Hydrophilic antibacterial ultrafiltration membrane and preparation method for same

An ultrafiltration membrane and hydrophilic technology, which is applied in the field of hydrophilic antibacterial ultrafiltration membrane and its preparation, can solve the problems that the regeneration of nanoparticles has not been effectively solved, increase the application cost of filtration membranes, etc., and achieve lasting hydrophilicity Sexuality and antibacterial properties, saving resources, and improving the effect of hydrophilicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

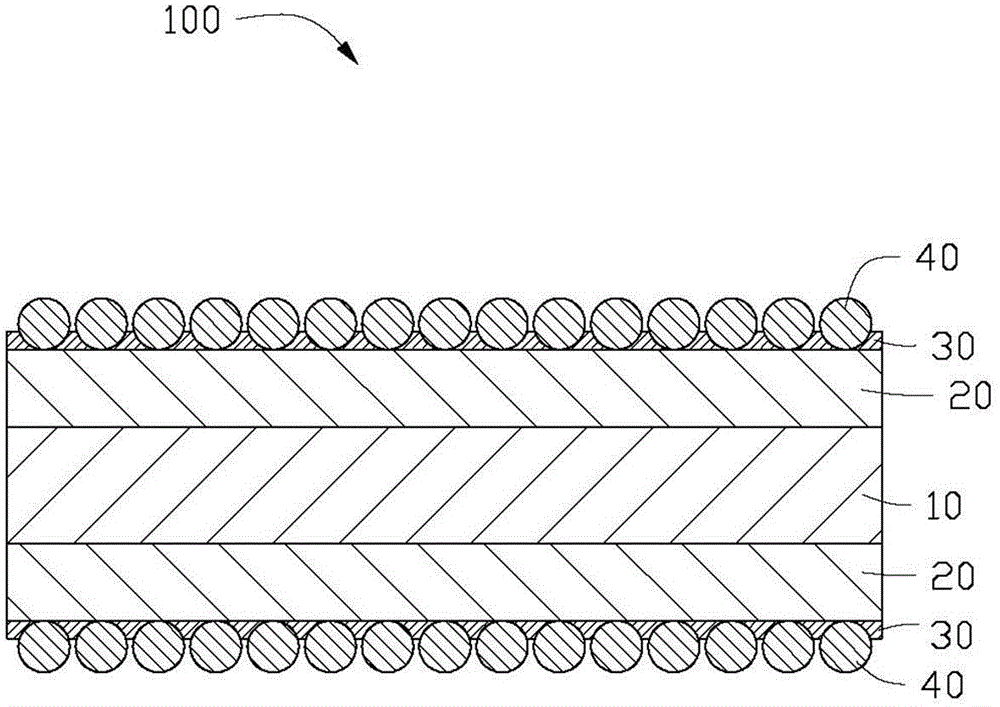

[0021] The preparation method of hydrophilic antibacterial ultrafiltration membrane provided by the invention comprises the following steps:

[0022] S10, providing a basic filter membrane;

[0023] S20, dissolving dopamine in tris (Tris) buffer solution to prepare a dopamine solution;

[0024] S30, coating the dopamine solution on the surface of the basic filter membrane to form a polydopamine coating layer on the surface of the basic filter membrane;

[0025] S40, coating the surface of the polydopamine coating layer with amino-decorated polyethylene glycol (Poly(ethylene glycol) methyl ether amine, mPEG-NH 2 ) solution to form a mPEG-NH on the surface of the polydopamine coating layer 2 Floor;

[0026] S50, in the mPEG-NH 2 Antibacterial nanoparticles are arranged on the surface of the layer to obtain the hydrophilic antibacterial ultrafiltration membrane.

[0027] In the step S10, the basic filter membrane is an ultrafiltration membrane, and the material of the ultraf...

Embodiment

[0045] In the specific embodiment of the present invention, the specific preparation process of the ultrafiltration membrane with hydrophilicity and antibacterial properties is as follows: a polysulfone ultrafiltration membrane is provided, and 2 g of dopamine is dissolved to a concentration of 0.01 mol L in 1 L -1 , pH = 8.5 Tris buffer solution, prepared to 2 g L -1 dopamine solution. Then the polysulfone ultrafiltration membrane was soaked in the dopamine solution for 3 hours, then taken out, and washed with ultrapure water to obtain the first filtration membrane. Soak the obtained first filter membrane in 1 g·L -1 mPEG-NH 2 solution, took it out after 1 hour, and washed it with ultrapure water to obtain the second filter membrane. Soak the second filter membrane in 500 mg·L -1 In the silver nitrate solution, take it out after 1 hour, and wash it with ultrapure water to obtain a hydrophilic antibacterial ultrafiltration membrane. Soak the hydrophilic antibacterial ultr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com