High-temperature in situ tension-fatigue test system and test method thereof

A fatigue test and in-situ stretching technology, which is applied in the direction of applying stable tension/pressure to test the strength of materials, can solve the problems of inability to monitor microscopic deformation and damage, and achieve the effect of good scientific research application value, reliable principle and simple structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The detailed content of the present invention and its specific implementation will be further described below in conjunction with the accompanying drawings.

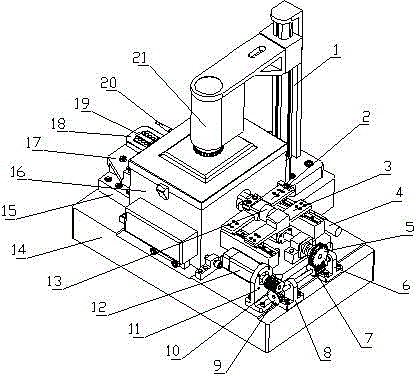

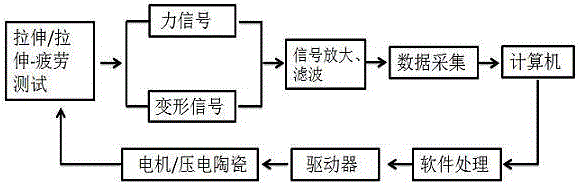

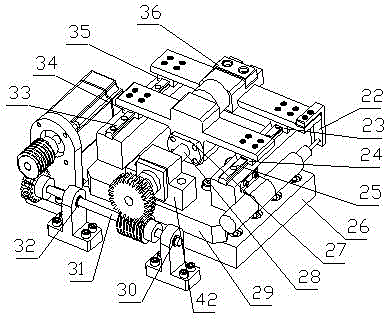

[0039] see Figure 1 to Figure 8 As shown, the high-temperature in-situ tensile-fatigue testing system of the present invention includes a tensile loading and detection unit, a fatigue loading and detection unit, an in-situ observation unit, a high-temperature loading and detection unit, etc., and the device is arranged horizontally, wherein the tensile loading The detection unit, fatigue loading and detection unit are respectively installed on both sides of the high temperature furnace, and the directions of tensile loading and fatigue loading are on the same axis. This test method realizes the uniaxial tensile-fatigue mechanical performance test of the material under the thermal field with adjustable temperature from 500°C to 1700°C, and realizes the whole process of microscopic deformation damage of the materia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com