Powder material feeding system

A powder and powder bag technology, applied in the field of liquid and powder mixing process equipment, can solve problems such as increased operating costs, physical hazards to operators, uneven mixing, etc., to improve production and processing capabilities, reduce labor intensity, reduce The effect of equipment investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

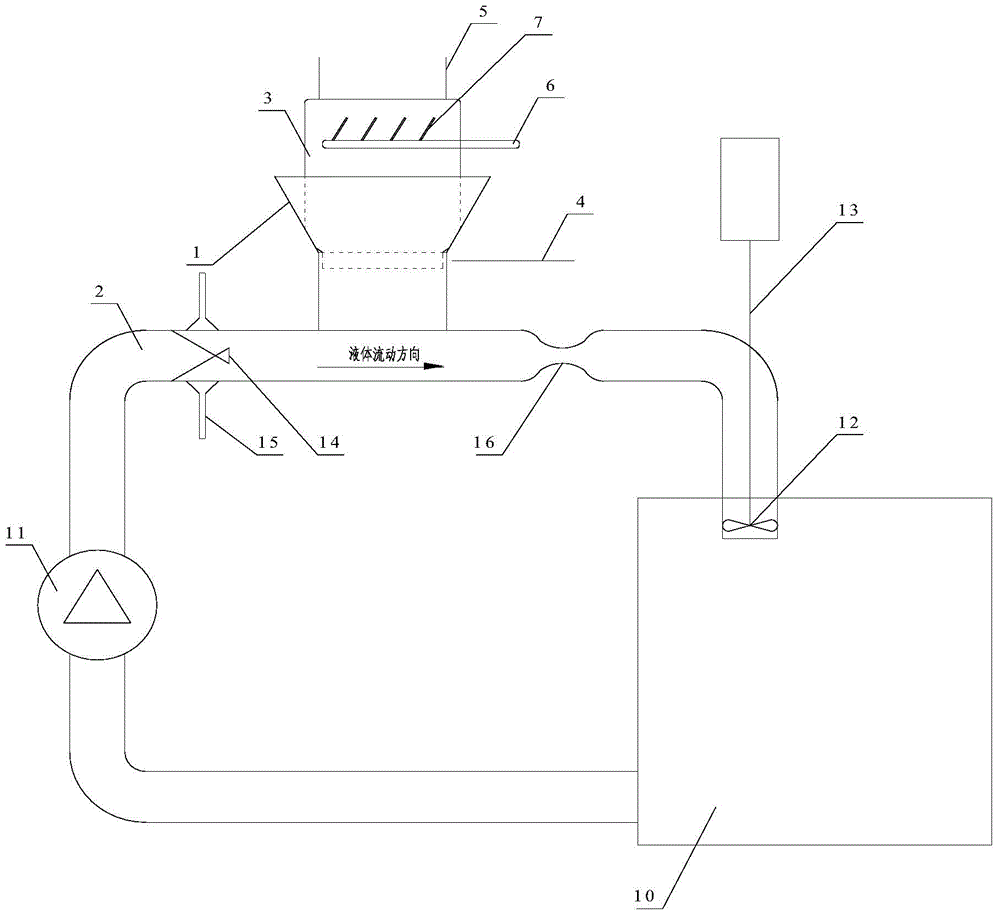

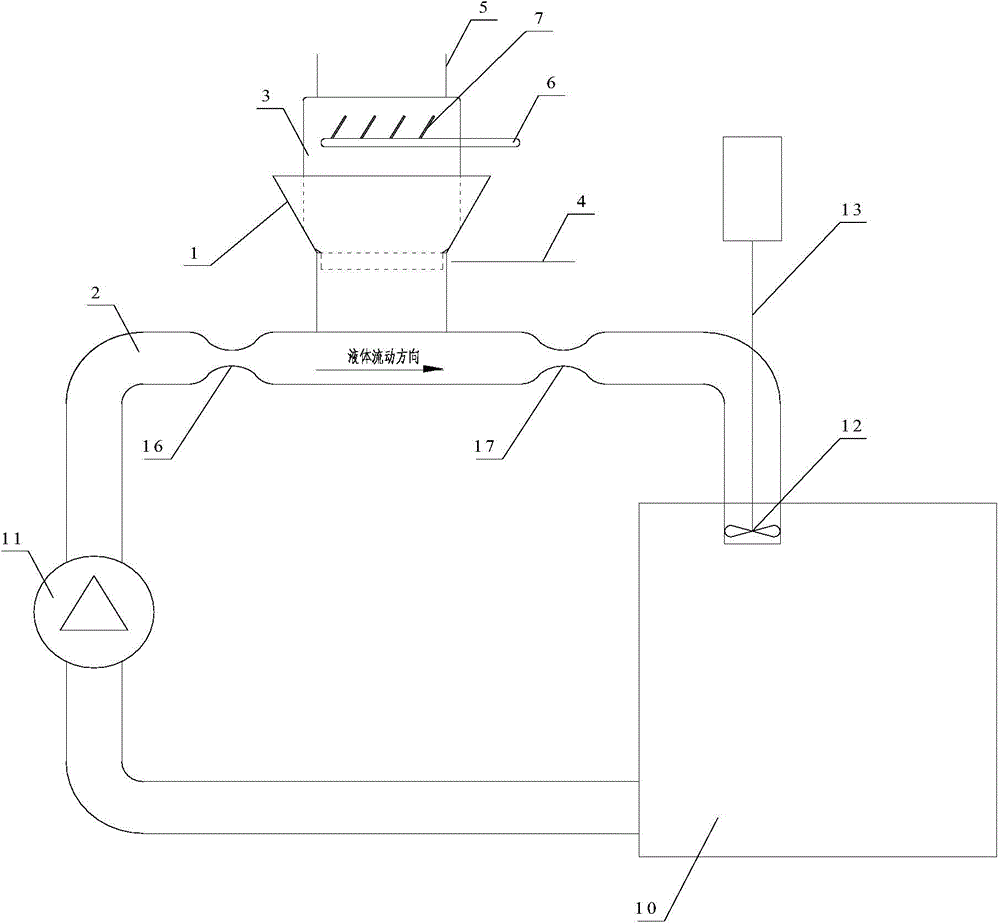

[0028] Such as figure 1 As shown, a powder feeding system includes a feeding device 1, a circulation pipeline 2 sealed with the discharge end of the feeding device 1,

[0029] The inner diameter of the upper part of the feeding device 1 gradually decreases, and when one end of the powder bag 3 is placed on the feeding device 1, the powder bag 3 is in close contact with the inner wall of the feeding device 1,

