a laying machine

A technology of a laying machine and a laying device, applied in the direction of construction and building structure, can solve the problems of long decoration period, fall of construction personnel, hidden safety hazards, etc., and achieve the effect of reasonable structural design, high degree of automation, and improved efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further elaborated below.

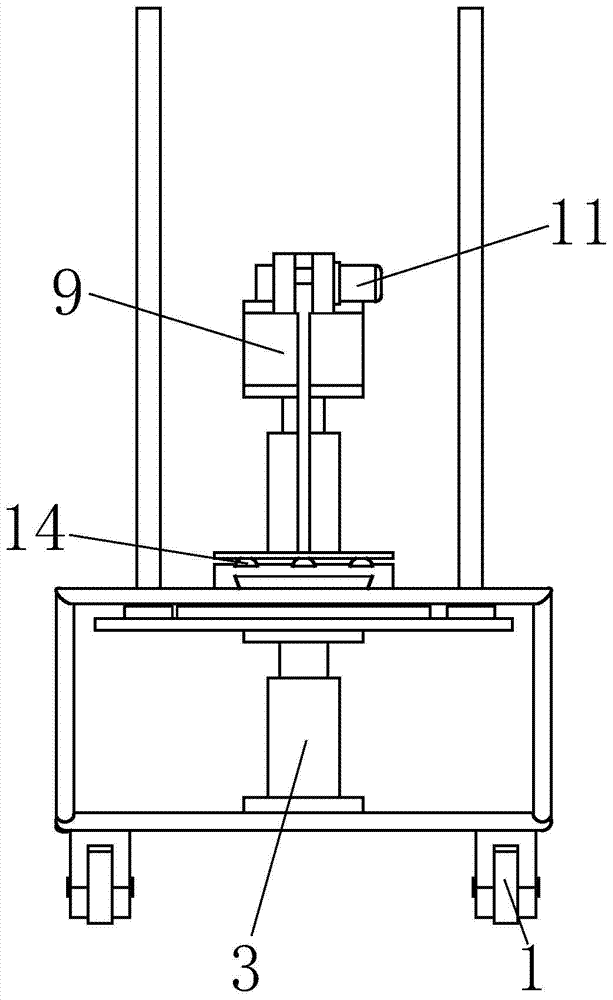

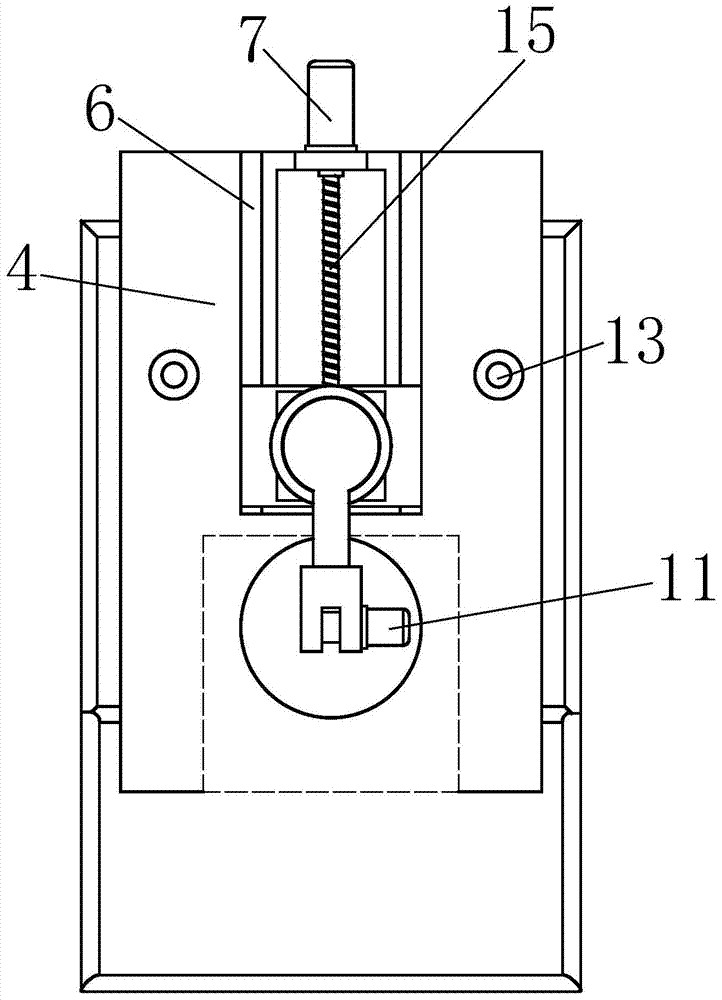

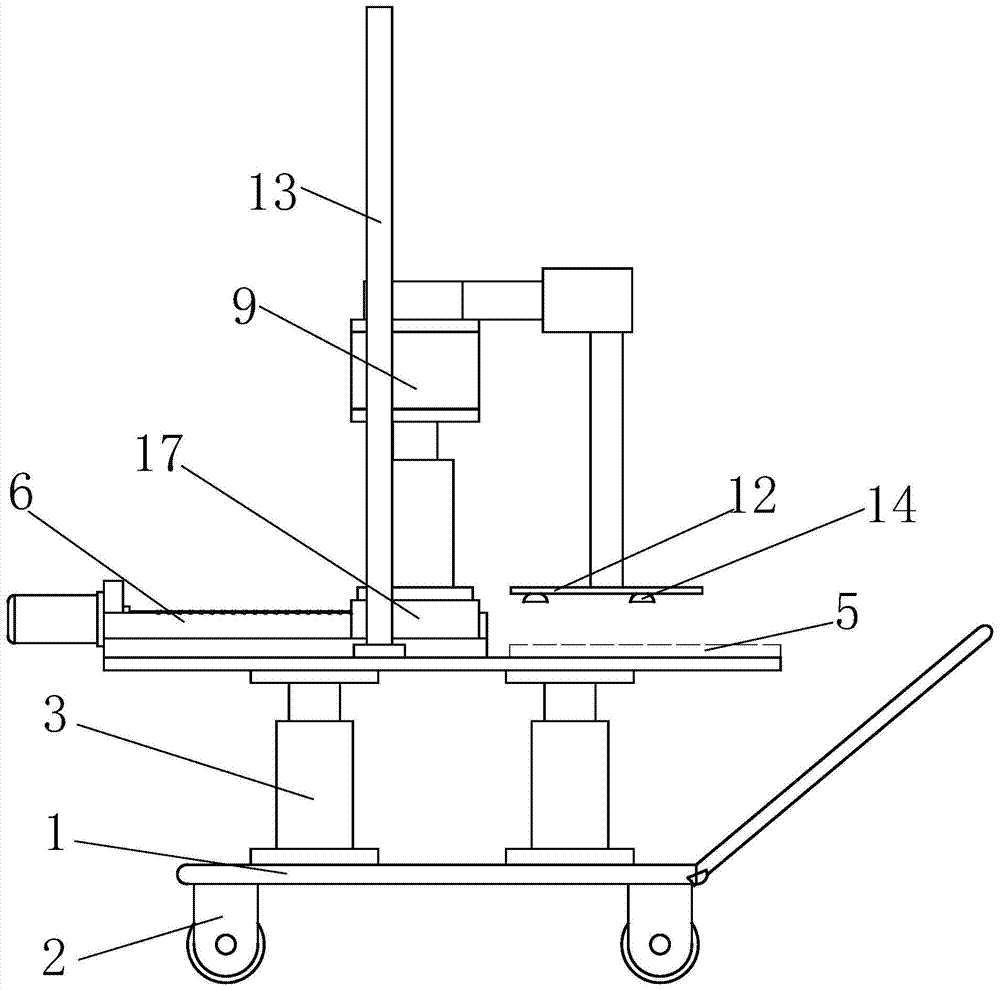

[0016] Such as Figure 1 to Figure 4 As shown, a laying machine includes a machine body 1, a walking wheel 2, a reference alignment device and a feeding and laying device, the walking wheel 2 is fixed on the bottom of the body 1, and the front part of the body 1 is provided with a handle 1a, The reference alignment device is installed on the upper end surface of the machine body 1, and the material feeding and laying device is installed in the middle of the upper end of the reference alignment device. When laying the ceiling 5, the operator first stacks the ceiling 5 on the datum alignment device, then pushes the handle 1a to move the body 1 to the right below the rectangular slot of the ceiling 5 fixing frame, and then starts the datum alignment device to perform datum Correction, aft...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com