A laser scribing device for coating material and adjustable scribing distance

An adjustable, membrane material technology, applied in metal processing and other directions, can solve problems such as excessive force, scratches on the product surface, and poor force exertion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

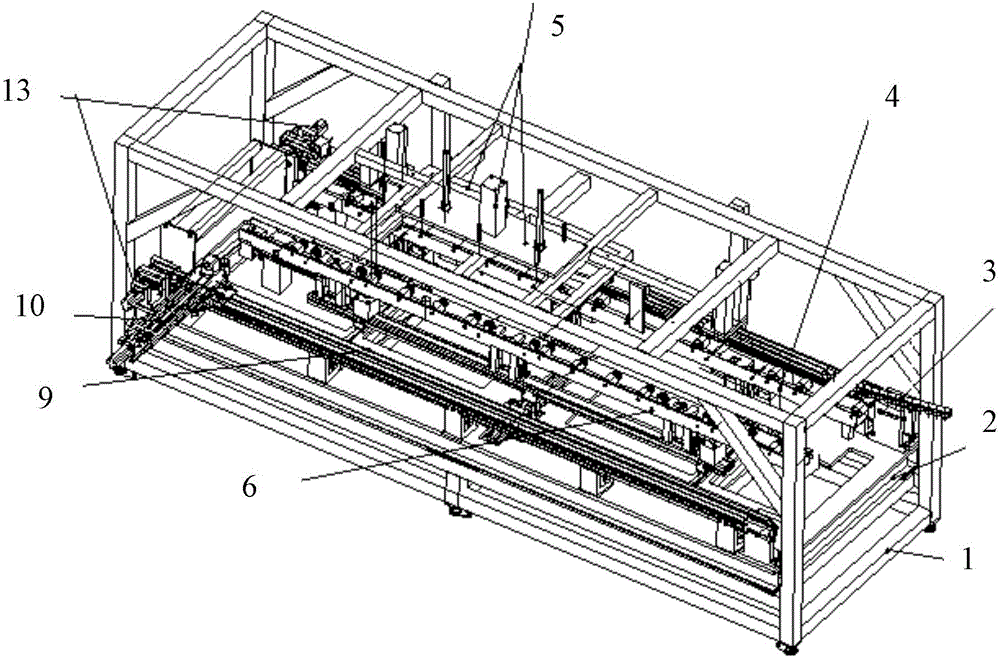

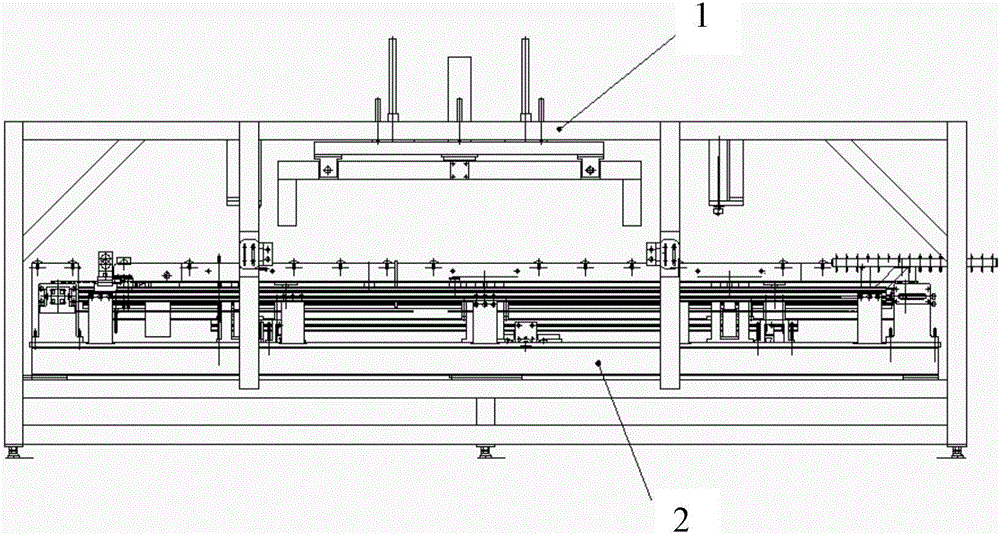

[0032] The laser scribing device for film coating material and adjustable scribing pitch provided by the present invention will be described in detail below with reference to the drawings and specific embodiments.

[0033] Such as figure 1 — Picture 12 As shown, the laser scribing device for film coating materials and adjustable scribing distance provided by the present invention includes a frame body 1, a carrier body 2, a guide rail 3, a fixed end assembly of a roller table 4, an upper centering-down pressing mechanism 5. The movable end assembly of the roller table 6, the two side wall lower pressing parts 7, the lower centering mechanism 8, the two slide rail tables 9, the movable laser fixing seat 10, the laser fixing seat 11 and the controller;

[0034] The frame 1 is a rectangular parallelepiped frame structure;

[0035] The supporting body 2 is a plate-shaped structure, which is horizontally arranged on the inner bottom surface of the frame body 1, and a long groove is form...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com