Alginate impression material

An impression material and alginate technology, which is applied in the direction of dental impression materials, stamping cups, medical science, etc., can solve problems such as the inability to meet the performance requirements of impression materials, and achieve enhanced toughness, good fluidity, and precision. high degree of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

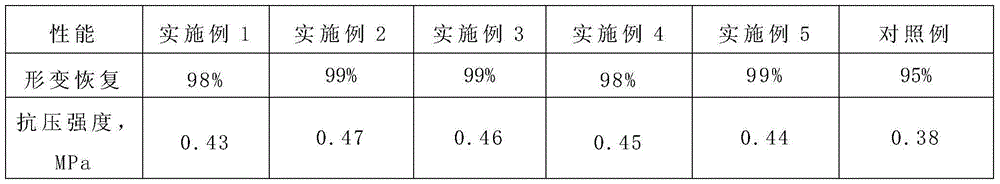

Examples

Embodiment 1

[0017] An alginate impression material, comprising the following raw materials in parts by mass: 10 parts of sodium alginate, 10 parts of calcium sulfate, 1 part of sodium phosphate, 60 parts of diatomaceous earth, 1 part of xanthan gum, and 1 part of nano silver 1 part, 1 part of potassium fluotitanate, 0.5 part of coloring agent, and 0.5 part of peppermint oil.

[0018] Add the above components into a high-speed mixer and mix for 20 minutes at a speed of 150 r / min to obtain the alginate impression material described in this example.

Embodiment 2

[0020] An alginate impression material, comprising the following raw materials in parts by mass: 12 parts of sodium alginate, 12 parts of calcium sulfate, 3 parts of sodium phosphate, 65 parts of diatomaceous earth, 2 parts of xanthan gum, and 1.6 parts of nano silver 1 part, 1.5 parts of potassium fluotitanate, 1 part of coloring agent, 1 part of peppermint oil.

[0021] Add the above components into a high-speed mixer and mix for 20 minutes at a speed of 150 r / min to obtain the alginate impression material described in this example.

Embodiment 3

[0023] An alginate impression material, comprising the following raw materials in parts by mass: 13 parts of potassium alginate, 13 parts of calcium sulfate, 3 parts of sodium pyrophosphate decahydrate, 66 parts of diatomaceous earth, 3 parts of xanthan gum, 1.8 parts of nano silver, 2 parts of potassium fluotitanate, 1.2 parts of colorant, 1.2 parts of peppermint oil.

[0024] Add the above components into a high-speed mixer and mix for 20 minutes at a speed of 150 r / min to obtain the alginate impression material described in this example.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com