Self-support transition metal selenide catalyst as well as preparation method and application thereof

A technology of transition metals and transition metal elements, applied in the field of self-supporting transition metal selenide catalysts and their preparation, can solve the problems of low catalytic activity and limited pH value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0028] The invention provides a preparation method of a self-supporting transition metal selenide catalyst, the method comprising:

[0029] Step 1: dissolving selenium powder in aqueous solution of sodium borohydride, or adding metal salts of transition metal elements to obtain a mixed solution;

[0030] Step 2: adding the transition metal conductive substrate to the mixed solution obtained in Step 1 for reaction to obtain a self-supporting transition metal selenide catalyst.

[0031] According to the present invention, the selenium powder is first dissolved in the sodium borohydride aqueous solution to obtain the sodium selenium hydride solution, preferably added under the condition of magnetic stirring, and the mass ratio of the described selenium powder and sodium borohydride is preferably (0.01~0.1 ): (0.02~0.1); or adding a metal salt of a transition metal element to obtain a mixed solution; the molar ratio of the selenium powder to the metal salt of a transition metal el...

Embodiment 1

[0042] Weigh 0.059 grams of selenium powder and dissolve it in 1.5 milliliters of distilled water containing 0.065 grams of sodium borohydride with magnetic stirring to prepare a sodium selenium hydride solution, transfer the solution to a 50 milliliter reaction axe, and add 1 × 3 cm of washing Put the reaction ax into a 140°C oven to react for 12 hours, wash the product with distilled water and ethanol and put it in a 60°C oven to dry to obtain a nickel mesh with nickel selenide nanowire arrays.

