Preparation method of nickel nanoparticles

A technology of nickel nanoparticles and nickel acetylacetonate, which is applied in the field of green and environmentally friendly synthesis of nickel nanoparticles, can solve problems such as ecological environment damage and environmental pollution, and achieve the effects of simple production process and uniform size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Example 1: Synthesis of nickel nanoparticles

[0024] Add 5ml olive oil and 0.4mmol nickel acetylacetonate to a 50ml three-necked flask, connect to the nitrogen protection of the Schilek system, and use a heating mantle to control the heating under the state of magnetic stirring, first at a rate of 10℃ per minute to heat up Keep it at 100℃ for 2 minutes, then increase the temperature to 120℃, react for 20 minutes to fully dissolve the nickel acetylacetonate; then increase the temperature to 280℃ at a heating rate of 20℃ per minute, and react for 15 minutes; then nitrogen protection Lower the temperature to 70~80℃, wash the sample with n-butanol and n-hexane 4 to 5 times (the ratio of reaction liquid to n-hexane and n-butanol is 1:1:2), and separate the product with a centrifuge to obtain a black powder , Disperse it in n-hexane for storage.

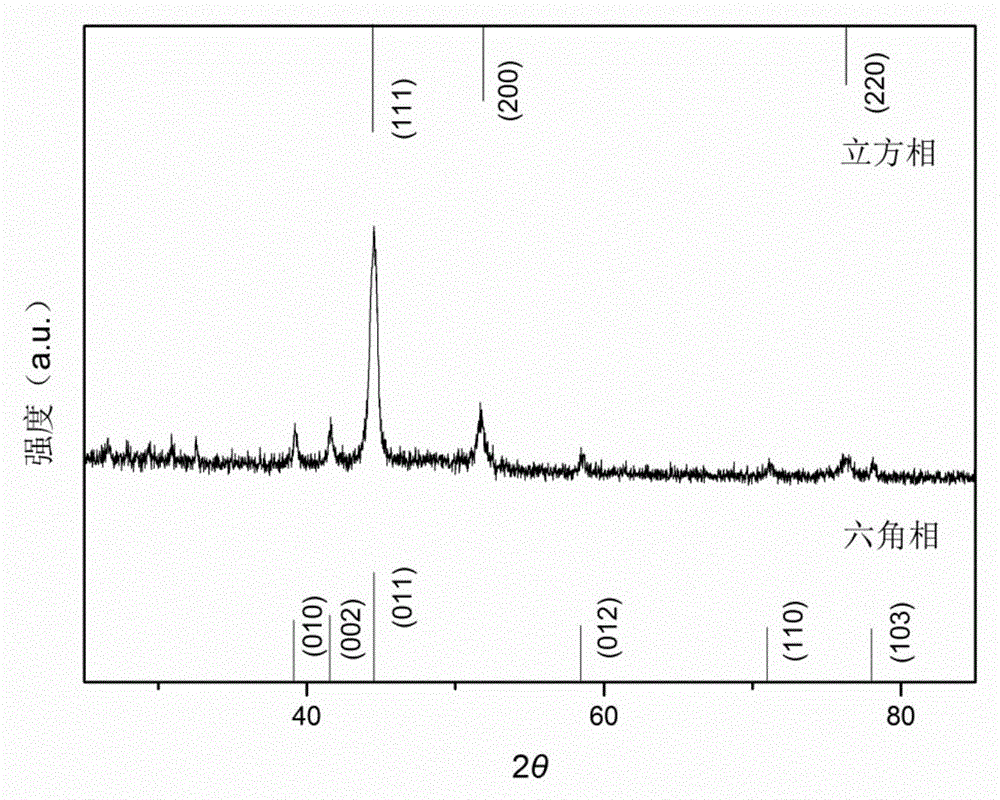

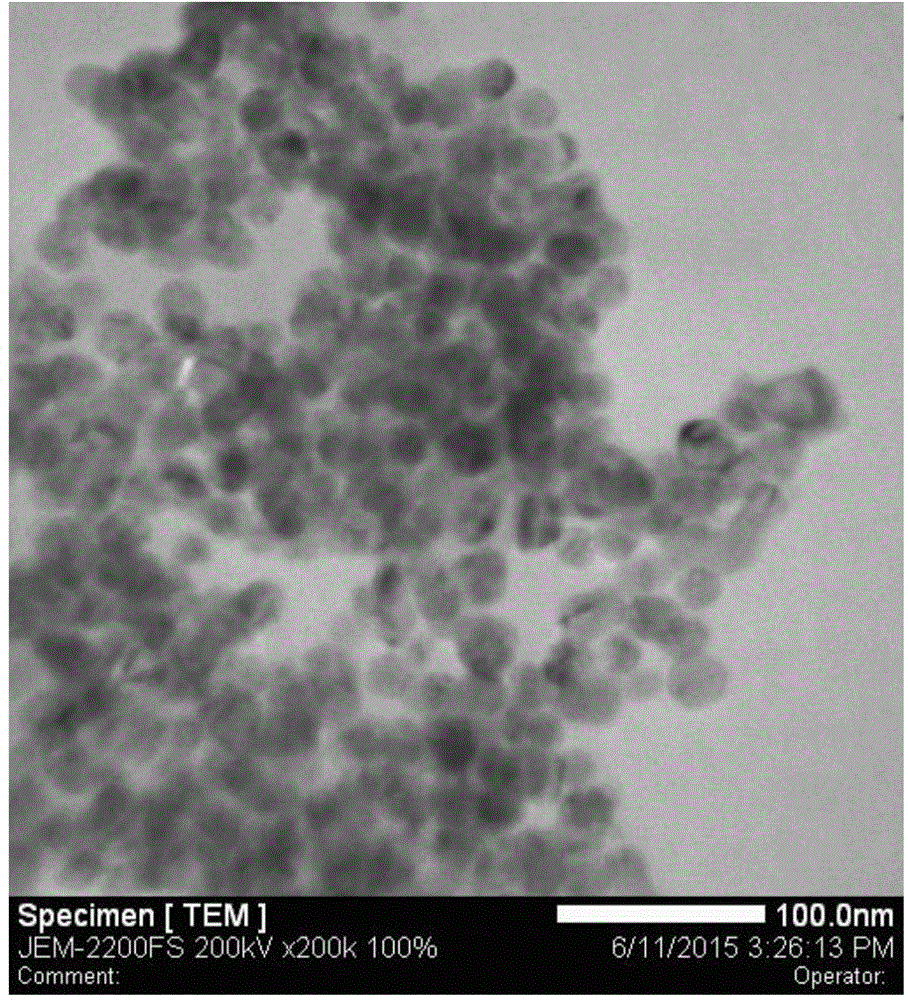

[0025] The XRD pattern of the sample prepared in this example is as follows figure 1 , See the TEM photo figure 2 ,by figure 1 The X...

Embodiment 2

[0026] Example 2: Synthesis of nickel nanoparticles by reducing the reaction time

