Semi-automatic inching system of hydraulic variable-torque forklift

A hydraulic torque conversion, semi-automatic technology, applied in the field of semi-automatic inching system of hydraulic torque conversion forklift, can solve the problems of easy driver fatigue, affect labor efficiency, low forklift operation efficiency, etc., and achieve comfortable operation experience and portability. The effect of strengthening and improving labor efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

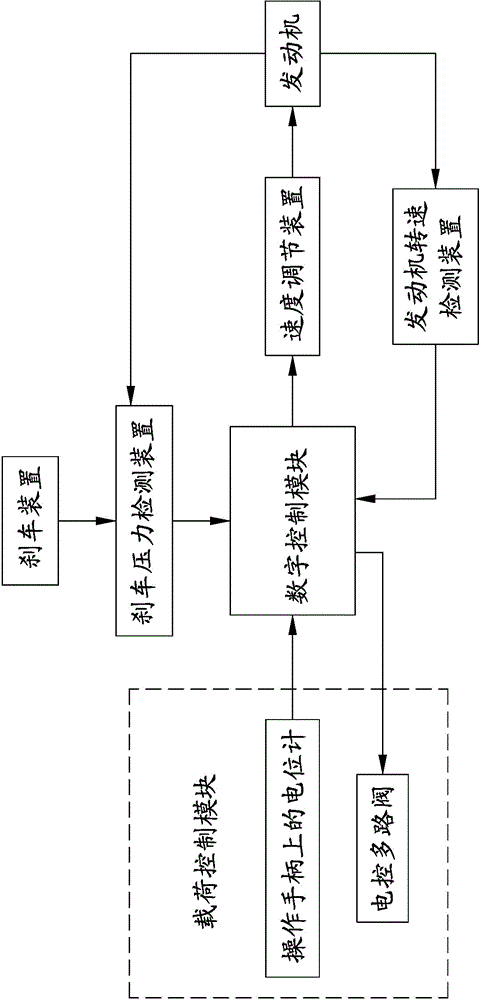

[0018] like figure 1 As shown, the hydraulic torque converter forklift semi-automatic inching system disclosed by the present invention includes a digital control module, a load control module, an engine speed adjustment device and a brake pressure detection device. The load control module is composed of an operating handle and an electronically controlled multi-way valve. The operating handle is provided with a potentiometer that converts the mechanical stroke into a voltage change, and the electronically controlled multi-way valve in this embodiment is a hydraulic control valve. The input terminal of the digital control module is connected with a potentiometer on the operating handle, a brake pressure detection device and an engine speed detection device. The brake pressure detection device in this embodiment is a brake pressure sensor, and the engine speed detection device is an engine speed sensor. The output end of the digital control module is connected with an electron...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com