High-magnesium waste rock powder-based composite mineral admixture and its application in high-strength concrete

A technology of composite minerals and admixtures, which is applied in high-magnesium waste rock powder-based composite mineral admixtures and high-strength concrete applications, and can solve the problems of restricting the promotion and application of wet fly ash, surrounding environmental pollution, and high impurity content. Problems, to achieve obvious economic and social benefits, reduce pollution, reduce the effect of cement consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~6

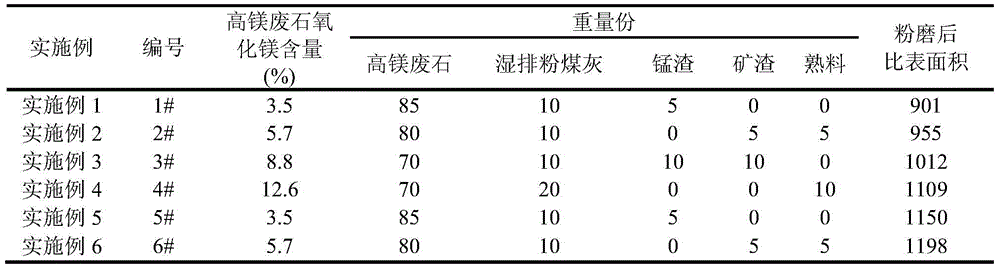

[0042] Dry the high-magnesium waste rock, wet-discharged fly ash, manganese slag, and slag until the moisture content is below 1.0%, and put them into a ball mill to grind the clinker according to the ratio in Table 1 to the corresponding specific surface area, and obtain 6 composite blends The materials are numbered 1#~6# respectively.

[0043] Table 1. Mixing ratio and fineness of high-magnesium waste rock powder-based composite mineral admixture

[0044]

[0045]The clinker used is ordinary Portland cement clinker produced by Guangxi China Resources Hongshuihe Cement.

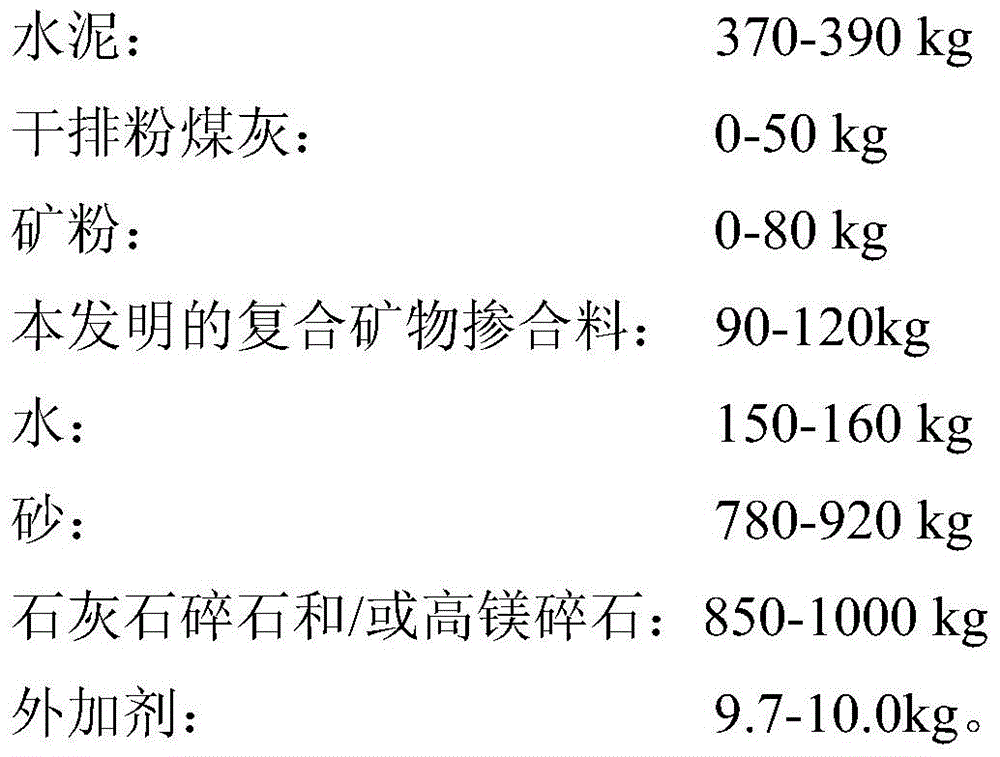

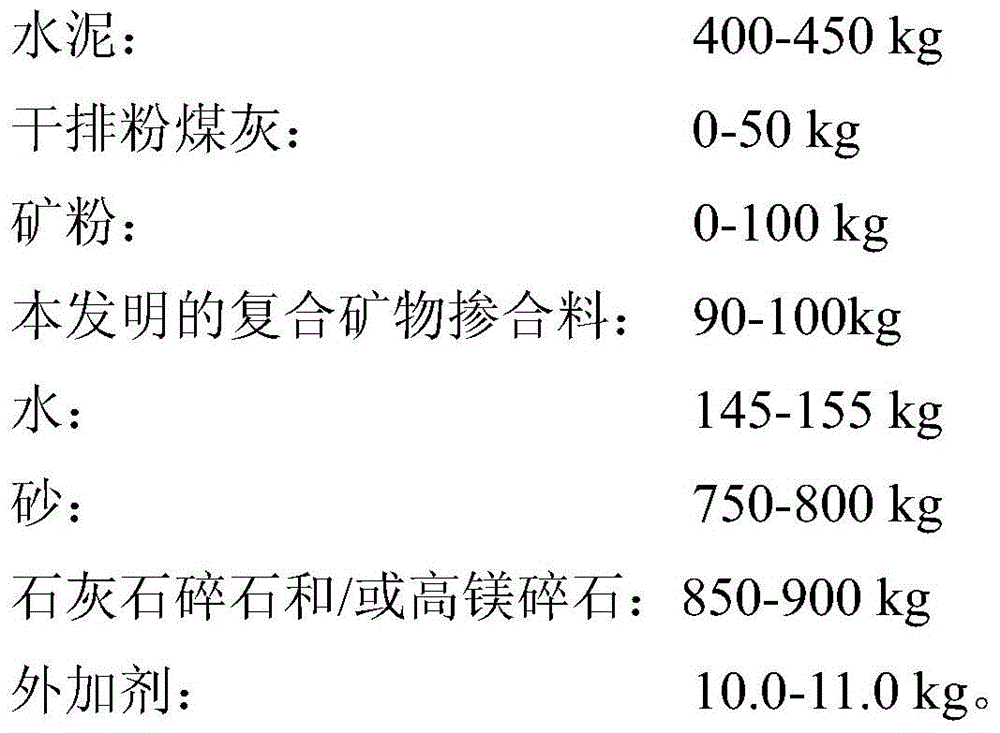

[0046] In order to better reflect the effect of the composite admixture of the present invention, the admixtures of the above six embodiments are used in high-strength concrete, and the corresponding C65 and C70 examples are selected for comparison. The test was carried out in accordance with the test method for mechanical properties of ordinary concrete (GB / T50081-2002) and the test method for performan...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com