[0027] Add 5ml olive oil and 0.4mmol nickel acetylacetonate to a 50ml three-necked flask, connect to the nitrogen protection of the Schilek system, and use a heating mantle to control the heating under the state of magnetic stirring, first at a rate of 10℃ per minute to heat up Keep it at 100℃ for 2 minutes, then increase the temperature to 120℃, react for 20 minutes to fully dissolve the nickel acetylacetonate; then increase the temperature to 280℃ at a heating rate of 20℃ per minute, and react for 10 minutes; then nitrogen protection Lower the temperature to 70~80℃, wash the sample with n-butanol and n-hexane 4 to 5 times (the ratio of reaction liquid to n-hexane and n-butanol is 1:1:2), and separate the product with a centrifuge to obtain a black powder , Disperse it in n-hexane for storage.

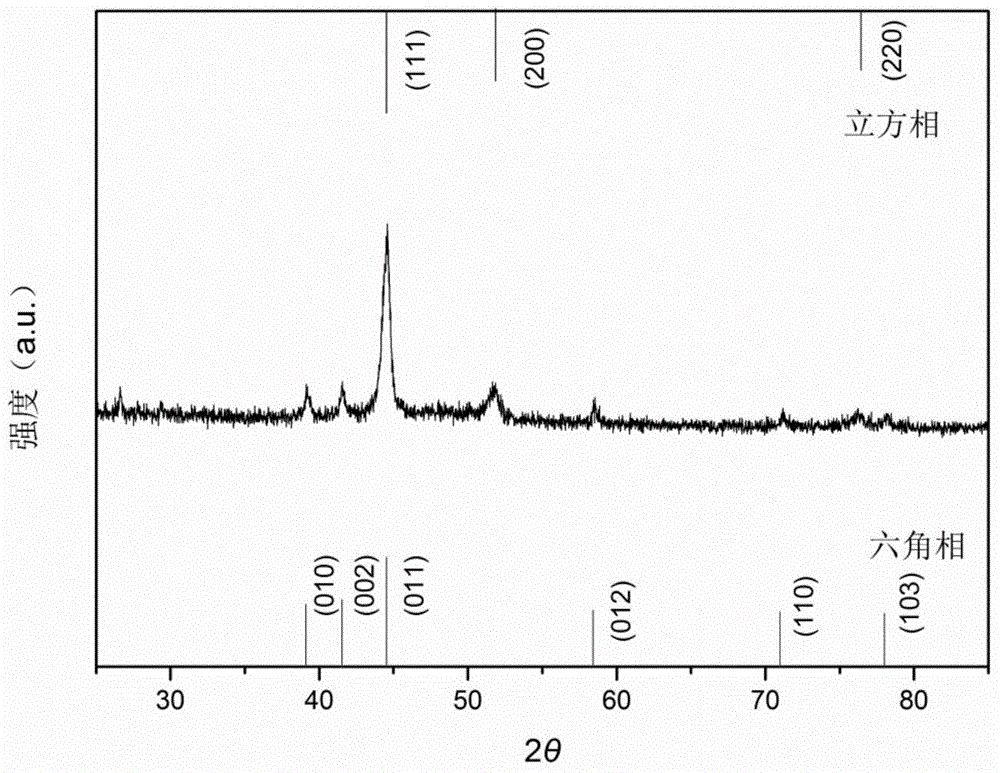

[0028] The XRD pattern of the sample prepared in this example is as follows image 3 The product of Exa...

Embodiment 3

[0029] Example 3: Synthesis of nickel nanoparticles by increasing the reaction time

[0030] Add 5ml olive oil and 0.4mmol nickel acetylacetonate to a 50ml three-necked flask, connect to the nitrogen protection of the Schilek system, and use a heating mantle to control the heating under the state of magnetic stirring, first at a rate of 10℃ per minute to heat up Keep it at 100℃ for 2 minutes, then increase the temperature to 120℃, react for 20 minutes to fully dissolve the nickel acetylacetonate; then increase the temperature to 280℃ at a heating rate of 20℃ per minute, and react for 30 minutes; then nitrogen protection Lower the temperature to 70~80℃, wash the sample with n-butanol and n-hexane 4 to 5 times (the ratio of reaction liquid to n-hexane and n-butanol is 1:1:2), and separate the product with a centrifuge to obtain a black powder , Disperse it in n-hexane for storage.

[0031] The XRD pattern of the sample prepared in this example is as follows Figure 4 The product of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com