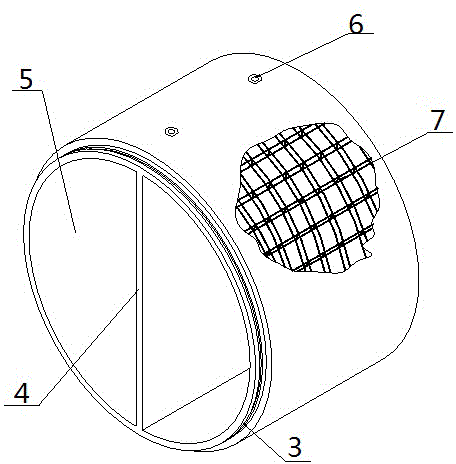

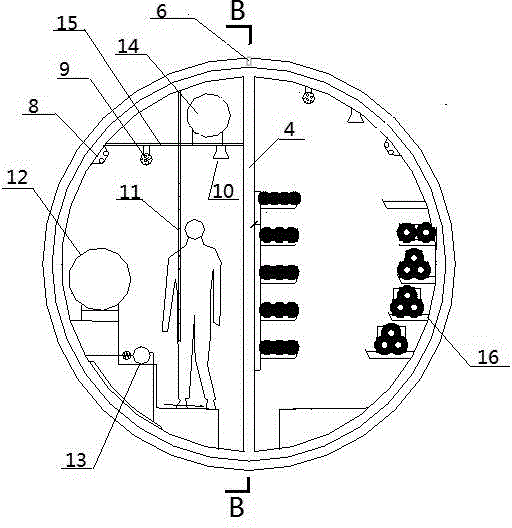

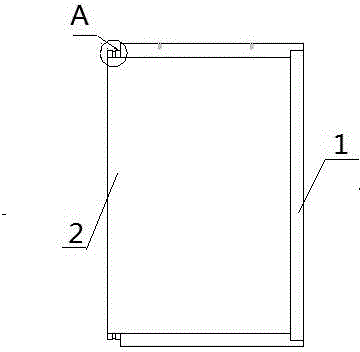

Assembly type lightweight thin wall integrated pipe gallery and production method thereof

A comprehensive pipe gallery and prefabricated technology, applied in the field of municipal comprehensive pipelines, can solve the problems of small self-weight, achieve low cost, reduce the amount of foundation excavation and backfill, and reduce the thickness of the structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0063] A prefabricated light-weight and thin-walled comprehensive pipe gallery is cast with ultra-high-performance powder concrete, and the ultra-high-performance powder concrete includes the following components by weight:

[0064] 900 parts of 42.5 grade ordinary Portland cement with an average particle size of 30-60 μm;

[0065] 100 parts of micro-silicon powder with an average particle size of 5-20 μm and a SiO2 content of ≥85%;

[0066] 45 parts of limestone powder with an average particle size of 10-30 μm;

[0067] 30 parts of nanometer calcium carbonate powder;

[0068] 550 parts of continuously graded pottery sand with particle size below 2.5;

[0069] 16 parts of high-efficiency water reducing agent with water reducing rate greater than 30%;

[0070] 220 parts of water;

[0071] 130 copper-plated fibers with an average diameter of 0.20 mm and a length of 12 to 15 mm;

[0072] 80 copper-plated fibers with an average diameter of 0.12mm and a length of 6-10mm;

[0...

Embodiment 2

[0084] A prefabricated light-weight and thin-walled comprehensive pipe gallery is cast with ultra-high-performance powder concrete, and the ultra-high-performance powder concrete includes the following components by weight:

[0085] 950 parts of 42.5 grade ordinary Portland cement with an average particle size of 30-60 μm;

[0086] 120 parts of micro-silicon powder with an average particle size of 5-20 μm and a SiO2 content of ≥85%;

[0087] 50 parts of limestone powder with an average particle size of 10-30 μm;

[0088] 35 parts of nanoscale calcium carbonate powder;

[0089] 600 parts of continuously graded pottery sand with particle size below 2.5;

[0090] 18 parts of high-efficiency water reducing agent with water reducing rate greater than 30%;

[0091] 230 parts of water;

[0092] 130 copper-plated fibers with an average diameter of 0.20 mm and a length of 12 to 15 mm;

[0093] 80 copper-plated fibers with an average diameter of 0.12mm and a length of 6-10mm;

[0...

Embodiment 3

[0101] Except that the formula ratio of ultra-high performance powder concrete is different, other is the same as embodiment 1;

[0102] The ultra-high performance powder concrete includes the following components in parts by weight:

[0103] 1,000 parts of 42.5 grade ordinary Portland cement with an average particle size of 30-60 μm;

[0104] 130 parts of micro-silicon powder with an average particle size of 5-20 μm and a SiO2 content of ≥85%;

[0105] 53 parts of limestone powder with an average particle size of 10-30 μm;

[0106] 40 parts of nanoscale calcium carbonate powder;

[0107] 630 parts of continuously graded pottery sand with particle size below 2.5mm;

[0108] 19 parts of high-efficiency water reducing agent with water reducing rate greater than 30%;

[0109] 240 parts of water;

[0110] 130 copper-plated fibers with an average diameter of 0.20 mm and a length of 12 to 15 mm;

[0111] 80 copper-plated fibers with an average diameter of 0.12mm and a length o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com