A solid phase synthesis co 2+ Doped bismuth fluoride lithium ion battery cathode material and preparation method thereof

A lithium-ion battery, cathode material technology, applied in battery electrodes, secondary batteries, circuits, etc., can solve problems such as unpredictable effects and complex parent action mechanism, achieve low equipment requirements, excellent electrochemical performance, and avoid side reactions product effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

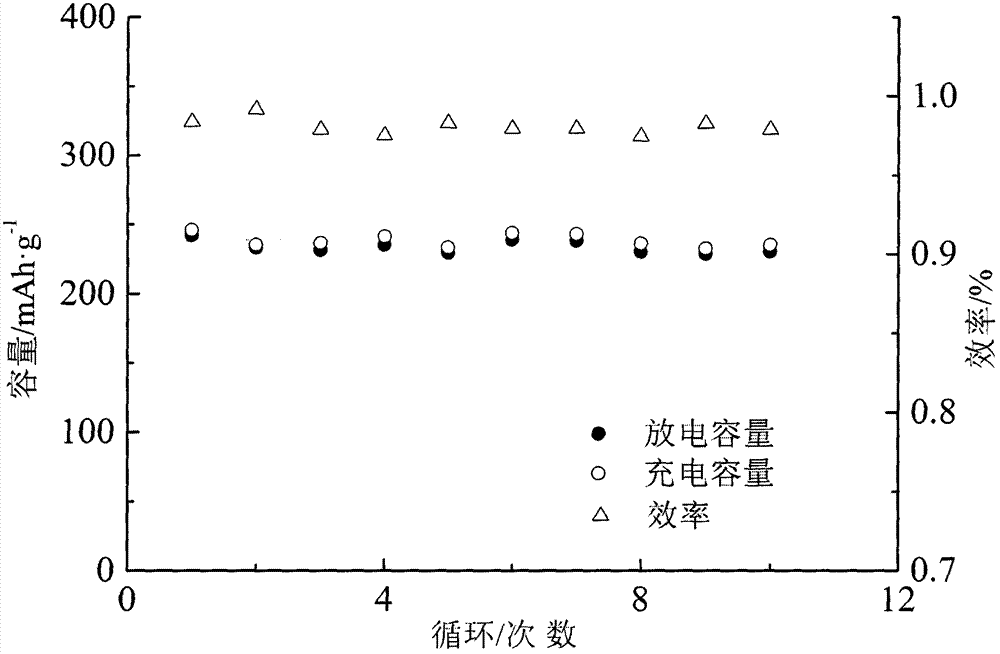

Image

Examples

Embodiment 1

[0015] Embodiment 1: put bismuth nitrate pentahydrate, bismuth nitrate pentahydrate substance amount 0.5% cobalt nitrate hexahydrate and bismuth nitrate pentahydrate quality 0.5% perfluoroheptanoic acid and put into ball mill after mixing, the mass ratio of ball mill and material is 20:1, ball milled for 10 hours at a speed of 200 rpm, and this material was called material I; tetra-n-butylammonium fluoride, 0.5% Tween-60, tetra-n-butylammonium fluoride quality 2% dehydrated alcohol of the quality of n-butyl ammonium fluoride is mixed and put into a ball mill, the mass ratio of the ball mill and the material is 20:1, ball milled at a speed of 200 rpm for 10 hours, and this material is called material II; Put material I and material II into the ball mill according to the ratio of the amount of bismuth salt in material I to the amount of quaternary ammonium salt in material II in the ratio of 1:3, the mass ratio of ball mill and material is 20:1, and at the same time Fill the bal...

Embodiment 2

[0016]Example 2: Put bismuth chloride, 1% cobalt oxalate tetrahydrate and 2,2-difluorocyclopropanecarboxylic acid with 1% bismuth chloride mass into a ball mill, and the ball mill is mixed with the material Mass ratio is 20: 1, with 200 revolutions / minute speed ball milling 10 hours, this material is called material I; 3% dehydrated alcohol of the quality of methyl ammonium fluoride is mixed and put into a ball mill, the mass ratio of the ball mill and the material is 20:1, and ball milled at a speed of 300 rpm for 15 hours, this material is called material II; Material I and material II are put into the ball mill according to the ratio of the amount of bismuth salt in material I to the amount of quaternary ammonium salt in material II in the ratio of 1: 3, and the mass ratio of ball mill and material is 20: 1. Fill the ball mill tank with a mixed gas of nitrogen and ammonia with a volume ratio of 95:5 to one atmosphere, and mill at a speed of 350 rpm for 7 hours; take out the...

Embodiment 3

[0017] Example 3: Put bismuth chloride, cobalt chloride hexahydrate with 2% of bismuth chloride substance content and perfluoroglutaric acid with 2% of bismuth chloride mass into a ball mill, and the mass ratio of the ball mill to the material is 20 : 1, ball milled for 20 hours at a speed of 400 revs / min, and this material was called material I; benzyltrimethylammonium fluoride, 2% Span-80, 4% dehydrated alcohol of benzyltrimethylammonium fluoride mass is mixed and put into a ball mill. The mass ratio of the ball mill to the material is 20:1, and ball milled at a speed of 400 rpm for 20 hours. This material is called material II; put material I and material II into a ball mill according to the ratio of the amount of bismuth salt in material I to the amount of quaternary ammonium salt in material II in a ratio of 1:3, and the mass ratio of ball mill to material is 20:1 At the same time, the mixed gas of nitrogen and ammonia with a volume ratio of 95:5 and one atmospheric press...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com