Construction method for carrier pile of major diameter long pile

A construction method and carrier pile technology, applied in sheet pile wall, foundation structure engineering, foundation structure test and other directions, can solve the problems of difficulty in completing larger and longer diameter piles, difficult application, etc., to expand application types and Scope of application, low equipment cost and construction cost, and the effect of improving hole forming speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described below in conjunction with the accompanying drawings.

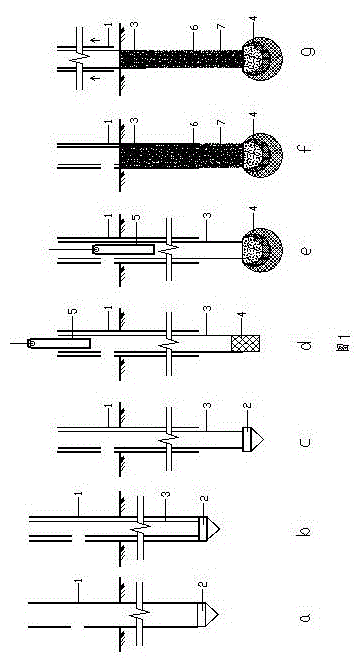

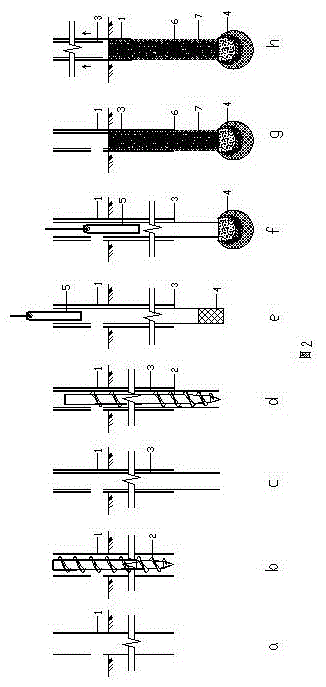

[0035] figure 1 It is the process drawing of an embodiment of the construction method of the concrete pile of the large-diameter long pile of the present invention, and the hole forming of the pile body of this embodiment adopts the method of squeezing the soil to form the hole. At first, as figure 1 As shown in a, at the pile position in the foundation, by applying vibration force to the A casing 1, the A casing 1 with the prefabricated pile tip 2 is sunk to the set depth; then, as figure 1 As shown in middle b, in the inner cavity of A casing 1, the B casing 3 whose length is greater than A casing 1 is sunk; then, as figure 1 As shown in c, the vibration force is applied to the B casing 3, and the B casing 3 drives the prefabricated pile tip 2 to sink down to the set depth; then, as figure 1 As shown in middle d, a certain amount of filling material 4 is filled in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com