Co-platform flotation column and flotation machine combined separating technology and device

A flotation column and flotation machine technology, applied in flotation, solid separation, etc., can solve problems such as low flotation precision, high loss of concentrate products, and waste of resources, so as to improve the economic benefits of enterprises and facilitate subsequent process transformation , The effect of continuous and stable feeding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

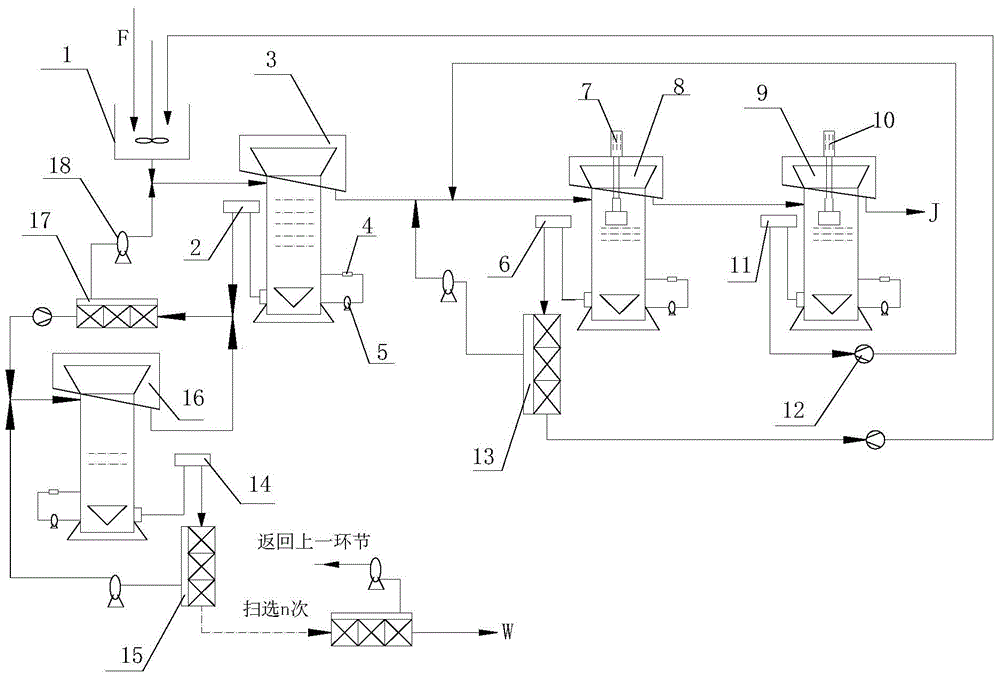

[0033] Embodiment 1: The combined mineral processing process: the raw ore and the medicament are stirred to form a slurry feed, after roughing by a rougher flotation column, two times of selection by a selection flotation column, and a pair of scavenging flotation machines and scavenging flotation columns The rougher tailings are swept multiple times, and the fine sweep flotation machine sweeps the fine I flotation column tailings to obtain the final concentrate and tailings;

[0034] Specific steps are as follows:

[0035] (1) According to the requirements of mineral types and sorting operations, add chemicals and raw ore F in the slurry mixing tank to mix and mix; the mass percentage concentration of the input material formed by stirring and mixing is 25%-45% according to the different types of selected minerals;

[0036] (2) The ore pulp formed by stirring flows into the rougher flotation column for roughing, and the rougher tailings are fed into the Sweep I flotation machi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com