Carrier pile construction equipment and carrier pile construction method

A technology of construction equipment and construction method, applied in sheet pile wall, foundation structure engineering, construction and other directions, can solve the problems of reduced work efficiency, short pile body, inability to adjust, etc., to improve hole forming speed, expand application types, improve application range effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

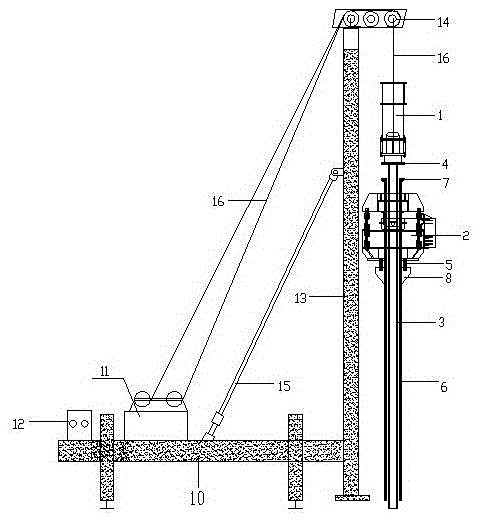

[0042] The present invention will be further described below in conjunction with the accompanying drawings.

[0043] figure 1 is a schematic diagram of an embodiment of the construction equipment of the carrier pile of the present invention, as figure 1 As shown, the equipment includes a chassis 10, a bracket 13, a support rod 15, an inner tube 3 and an outer tube 6. The chassis 10 can move back and forth, left and right, and a distribution box 12 and a hoist 11 are fixed on the chassis 10. The front end of the chassis 10 is provided with a vertical The bracket 13 on the chassis, the bracket 13 is a single rod type or a door frame type, the top of the bracket 13 is provided with a pulley block 14, the bracket 13 is supported on the chassis 10 through the support rod 15, and the inner tube 3 can be inserted or raised in the outer tube 6, specifically The feature is: a hammering device, a vibrating device and a suspension device are installed on the bracket 13, the hammering de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com