Construction method of a carrier pile

A construction method and technology of carrier piles, applied in sheet pile walls, foundation structure engineering, construction, etc., can solve problems such as reduced work efficiency, large restrictions, pile length, etc., to improve construction work efficiency, expand application types, and increase construction speed Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

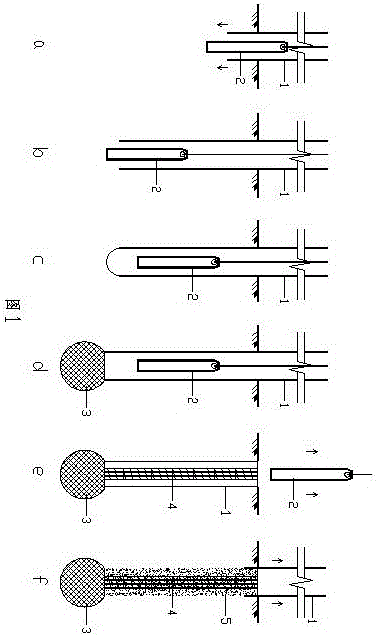

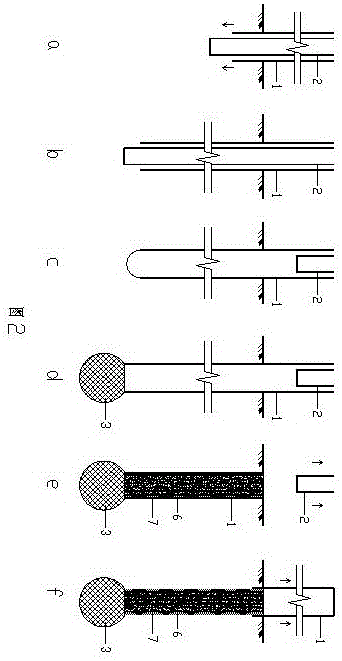

[0030] figure 1 It is a schematic diagram of an embodiment of the construction method of the carrier pile of the present invention, at first, as figure 1 As shown in a, at the pile position, through the free fall movement of the heavy hammer 2 in the casing 1, the foundation soil is punched to form pile holes and sink into the casing 1; then, as figure 1 As shown in middle b, sink the casing 1 and the weight 2 to the set depth, and drive the casing 1 out of the bottom of the weight 2 for a certain distance; then, as figure 1 As shown in middle c, in the casing 1, the soil mass at the bottom of the pile hole is tamped with the hammering kinetic energy of the weight 2, so that the soil mass at the pile tip is reinforced and compacted; then, as figure 1 As shown in d, repeat the above-mentioned tamping operation, and measure the penetration of the three-stroke penetration of the weight 1. When the measured value of the three-stroke penetration meets the design value, stop the ta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com