Outer rotor permanent magnet motor for cooling fan of direct-cooled thermal power plant

A permanent magnet motor and cooling fan technology, applied in the direction of cooling/ventilation devices, electrical components, electromechanical devices, etc., can solve the problems of low efficiency, high maintenance cost, shortened bearing life, etc., to improve overall efficiency, excellent energy saving effect, Effect of drive chain shortening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

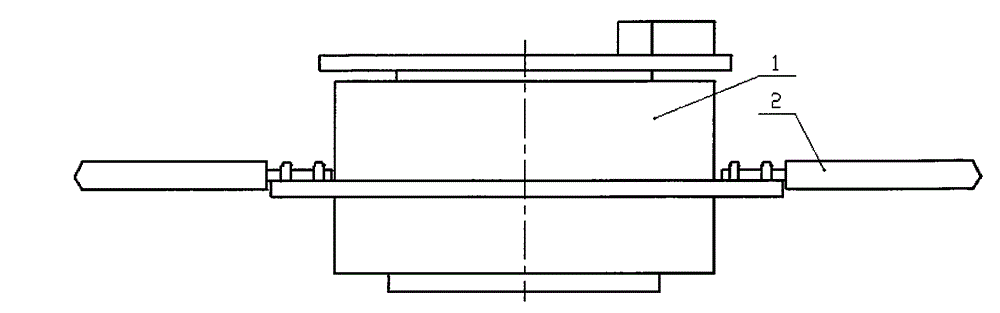

[0013] Image 6 Among them, the junction box (1) is fixed on the top of the stator, the stator (2) has a hollow structure inside, and the heat dissipation ribs (4) are arranged on the surface, the rotor (3) rotates, and the cooling fan motor (6) in the cooling fan (5) is fixed on the stator (2) Inside, fan blades are connected to the middle of the rotor (3).

[0014] Figure 7 Among them, the junction box (1) is fixed on the top of the stator, the stator (2) has a hollow structure inside, and the heat dissipation ribs (4) are arranged on the surface, the rotor (3) rotates, and the cooling fan motor (6) in the cooling fan (5) is fixed on the stator (2) Inside, the fan blades are attached to the bottom of the rotor (3).

[0015] Figure 8 Among them, the junction box (1) is fixed on the top of the stator, the stator (2) has a hollow structure inside, and the heat dissipation ribs (4) are arranged on the surface, the rotor (3) rotates, and the fan blades are connected to the m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com