Molding method of integral composite material reinforced cylinder, laying tool, curing mold and stringer positioning device

A composite material and positioning device technology, applied in the field of composite material molding, can solve the problems of low pass rate, damage, complicated operation, etc., and achieve the effect of solving the problem of demoulding, improving the pass rate and improving the precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

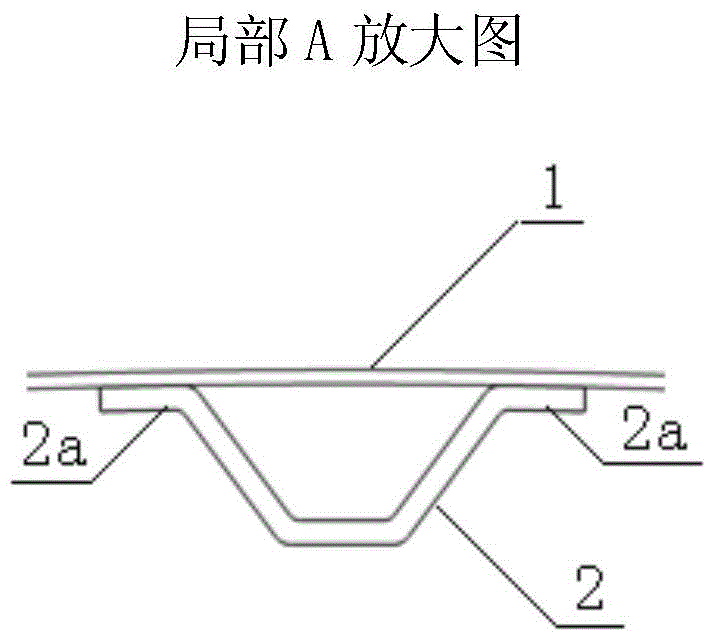

[0062] The structure of the overall composite material reinforced cylinder is as follows: it is composed of a cylindrical skin and 18 long stringers. The cross-sectional shape of the long stringers is hat-shaped. The inner cylindrical surfaces are bonded as a whole by adhesive film, and all the stringers are evenly distributed along the circumference; the outer diameter of the outer surface of the skin is 3m, the length of the skin is 5m, and the length of the stringers is equal to the length of the skin ;Firstly, the long stringer is laid on the mold and solidified, and the forming steps of the overall composite material reinforced cylinder are:

[0063] 1. Assemble the lay-up mold: connect one end of the central shaft on the support frame of the lay-up mold with the output shaft of the drive seat through a coupling, and install the other end of the central shaft on the support seat through a bearing;

[0064] 2. Adjust the movable mold: adjust the radial position of the mova...

Embodiment 2

[0083] The structure of the overall composite material reinforced cylinder is as follows: it is composed of a cylindrical skin and 36 long stringers. The inner cylindrical surfaces are bonded as a whole by adhesive film, and all the stringers are evenly distributed along the circumference; the outer diameter of the outer surface of the skin is 5m, the length of the skin is 10m, and the length of the stringers is equal to the length of the skin ;Firstly, the long stringer is laid on the mold and solidified, and the forming steps of the overall composite material reinforced cylinder are:

[0084] 1. Assemble the lay-up mold: connect one end of the central shaft on the support frame of the lay-up mold with the output shaft of the drive seat through a coupling, and install the other end of the central shaft on the support seat through a bearing;

[0085] 2. Adjust the movable mold: adjust the radial position of the movable mold on the laying mold, so that the skin of the movable m...

Embodiment 3

[0104] The structure of the overall composite material reinforced cylinder is as follows: it is composed of a cylindrical skin and 64 long stringers. The inner cylindrical surfaces of the skin are bonded as a whole by adhesive film, and all the long stringers are evenly distributed along the circumference; the maximum outer diameter of the outer surface of the skin is 7m, the length of the skin is 15m, and the length of the long stringers is equal to that of the skin length; first, the long stringer is paved and solidified on the mold, and it is characterized in that: the molding steps of the integral composite material reinforced cylinder are:

[0105] 1. Assemble the lay-up mold: connect one end of the central shaft on the support frame of the lay-up mold with the output shaft of the drive seat through a coupling, and install the other end of the central shaft on the support seat through a bearing;

[0106] 2. Adjust the movable mold: adjust the radial position of the movabl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com