Phase-change temperature control mobile phone shell

A phase-change temperature control and mobile phone case technology, applied in the direction of the structure of the telephone, can solve the problems of the ineffective temperature control effect of the mobile phone, increase the volume of the mobile phone case, and be impractical, so as to increase the thermal sensitivity, control the temperature and protect the mobile phone. , the effect of fast thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

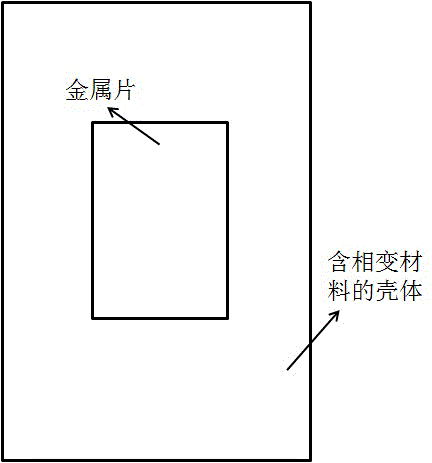

[0022] see Figure 1 to Figure 3 , Phase-change temperature-controlled mobile phone case, from the inside to the outside, including a graphite pad, a shell containing a phase-change material, and a metal sheet. The graphite pad is tightly attached to the inside of the shell containing the phase change material, and the metal sheet is embedded on the outside of the shell, such as figure 1 shown. The shell containing the phase change material is a phase change material-silica gel shell. The metal sheet is rectangular, the quantity is 1, and the thickness is 0.2mm, such as figure 2 and image 3 shown. The outer periphery of the phase-change material shell is provided with convex edges and holes matching with the mobile phone, and a cavity is arranged inside.

Embodiment 2

[0024] Phase-change temperature-controlled mobile phone case, from the inside to the outside, including a graphite pad, a shell containing a phase-change material, and a metal sheet. The graphite pad is tightly attached to the inner side of the shell containing the phase change material, and the metal sheet is embedded on the outer side of the shell. Housings containing phase change materials are phase change material-plastic housings. The metal sheet is rectangular, the number is 5, and the thickness is 0.5mm, such as Figure 4 shown. The outer periphery of the phase-change material shell is provided with convex edges and holes matching with the mobile phone, and a cavity is arranged inside.

Embodiment 3

[0026] Phase-change temperature-controlled mobile phone case, from the inside to the outside, including a graphite pad, a shell containing a phase-change material, and a metal sheet. The graphite pad is tightly attached to the inner side of the shell containing the phase change material, and the metal sheet is embedded on the outer side of the shell. Housings containing phase change materials are phase change material-metal housings. The metal sheet is heart-shaped, the quantity is 1, and the thickness is 0.8mm, such as Figure 5 shown. The outer periphery of the phase-change material shell is provided with convex edges and holes matching with the mobile phone, and a cavity is arranged inside.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com