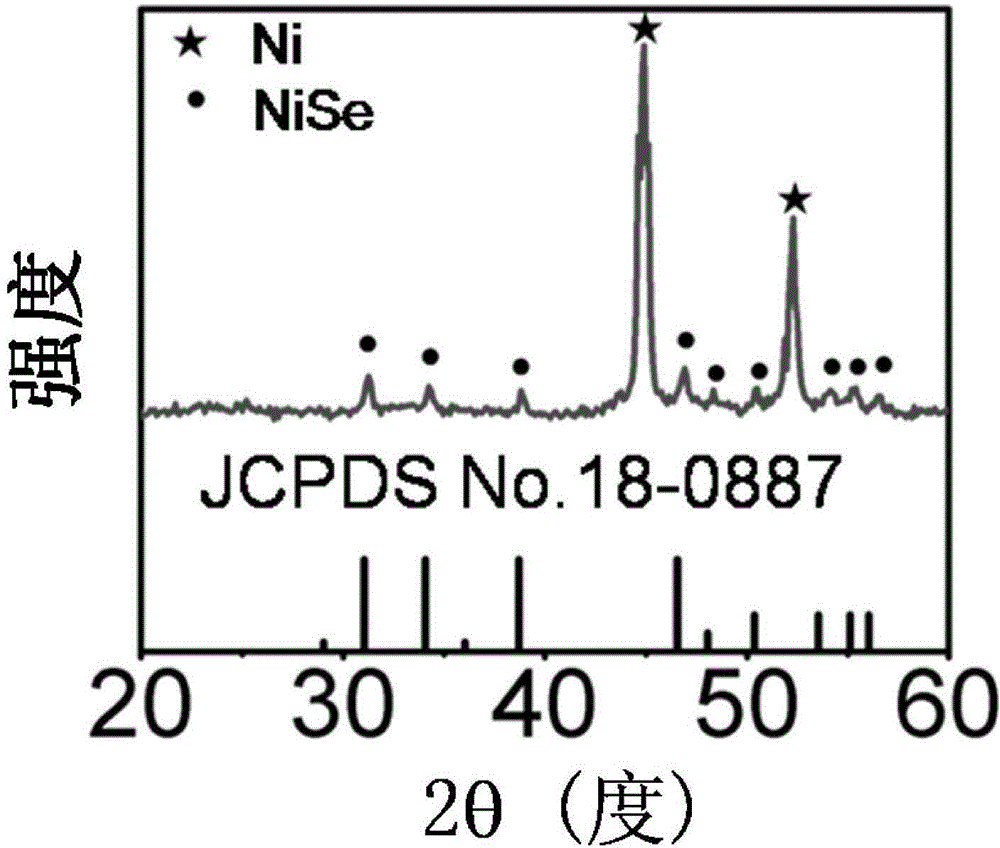

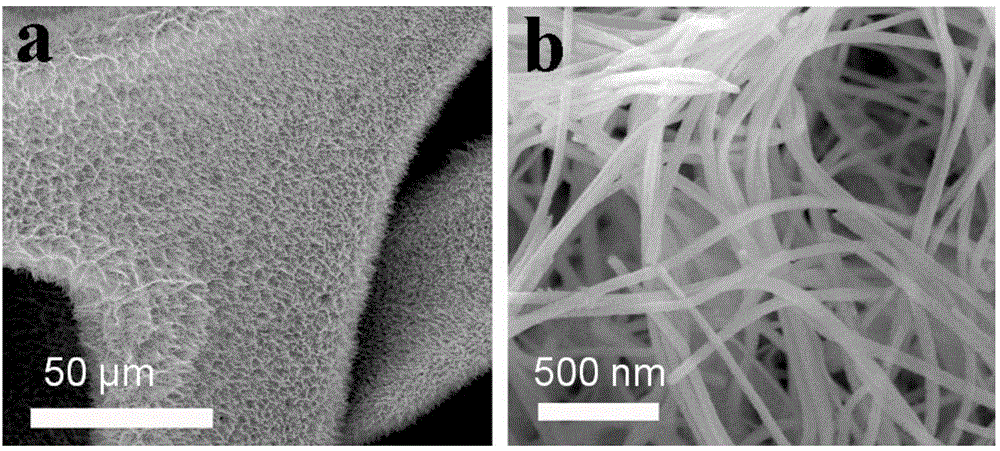

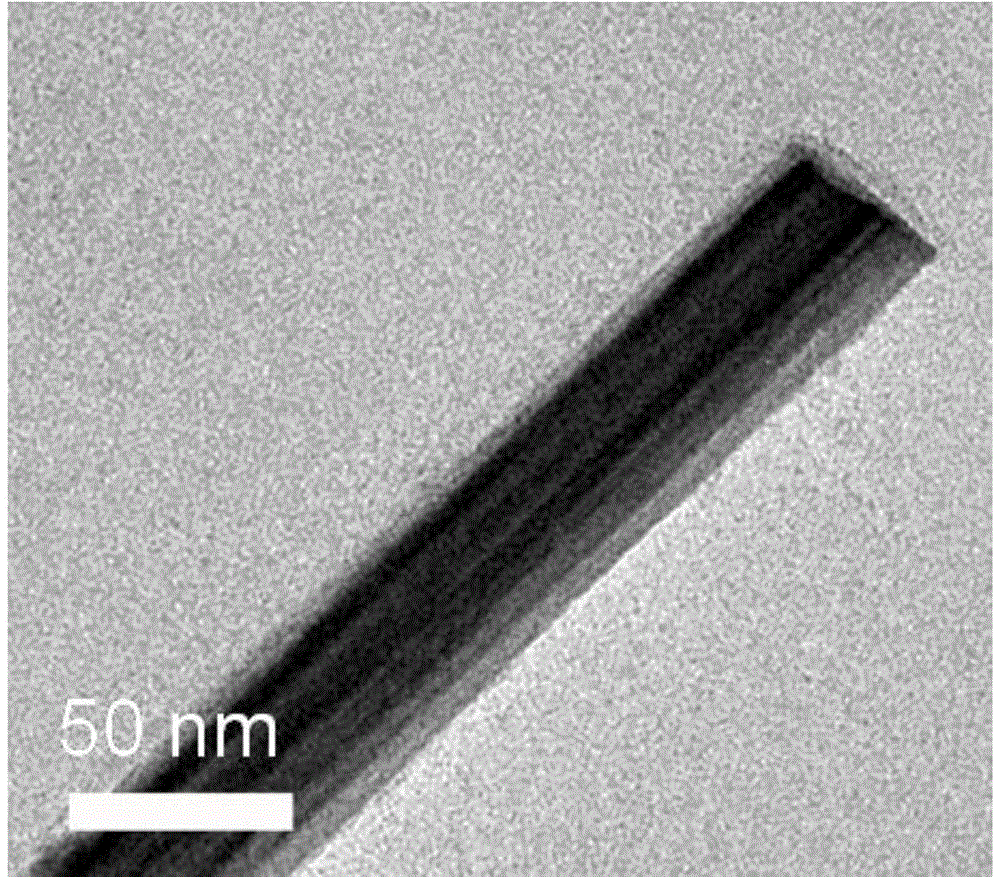

[0043] figure 1 It is the X-ray diffraction pattern of the nickel mesh with the nickel selenide nanowire array obtained in Example 1, which shows that the final product is nickel selenide. figure 2 It is the scanning electron micrograph of the nickel mesh with the nickel selenide nanowire array obtained in Example 1, wherein figure a is a scanning electron micrograph under a 50 μm scale, and figure b is a scanning electron micrograph under a 500nm scale, figure 2 It shows that th...

Embodiment 2

[0045] Weigh 0.059 grams of selenium powder and dissolve it in 1.5 milliliters of distilled water containing 0.065 grams of sodium borohydride with magnetic stirring to prepare a sodium selenium hydride solution, transfer the solution to a 50 milliliter reaction axe, and add 1 × 3 cm of washing Put the reaction ax into a 140°C oven to react for 12 hours, wash the product with distilled water and ethanol and put it into a 60°C oven to dry to obtain a nickel foil with nickel selenide nanowire arrays.

[0046] Figure 5 It is the scanning electron micrograph of the nickel foil with the nickel selenide nanowire array obtained in Example 2, wherein figure a is a scanning electron micrograph under a 5 μm scale, and figure b is a scanning electron micrograph under a 500nm scale, Figure 5 It shows that the nickel foil with nickel selenide nanowire arrays obtained in Example 2 has a diameter of 20-80 nanometers and a length of 1-6 microns. The nickel selenide nanowire array catalyst ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com