Punching device based on laser positioning and board adjustment and method thereof

A laser positioning and punching device technology, which is applied in the field of sheet metal processing, can solve the problems of low punching accuracy, easy deformation of the plate, lack of support devices, etc., and achieve the effect of preventing overall deformation and avoiding external collision damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The specific implementation manner of the present invention will be described below in conjunction with the accompanying drawings.

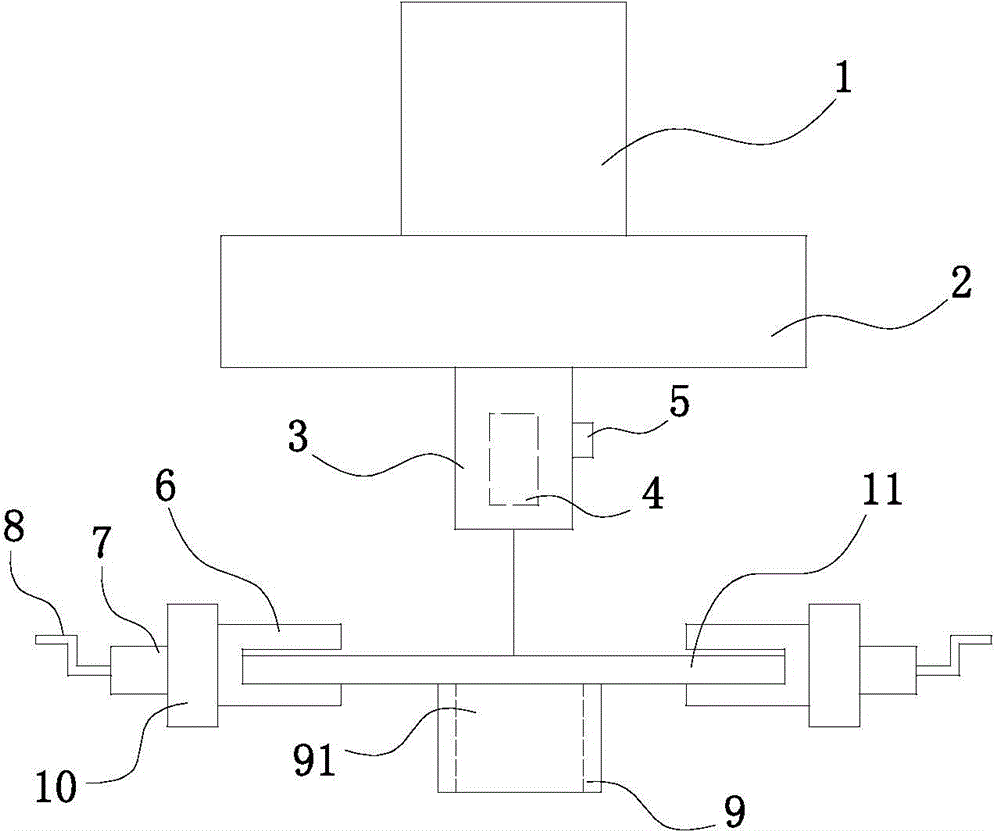

[0016] See figure 1 , the present invention includes a punching driving device 1, an upper template 2 and a punching head 3, and also includes a clamping device and a support block 9 positioned below the punching head 3, the clamping device includes a symmetrically arranged clamping block 6, clamping The holding block 6 is installed on the bracket 10 by means of the screw shaft 7, the outer end of the screw shaft 7 is connected with the handle 8, and the supporting block 9 has a punching groove 91; the laser head 4 is installed in the punching head 3 by means of the set screw 5.

[0017] The punching head 3 and the support block 9 of the present invention are all fixed on the frame (not shown). position, then start the laser head 4, the laser beam of the laser head 4 is irradiated on the workpiece 11, and a small mark is made, and the cla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com