Experimental test method of buried displacing oil storage quantity of mixed gas flooding under high temperature and high pressure

A high temperature and high pressure, mixed gas technology, applied in soil material testing, material inspection products and other directions, can solve the problems of accurate evaluation of insufficient gas storage volume, low experimental pressure, no experimental test method for oil displacement storage volume, etc., and achieves easy operation. , the principle is reliable, the effect of broad market prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] Further illustrate the present invention according to accompanying drawing and embodiment below.

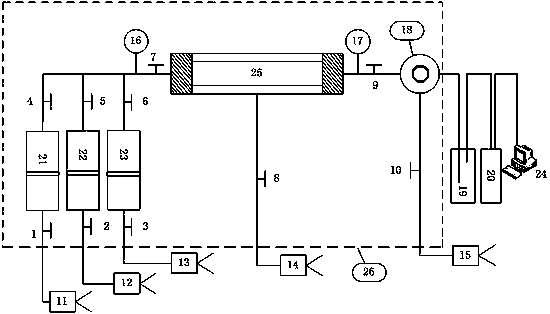

[0036] see figure 1 .

[0037] figure 1 It is a test device for long core gas flooding experiment, the device is mainly composed of formation water intermediate container 21, injected gas intermediate container 22, formation oil sample intermediate container 23, core holder 25, separator 19, gas meter 20, oven 26 composition, the left side of the core holder 25 is respectively connected to the formation water intermediate container 21 and the displacement pump A11, the injected gas intermediate container 22 and the displacement pump B12, the formation oil sample intermediate container 23 and the displacement pump C13, and the right side is respectively Connect the back pressure valve 18 and the back pressure pump 15, the separator 19 and the gas meter 20, the gas meter 20 is connected to the gas chromatograph 24; the rock core is housed in the core holder, and there are ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com