Method for classifying and recycling multiple resins in mixed waste paint

A recycling method and resin technology, applied in the direction of plastic recycling, recycling technology, coating, etc., to achieve high economic benefits, high resin recovery rate, and high economic efficiency of waste recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] (1) The No. 1 sample of dark mixed paint residue obtained from a certain company, foreign matter and mechanical impurities were manually removed, and dehydrated by simple mechanical extrusion, and then put into a vacuum drying oven at 25°C for 6 hours at room temperature.

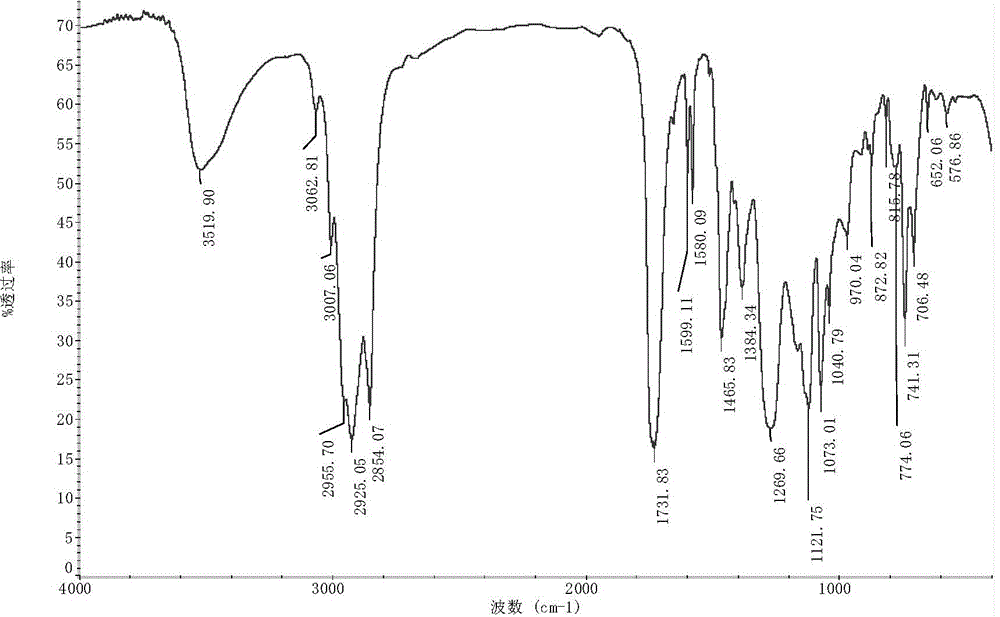

[0043] (2) Cut 100g sample from the dried paint slag, place it in a reaction kettle with agitator, add 150mL of a mixed solvent of No. 200 solvent gasoline and xylene (solvent 1) (volume ratio 60:40), and keep the temperature at 25 Stir at ℃ for 12 hours, after standing still, filter and separate the insoluble paint slag and mixed solvent, the obtained filtrate 1 is adsorbed with activated carbon, and after vacuum distillation, 61g of recovered resin product mainly based on alkyd resin is obtained, and its infrared spectrum Figure such as figure 1 shown. The saturated V of strong medium- and long-chain fatty acids can be seen in the figure. C-H (2955-2850cm -1 ),δ C-H (700-740cm -1 ), unsaturate...

Embodiment 2

[0052] (1) The No. 2 sample of colorless mixed paint waste obtained from a certain enterprise, foreign matter and mechanical impurities were manually removed, and subjected to simple extrusion dehydration, and then dried in a vacuum drying oven at room temperature of 50°C for 0.5 hours.

[0053] (2) Cut 100g sample from the dried paint slag, place it in a reaction kettle with agitator, add 400mL of a mixed solvent of No. 200 solvent gasoline and xylene (solvent 1) (volume ratio 100:0), and keep the temperature at 50 Stir at ℃ for 5 hours, and after standing still, filter and separate the insoluble paint residue from the mixed solvent. The obtained filtrate 1 is colorless and transparent, so it does not need to be adsorbed by activated carbon. After vacuum distillation, the recovered resin product mainly composed of alkyd resin is obtained. 38g.

[0054] (3) Add 400mL xylene (solvent 2) to the filter residue, stir at a constant temperature of 50°C for 5 hours, and after standin...

Embodiment 3

[0058] (1) The No. 1 sample of dark mixed paint waste obtained from a certain enterprise, foreign matter and mechanical impurities were manually removed, and simple extrusion dehydration was carried out, and then dried in a vacuum drying oven at room temperature of 37°C for 3 hours.

[0059] (2) Cut 100g sample from the dried paint slag, put it in a reaction kettle with agitator, add 250mL solvent gasoline and xylene mixed solvent (solvent 1) (volume ratio 70:30), keep the temperature at 37°C Stir down for 8 hours, after standing, the insoluble paint slag and the mixed solvent are filtered and separated, and the obtained filtrate 1 is adsorbed with activated carbon, and after vacuum distillation, 52g of the recovered resin product based on alkyd resin is obtained.

[0060] (3) Add 250mL xylene (solvent 2) to the filter residue, stir at a constant temperature of 37°C for 8 hours, and after standing, filter and separate the insoluble paint residue from the solvent. The obtained f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com