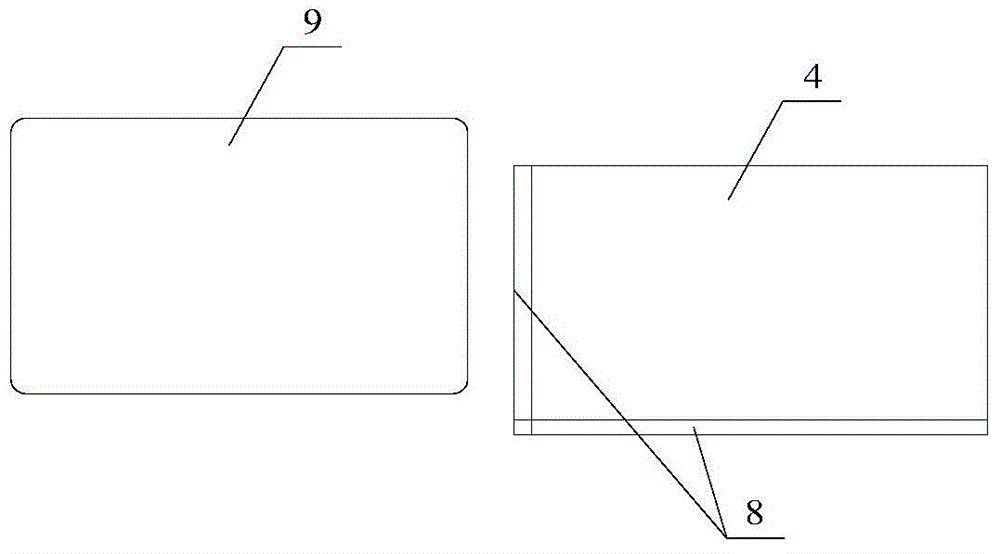

[0030] The lower part of the feeding device 1 is provided with a cutting knife 4, which is used to cut the end of the powder bag 3 into the feeding device.

[0031] When the cutting knife 4 cuts the powder bag 3, the powder falls into the circulation pipeline 2, and at the same time, the liquid in the circulation pipeline 2 flows, forming a negative pressure at the outlet of the feeding device 1, and further sucking the powder In the circulation pipeline, it can also effectively prevent the powder from flying.

[0032] The feeding device 1 can be divided into upper and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com