Spiral jet aerator

A jet aeration and spiral technology, which is applied in water aeration, sustainable biological treatment, water/sludge/sewage treatment, etc., can solve the problems of low dissolved air efficiency, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

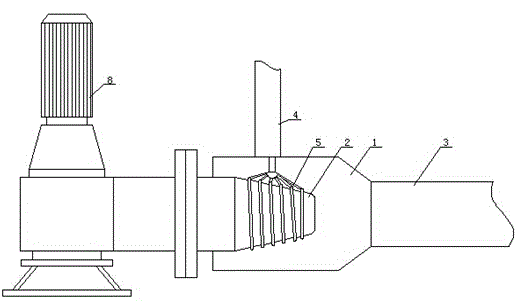

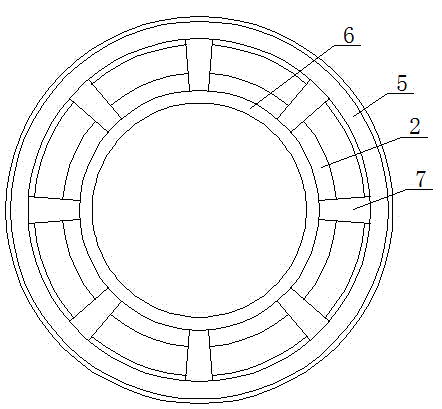

[0027] The spiral jet aerator of this embodiment includes a water pump, the water pump is connected with an aerator, the aerator includes a suction chamber and a nozzle, the nozzle is inserted from one end of the suction chamber, and the suction The other end of the air chamber is connected with a throat, and the suction chamber is also connected with a suction pipe. The inside of the nozzle is provided with a spiral deflector, and a number of through holes are opened on the nozzle between adjacent spiral deflectors. , the suction pipe is connected with at least two air intake branch pipes, the air intake branch pipes are sleeved on the periphery of the nozzle, the air intake branch pipes are evenly provided with air inlets with the same number of through holes, and the air inlets It communicates with the through hole through the pipeline.

Embodiment 2

[0029] The spiral jet aerator of this embodiment includes a water pump, the water pump is connected with an aerator, the aerator includes a suction chamber and a nozzle, the nozzle is inserted from one end of the suction chamber, and the suction The other end of the air chamber is connected with a throat, and the suction chamber is also connected with a suction pipe. The inside of the nozzle is provided with a spiral deflector, and a number of through holes are opened on the nozzle between adjacent spiral deflectors. , the suction pipe is connected with at least two air intake branch pipes, the air intake branch pipes are sleeved on the periphery of the nozzle, the air intake branch pipes are evenly provided with air inlets with the same number of through holes, and the air inlets It communicates with the through hole through the pipeline; the through hole is obliquely set on the nozzle.

Embodiment 3

[0031]The spiral jet aerator of this embodiment includes a water pump, the water pump is connected with an aerator, and the aerator includes a suction chamber and a nozzle, the nozzle is inserted from one end of the suction chamber, and the suction The other end of the air chamber is connected with a throat, and the suction chamber is also connected with a suction pipe. The inside of the nozzle is provided with a spiral deflector, and a number of through holes are opened on the nozzle between adjacent spiral deflectors. , the suction pipe is connected with at least two air intake branch pipes, the air intake branch pipes are sleeved on the periphery of the nozzle, and the air intake branch pipes are evenly provided with air inlets with the same number of through holes, and the air inlets The through hole communicates with each other through a pipeline; the through hole is obliquely opened on the nozzle; the through hole is inclined along the spraying direction of the nozzle.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com