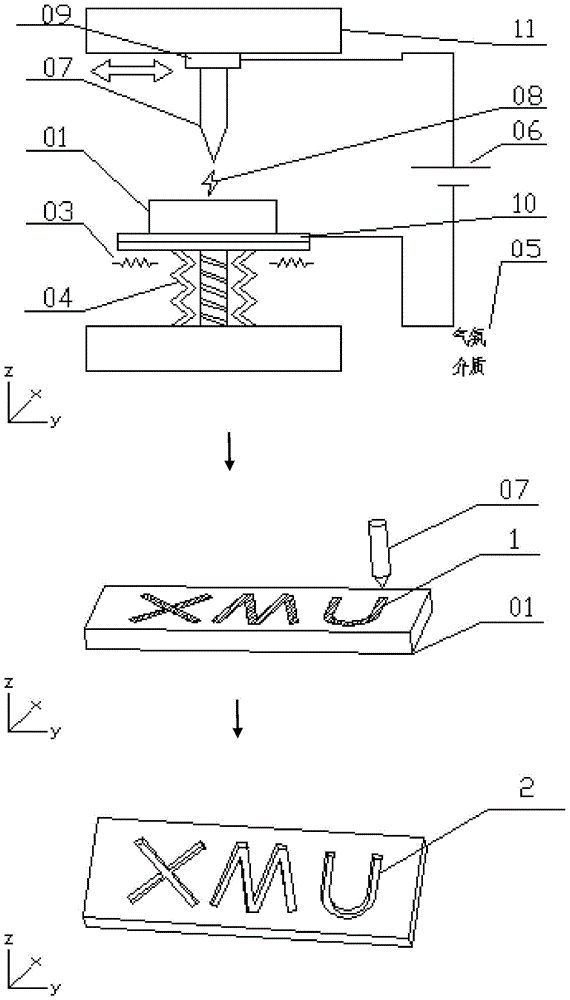

[0018] see figure 1 , the specific steps of the embodiment of the present invention are given below:

[0019] Step 1: The glass sheet 01 is placed on the Z-axis mobile platform 04 and connected to the negative pole of the power supply 06; the conductive material 07 is made of semiconductor silicon material, processed into a needle-like shape by micro-nano etching technology, and the conductive material 07 is placed on the glass sheet 01 , fixed on the X-Y plane moving platform 11, and connected to the positive pole of the power supply 06; turn on the heating device 03 to heat the glass sheet 01 to between 250°C and 500°C; change the distance value between the glass sheet 01 and the conductive material 07 a; and adjust the voltage value of the power supply 06 to U to break down the atmosphere medium 05 and form an arc 08. Taking air as an example, the distance value a between the glass sheet 01 and the conductive material 07 and the voltage value U of the power supply 06 satis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com