Fully automatic anchor rod drill carriage for coal mine

A bolt drilling rig, fully automatic technology, used in the installation of bolts, drill pipes, drill pipes, etc., can solve the problems of insufficient automation, long time and low efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

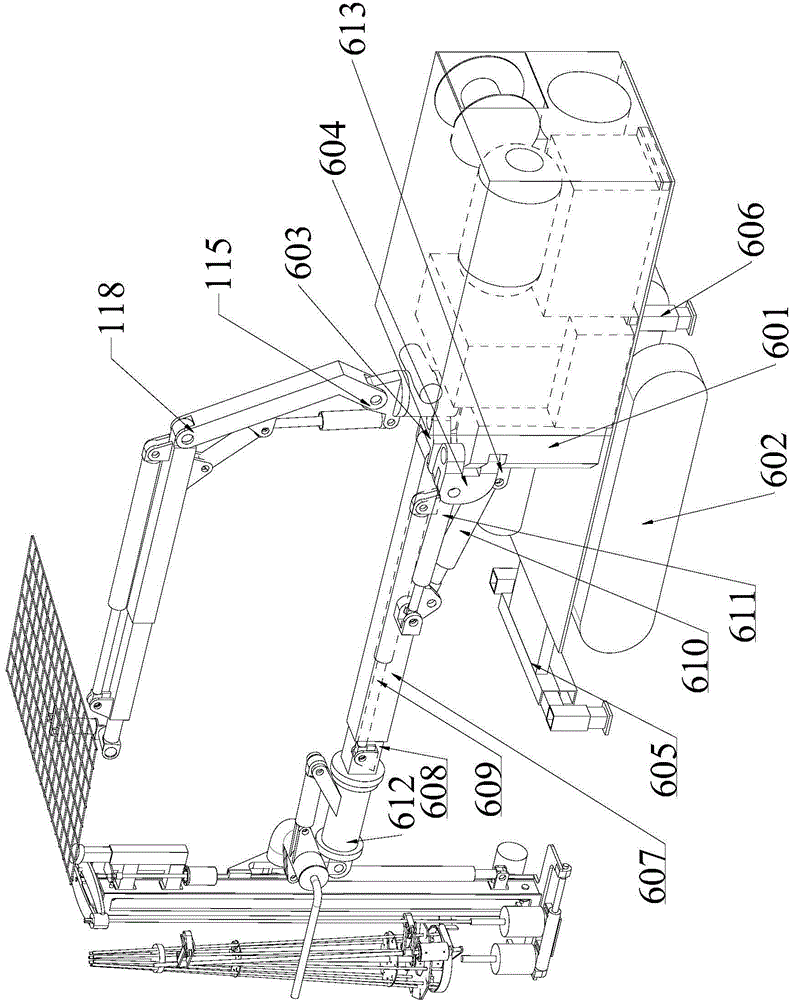

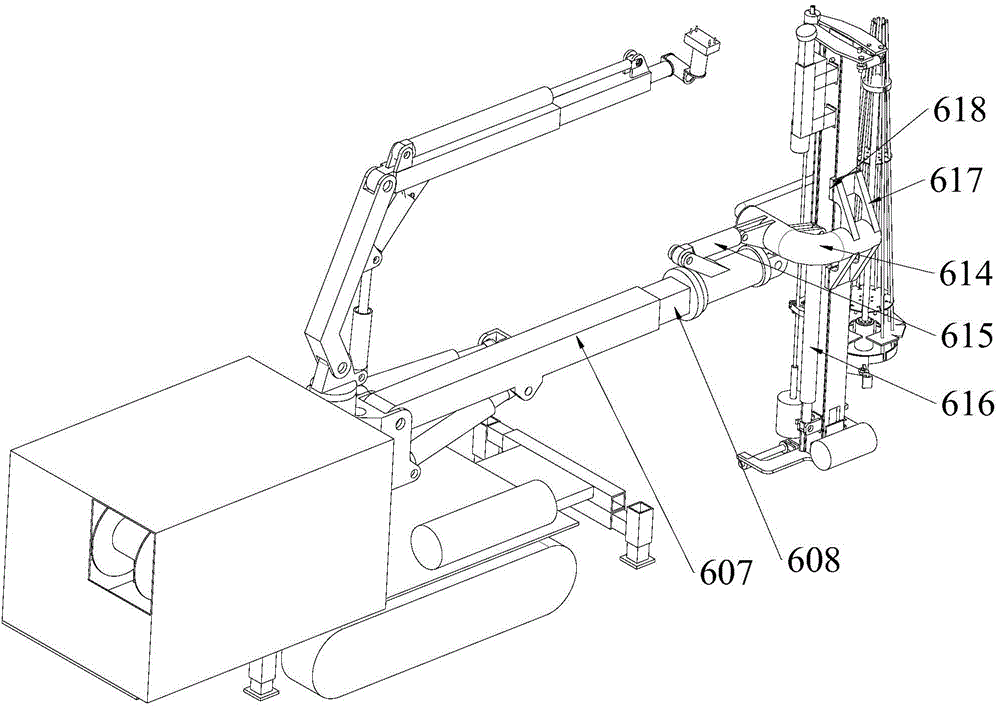

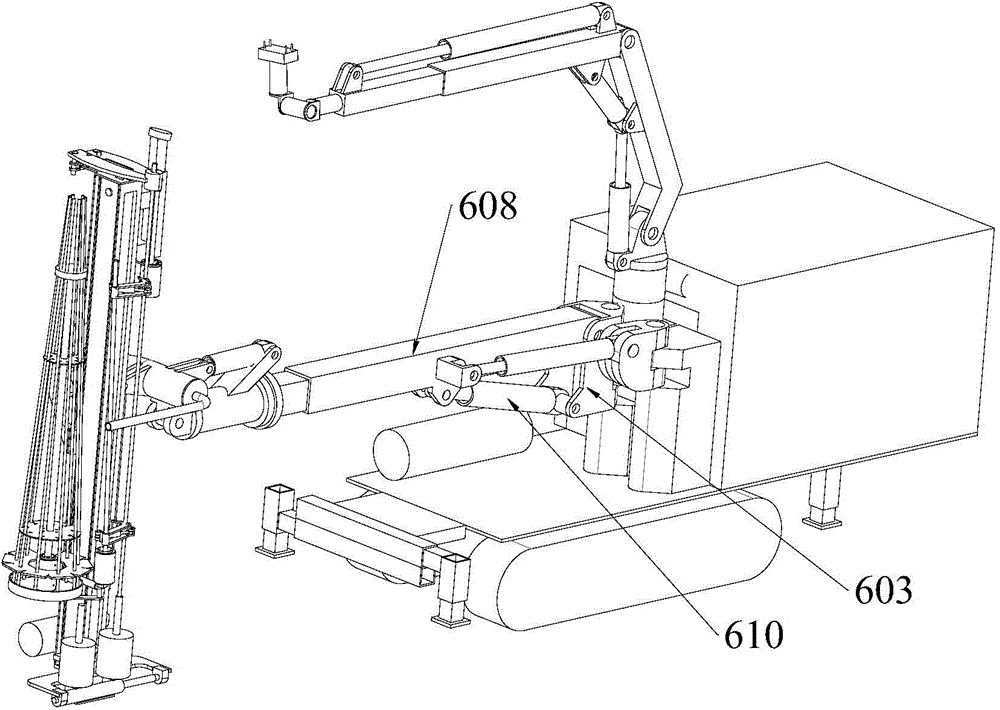

[0084] This embodiment provides a fully automatic rock bolter for coal mines, which includes a chassis 601, a crawler traction part 602, a boom swivel lug 603, a boom swivel oil cylinder lug 604, a front stabilizing mechanism 605, and a rear stabilizing mechanism 606 , boom telescopic cylinder 609, boom amplitude modulation cylinder 610, boom rotary cylinder 611, drill frame helical swing cylinder 612, guide rail sliding frame 614, drilling rig leveling cylinder 615, guide rail drive cylinder 616, automatic rock bolter for coal mine and Automatic laying device.

[0085] The chassis 601 is arranged horizontally; the crawler traction part 602 is fixed on the chassis 601 and is located at the lower part of the chassis 601, so as to realize the movement of the automatic rock bolter for coal mine through the crawler traction part 602 In this embodiment, the crawler traction unit 602 includes two crawlers, and the two crawlers are respectively located on the left and right sides of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com