Conveniently-operated ball surface spray welding device for ball valve

一种操作方便、球体的技术,应用在熔融喷镀、金属材料涂层工艺、涂层等方向,能够解决加工工艺效率低、操作环境差、工作强度大等问题,达到结合面应力小、结构合理、加工效率高的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

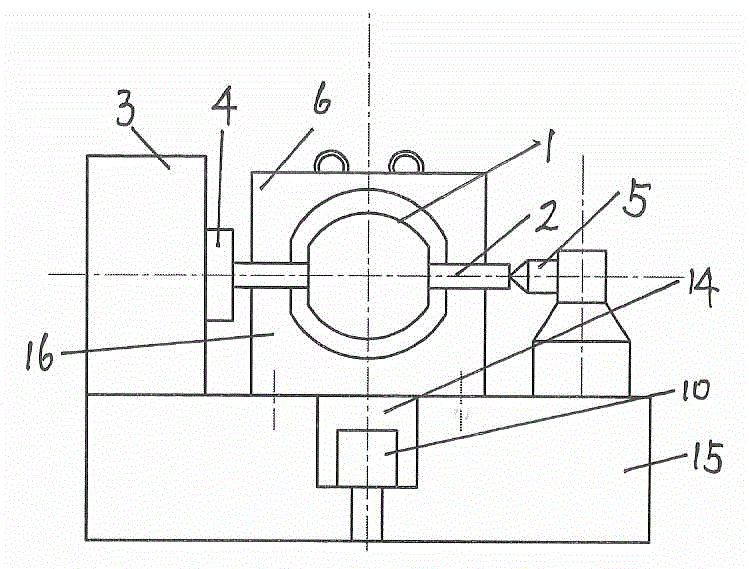

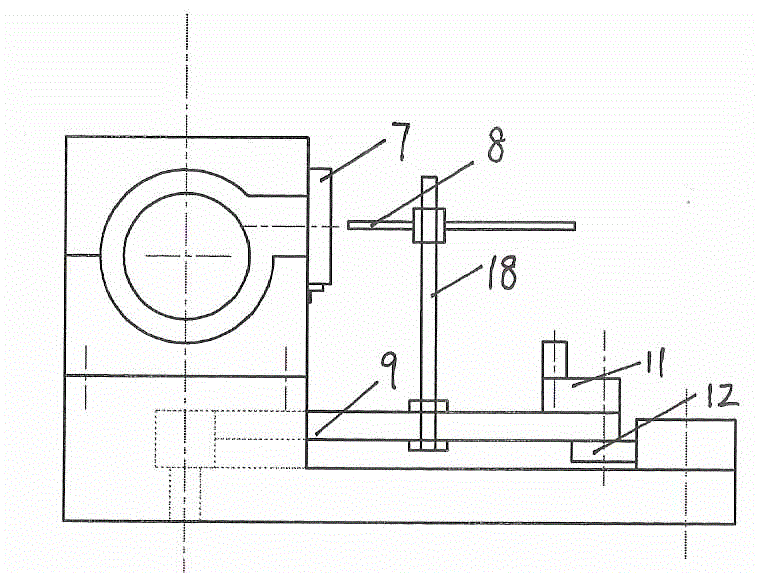

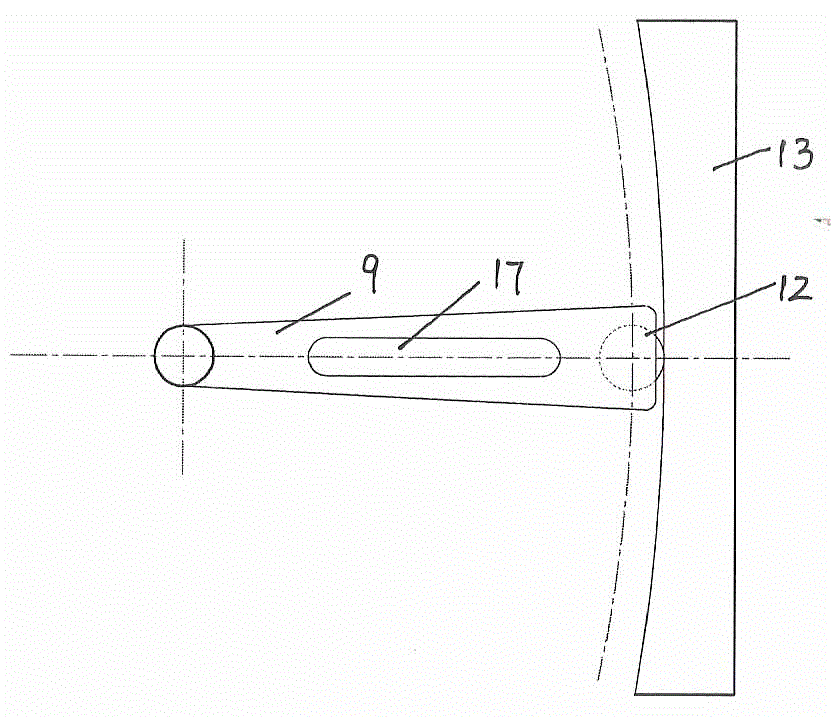

[0017] A ball surface spray welding device for a ball valve, comprising a temperature control box, a reduction box, a tailstock, a spray gun, and a spray gun swing mechanism. The temperature control box includes an upper box body 6 and a lower box body 16. There is a spray gun door, and the upper box is covered on the lower box. There is a cavity for placing the sphere in the temperature control box. The elastic mandrel passes through the hole of the sphere and fits tightly with the sphere; the two ends of the mandrel pass through the reduction box respectively. The front end chuck and the tailstock are tightened; the spray gun is arranged outside the spray gun door 7, and the spray gun is connected with the spray gun swing mechanism; the swing mechanism includes a support plate 9 fixedly connected with the spray gun seat 18 of the spray gun 8, and one end of the support plate is sleeved on the support shaft 10, the other end of the support plate is fixedly connected with the g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com