Grab ship unloader and its driving method and device

A driving method and a grabbing bucket technology, which are applied in the direction of transportation and packaging, load hanging components, etc., can solve problems such as collisions with people on cargo ships or docks, high labor intensity, and damage to the power source of the opening and closing drums, so as to reduce collisions probability, reduce labor intensity, and improve safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described in detail below through specific embodiments in conjunction with the accompanying drawings.

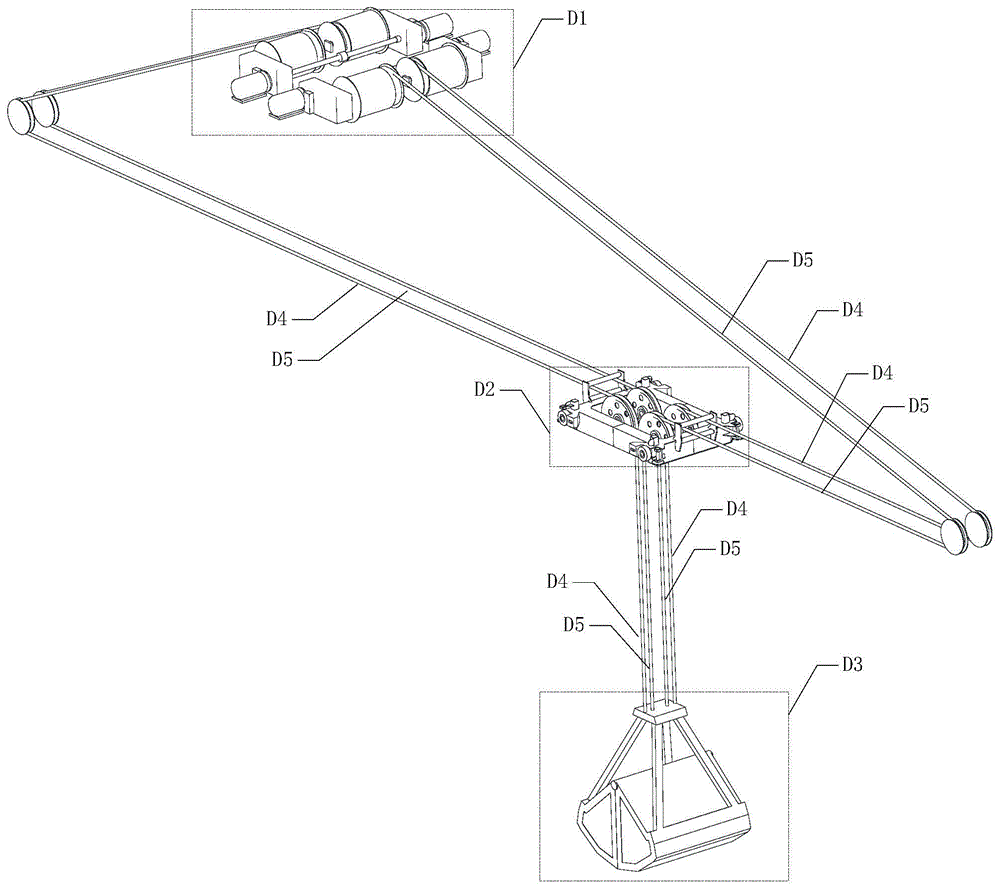

[0021] Please refer to figure 1 , is a structural schematic diagram of a grab ship unloader disclosed in this embodiment, including: a grab driving mechanism D1, a grab D3 and a trolley D2 carrying the grab D3, and the trolley D2 is used to drive the grab D3 to move, wherein , the grab D3 is sequentially connected to the trolley D2 and the lifting reel in the grab drive mechanism D1 through the lifting rope D4; Close the reel. In a specific embodiment, the lifting drum in the grab drive mechanism D1 realizes the movement of the trolley by winding / releasing the lifting rope D4, thereby driving the grab bucket D3 to move; the opening and closing drum in the grab bucket drive mechanism D1 passes Coil / release the opening and closing rope D5 to realize the opening and closing of the grab bucket D3.

[0022] Please refer to figure ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com